Self-heat preserving fireproof brick

A fireproof brick and self-insulation technology, applied in the field of exterior wall bricks, can solve the problems of fire spread, heavy on-site workload of construction workers, loss of personnel and property, etc., to ensure safe use and service life, save multi-process construction, and avoid Effect of major loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

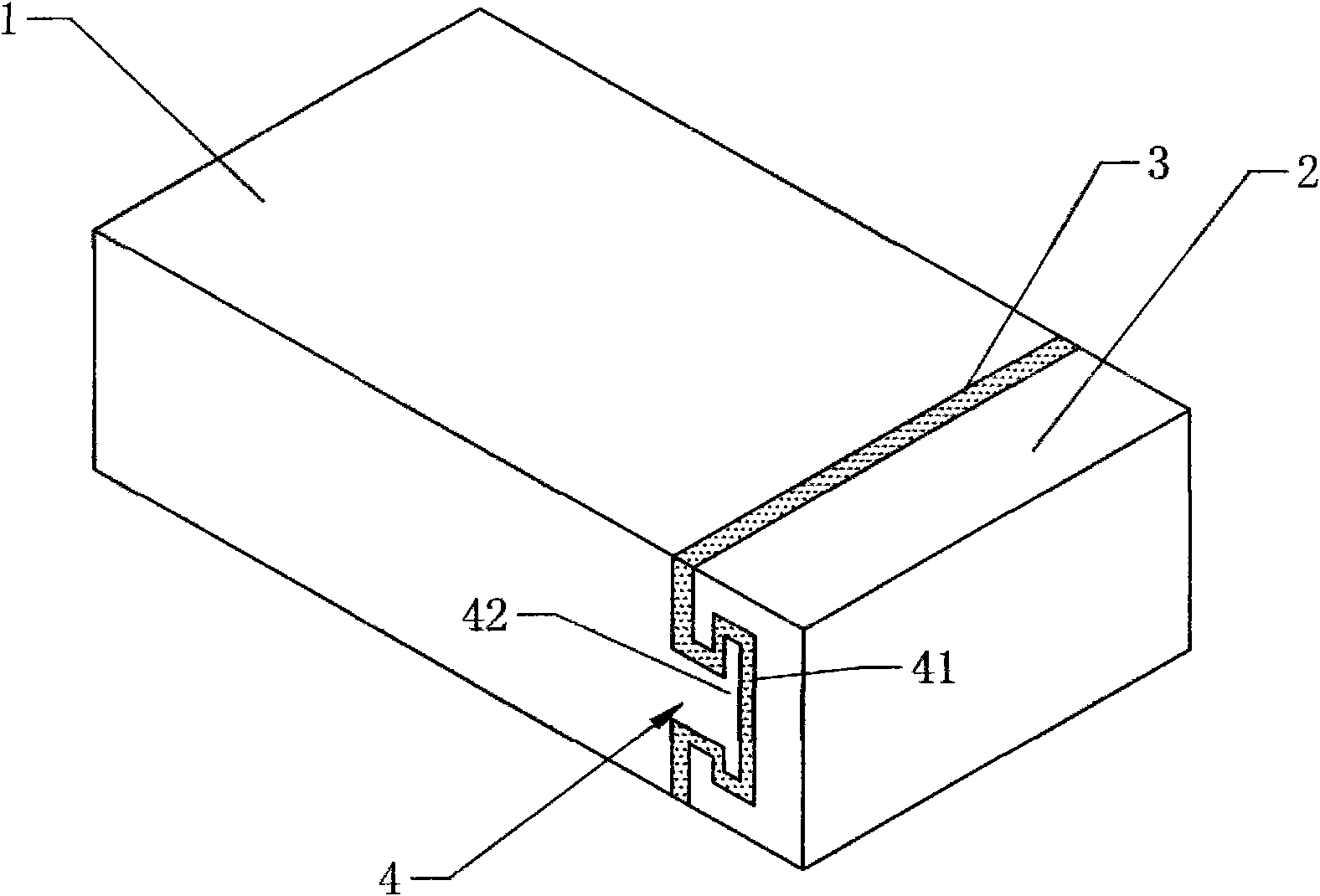

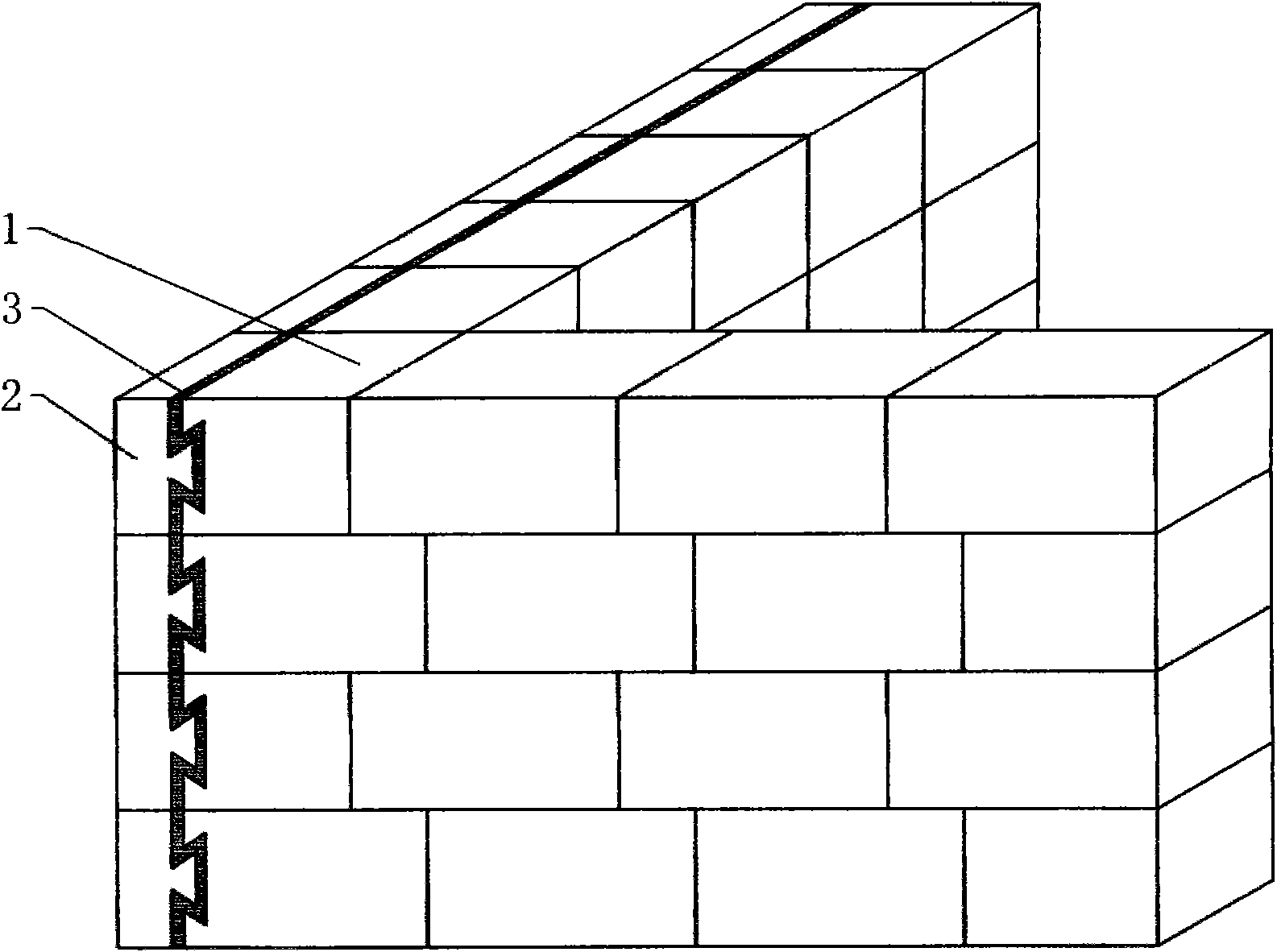

[0020] Embodiment 1: a kind of self-insulating fireproof brick, such as figure 1 As shown, it includes a load-bearing block 1, and the load-bearing block 1 is used as the load-bearing of the outer wall. The self-insulating fireproof brick also includes a protective block 2, and the gap between the protective block 2 and the load-bearing block 1 is Through the clamping of the coupling structure 4 , an insulating layer 3 is provided at the clamping joint between the protective block 2 and the load-bearing block 1 . The insulation layer 3 is an insulation mortar layer. The coupling structure 4 includes a groove 41 disposed on the protective block 2 and a protrusion 42 disposed on the bearing block 1, the protrusion 42 is clamped in the groove 41, the The thermal insulation layer 3 is arranged in the gap between the bump 42 and the groove 41 , that is to say, the thermal insulation mortar is poured into the gap between the bump 42 and the groove 41 and solidified to form the ther...

Embodiment 2

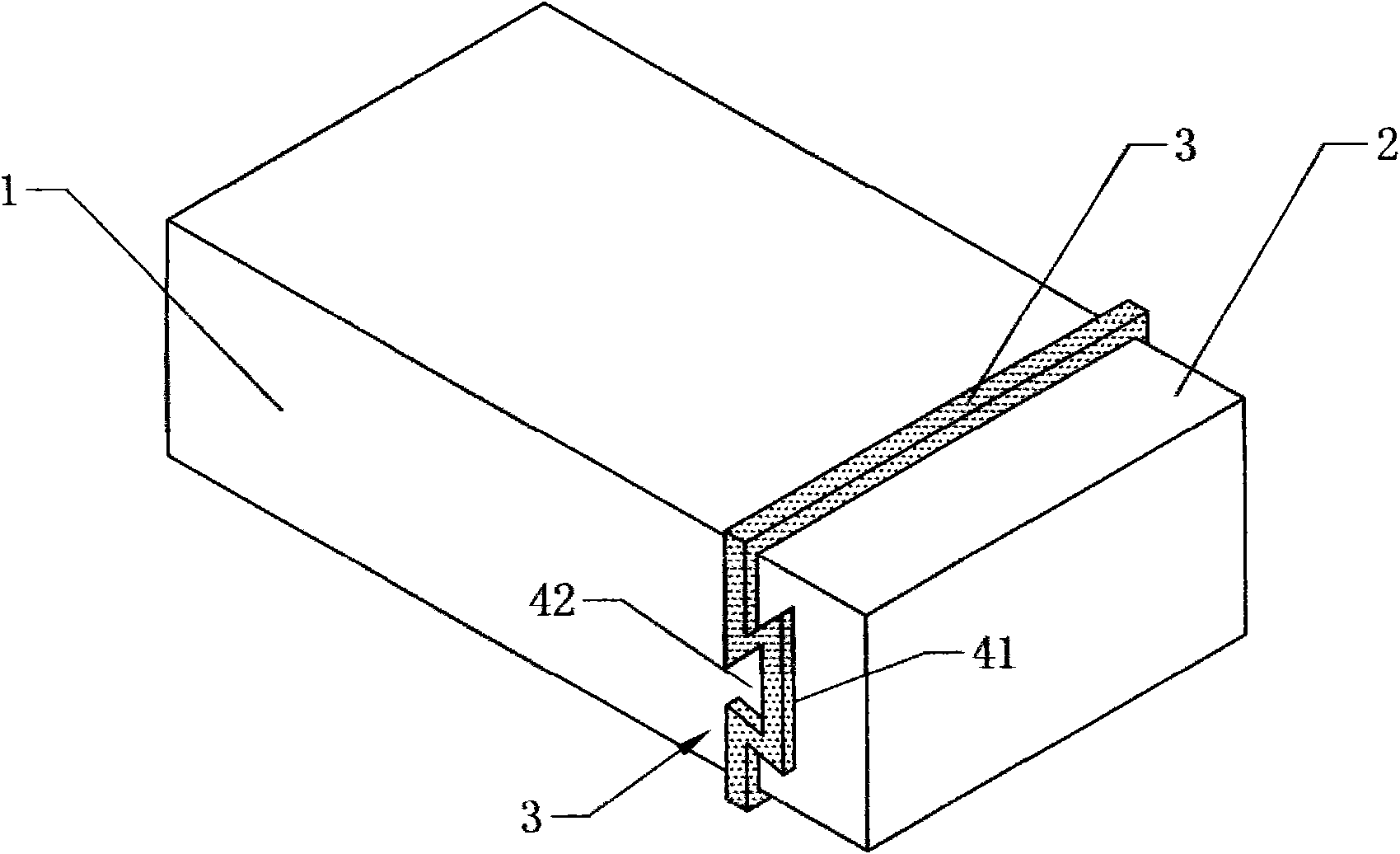

[0021] Embodiment 2: A kind of self-insulating fireproof brick, such as figure 2 As shown, the structure is basically the same as that of Embodiment 1, except that the groove 41 is a dovetail groove, and the bump 42 is a trapezoidal bump 42 . The surrounding profile of the thermal insulation layer 3 is higher than the corresponding surrounding surfaces of the load-bearing block 1 and the protective block 2, and the insulation layer 3 of two adjacent self-insulating fireproof bricks is not affected by the presence of bonding mud. Just can contact close, thereby, the insulation layer 3 of all self-insulation fireproof bricks that forms exterior wall has constituted a tight whole insulation wall layer together, is more conducive to the insulation of house like this, improves insulation effect.

[0022] Of course, the coupling structure 4 may also include a protrusion 42 disposed on the protective block 2 and a groove 41 disposed on the bearing block 1, and the protrusion 42 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com