Anti-UV (Ultraviolet) screw protecting sleeve and preparation method thereof

A technology for protective sleeves and screws, applied to nuts, bolts, mechanical equipment, etc., can solve the problems of no anti-oxidation, anti-UV, and increase the cost of use, so as to ensure quality and service life, avoid damage, and prevent safety problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

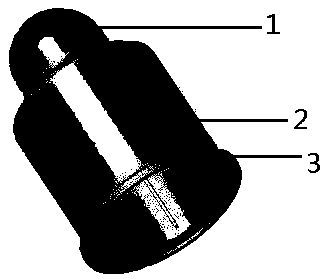

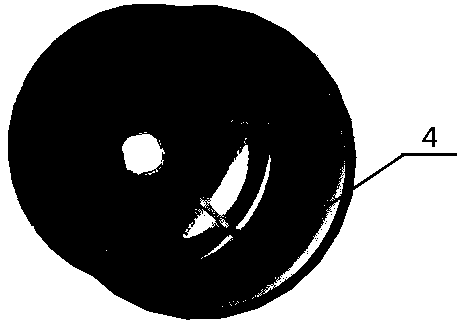

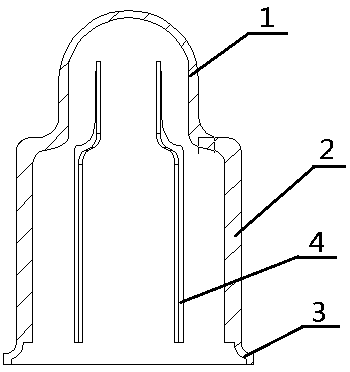

[0031] An anti-UV screw protective sleeve, the protective sleeve is one-time injection molding, the whole is made of elastic plastic, including a ring-shaped base 3 and a sleeve hole 2, the sleeve hole 2 is a hollow cylindrical structure, and its inner diameter is determined by the upper Incremental to the bottom, the upper part of the sleeve hole 2 is provided with a pull-out part 1 with a closed upper end and an open lower end. Slightly smaller, the shape and size of the sleeve hole 2 are adapted to the outer contour shape and size of the screw, and the inside of the sleeve hole 2 and the dialing part 1 are provided with a tooth structure.

[0032] The anti-UV screw protective cover is composed of the following components by mass fraction: polyethylene resin 30%, PVC resin 51%, white carbon black 2%, dibasic lead phosphite 2%, phenyl o-hydroxybenzoate 0.2%, Polypropylene grafted maleic anhydride 2.5%, n-octadecyl propionate 0.15%, lauroyl peroxide 3%, nanoscale composite hyd...

Embodiment 2

[0038] An anti-UV screw protective sleeve, the protective sleeve is one-time injection molding, the whole is made of elastic plastic, including a ring-shaped base 3 and a sleeve hole 2, the sleeve hole 2 is a hollow cylindrical structure, and its inner diameter is determined by the upper Incremental to the bottom, the upper part of the sleeve hole 2 is provided with a pull-out part 1 with the upper end closed and the lower end open. Small, the shape and size of the sleeve hole 2 is compatible with the external profile shape and size of the screw, and the inside of the sleeve hole 2 and the dialing part 1 are provided with a tooth structure.

[0039] The anti-UV screw protective cover is composed of the following components by mass fraction: polyethylene resin 40%, PVC resin 45%, white carbon black 3%, dibasic lead phosphite 1.5%, ultraviolet absorber UV-P 0.3%, Chlorinated polypropylene 2%, dilauryl thiotripropionate 0.2%, m-toluoyl chloride 3%, nanoscale composite hydroxide-i...

Embodiment 3

[0045]An anti-UV screw protective sleeve, the protective sleeve is one-time injection molding, the whole is made of elastic plastic, including a ring-shaped base 3 and a sleeve hole 2, the sleeve hole 2 is a hollow cylindrical structure, and its inner diameter is determined by the upper Incremental to the bottom, the upper part of the sleeve hole 2 is provided with a pull-out part 1 with a closed upper end and an open lower end. Small, the shape and size of the sleeve hole 2 is compatible with the external profile shape and size of the screw, and the inside of the sleeve hole 2 and the dialing part 1 are provided with a tooth structure.

[0046] Polyethylene resin 44%, PVC resin 35%, white carbon black 5%, dibasic lead phosphite 2%, 2-hydroxy-4-methoxybenzophenone 0.4%, methacrylic acid-styrene-butylene 2% diene polymer, 0.3% bis-stearyl thiodipropionate, 4% sulfacetamide, 3% nanoscale composite hydroxide-inorganic filler powder, 2.3% dispersant, 2, 4, 6 -Tris(2'-butoxyphenyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com