Leakproof sealant for nickel-hydrogen battery and manufacturing method thereof

A nickel-metal hydride battery and sealant technology, applied in sealing materials, secondary batteries, airtight batteries, etc., can solve the problem of reducing the insulation level of the positive and negative electrodes of the battery and the DC system, easily reducing the sealing performance of the sealant, and reducing the use of batteries. life and other issues, to ensure normal service life and performance, reduce flow performance, and achieve the effect of strong sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, a leak-proof nickel-metal hydride battery, including a battery shell, a battery cell, an electrolyte and a sealant layer, the sealant layer is formed by a leak-proof sealant for a nickel-hydrogen battery, and the leak-proof sealant for a nickel-hydrogen battery is in parts by weight Including 18 parts of silicone rubber, 12 parts of olefin resin, 86 parts of normal alkanes, 3 parts of boric acid, 2.5 parts of titanium dioxide.

Embodiment 2

[0030] Embodiment 2, a leak-proof nickel-metal hydride battery, including a battery case, a battery cell, an electrolyte and a sealant layer, the sealant layer is formed by a leak-proof sealant for a nickel-hydrogen battery, and the leak-proof sealant for a nickel-hydrogen battery is in parts by weight Including 16 parts of silicone rubber, 12 parts of olefin resin, 89 parts of normal alkanes, 3 parts of boric acid, 1.5 parts of titanium dioxide.

[0031] As a reference example, a nickel-metal hydride battery includes a battery case, a cell, an electrolyte, and a sealant layer. The sealant layer is formed of a general sealant.

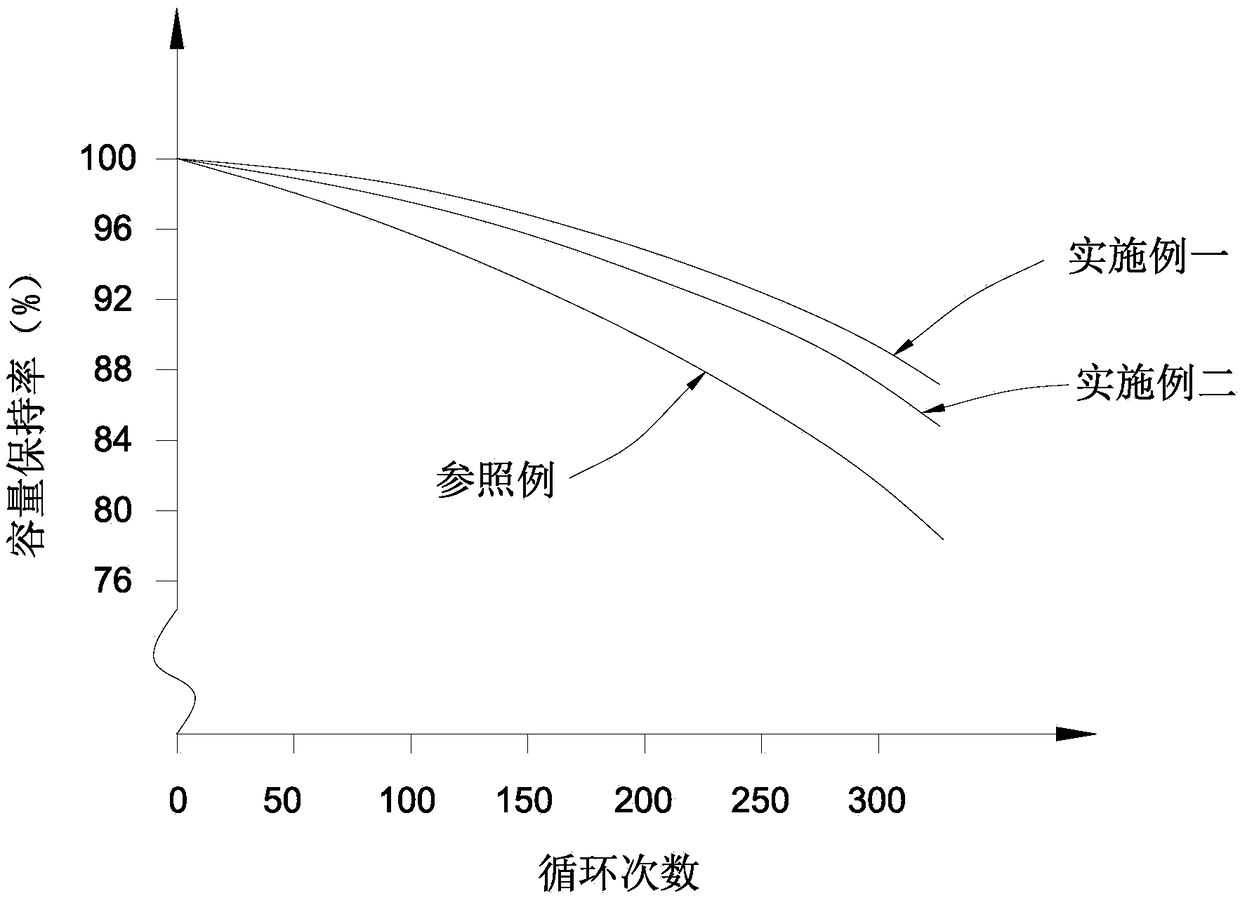

[0032] Such as figure 1 As shown, the abscissa is the number of cycles, and the ordinate is the capacity retention rate. The same number of cycles is used, and the capacity retention rate of the embodiment one and embodiment two of the leak-proof nickel-hydrogen battery obtained by the present invention is significantly higher than that of the prior ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com