Power battery heat dissipation and distribution system

A power battery and heat equalization technology, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of complex heat dissipation structure, poor heat dissipation and heat equalization effect, and affect the performance and life of power batteries, etc., and achieve thermal conductivity High, conducive to heat dissipation and heat uniformity, good heat dissipation and heat uniformity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

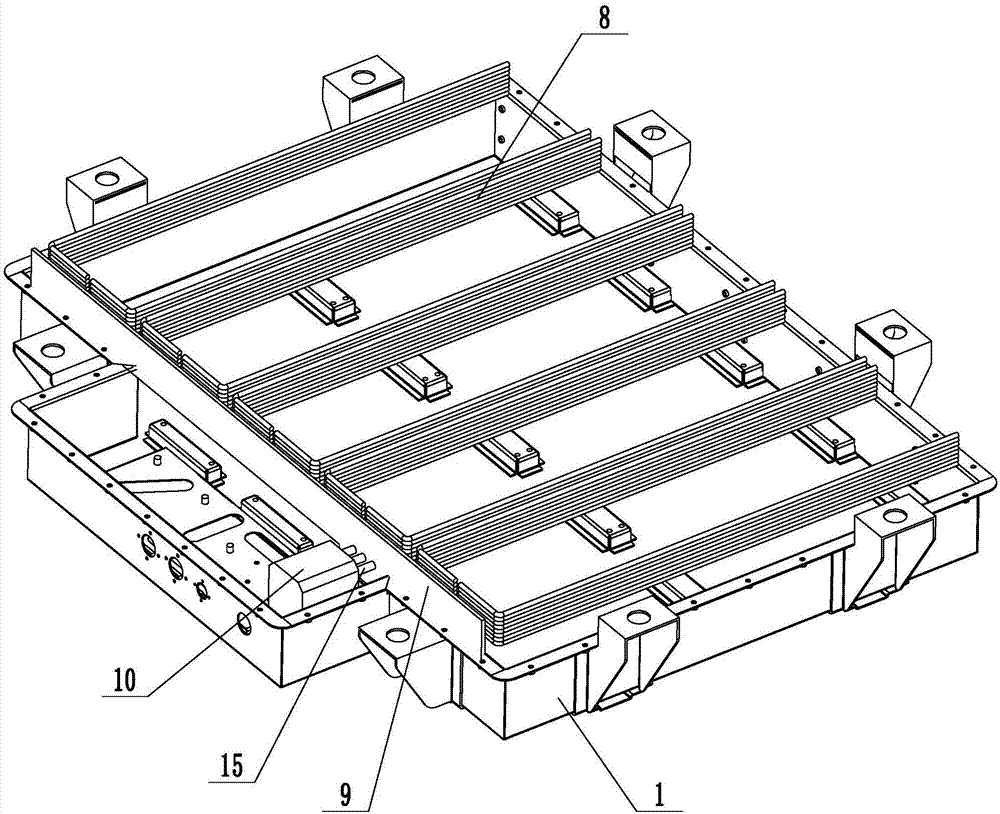

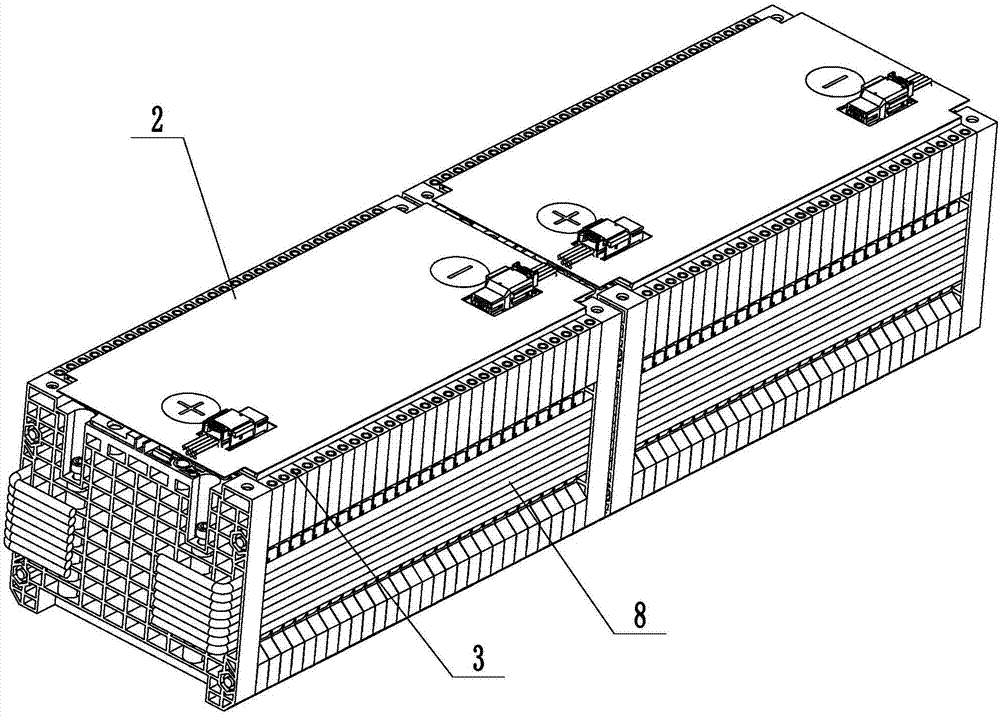

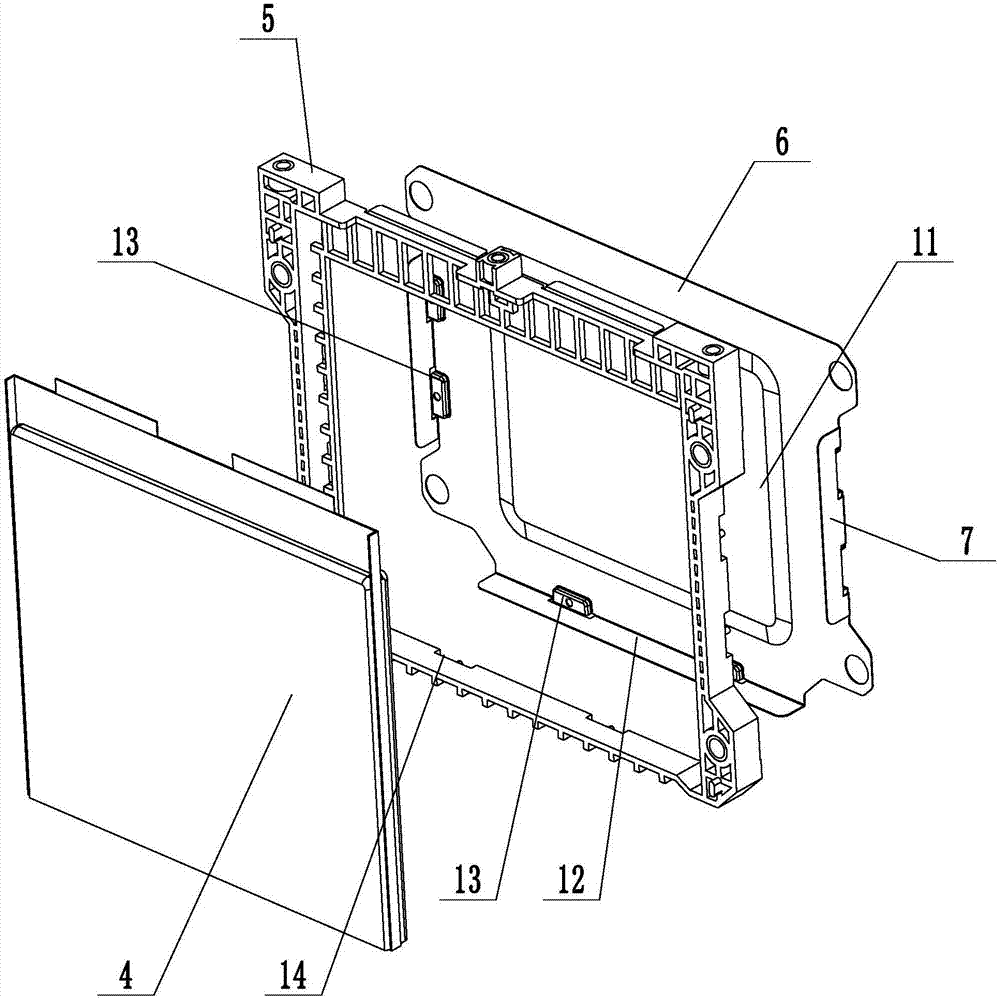

[0021] Embodiment 1: A power battery heat dissipation and heat equalization system (see attached Figures 1 to 3 ), including a base 1, a number of battery modules 2 installed on the base, the battery module includes a number of vertically arranged battery cells 3, and the battery cells include a battery cell 4, a bracket 5, and a superconducting heat transfer assembly 6, The superconducting heat transfer component is installed on the bracket and the front and rear sides are provided with heat transfer parts 7 protruding from the bracket. The battery cell is installed on the bracket and the right side surface is attached to the superconducting heat transfer component. The side surface is attached to the superconducting heat transfer component of the adjacent cell unit on the left, and the front and rear sides of the battery module are equipped with superconducting heat transfer bodies 8, and the heat transfer on the front and rear sides of the superconducting heat transfer comp...

Embodiment 2

[0023] Embodiment 2: A power battery heat dissipation and heat equalization system, its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, the superconducting heat transfer body is a long strip-shaped plate structure arranged vertically, and the superconducting heat transfer body The heating body is provided with a plurality of cooling holes arranged in parallel along the length direction, and the cooling holes run through both ends of the superconducting heat transfer body. Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com