Deceleration cylinder cut-off

A cylinder, air technology used in electrical controls, fuel air intakes, combustion engines, etc., to address issues such as hindering commercial adoption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

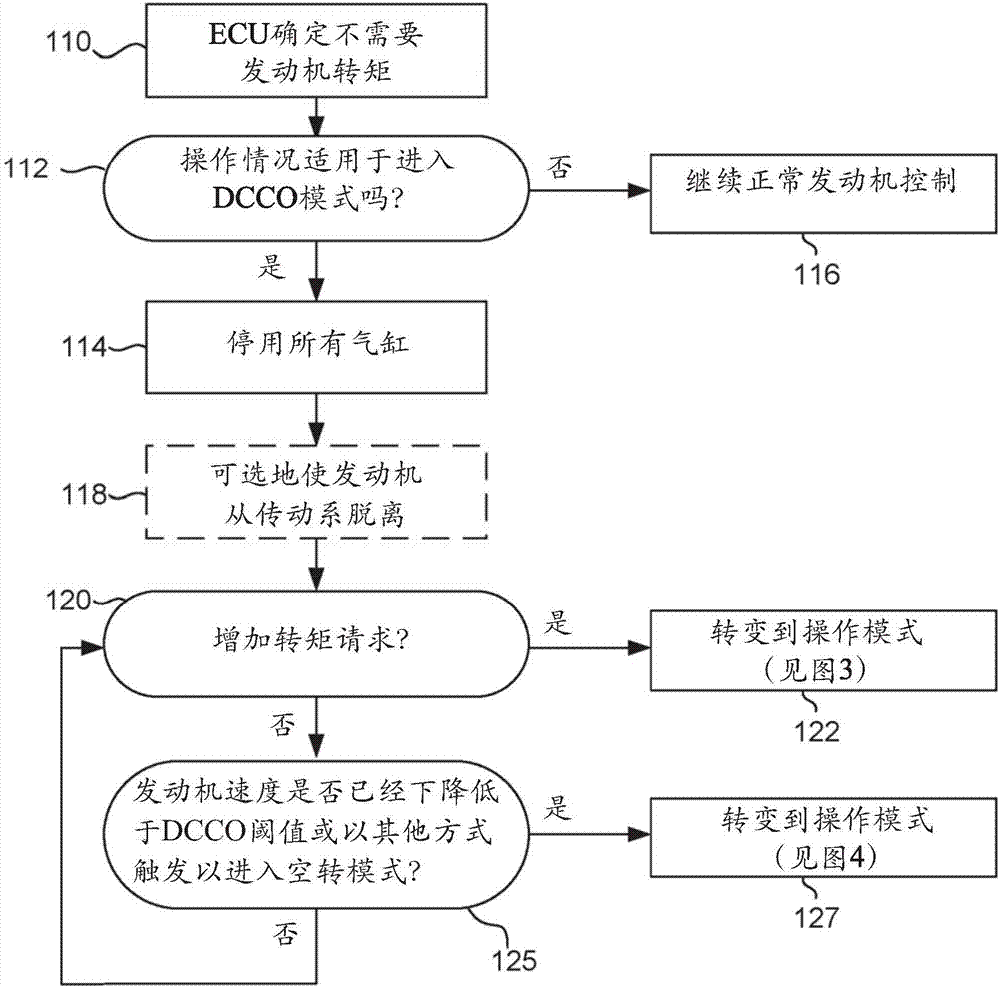

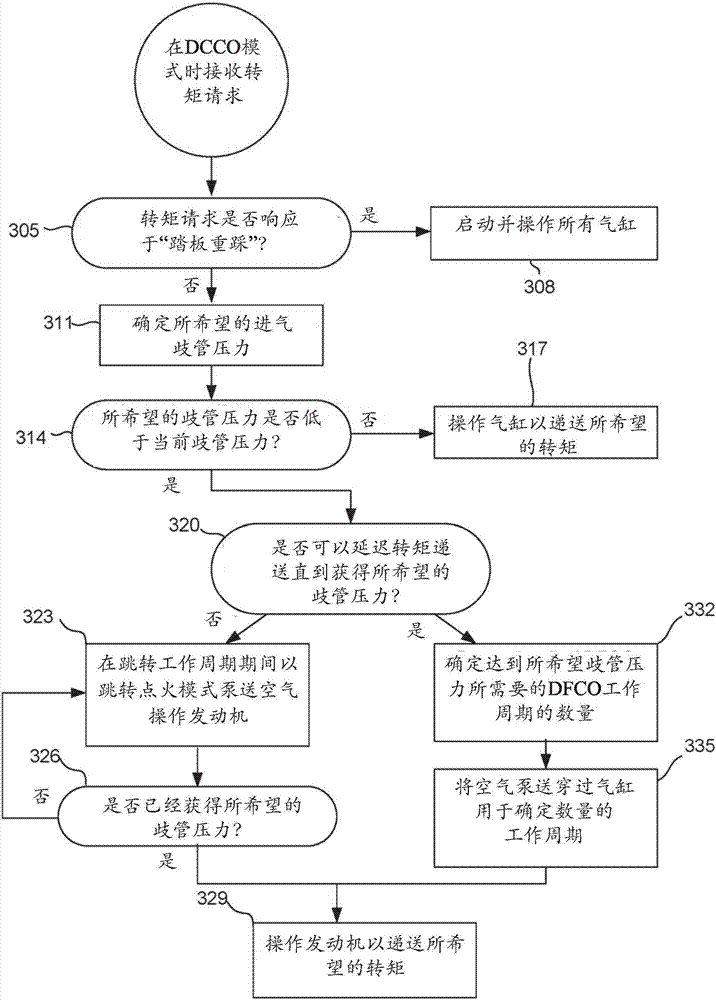

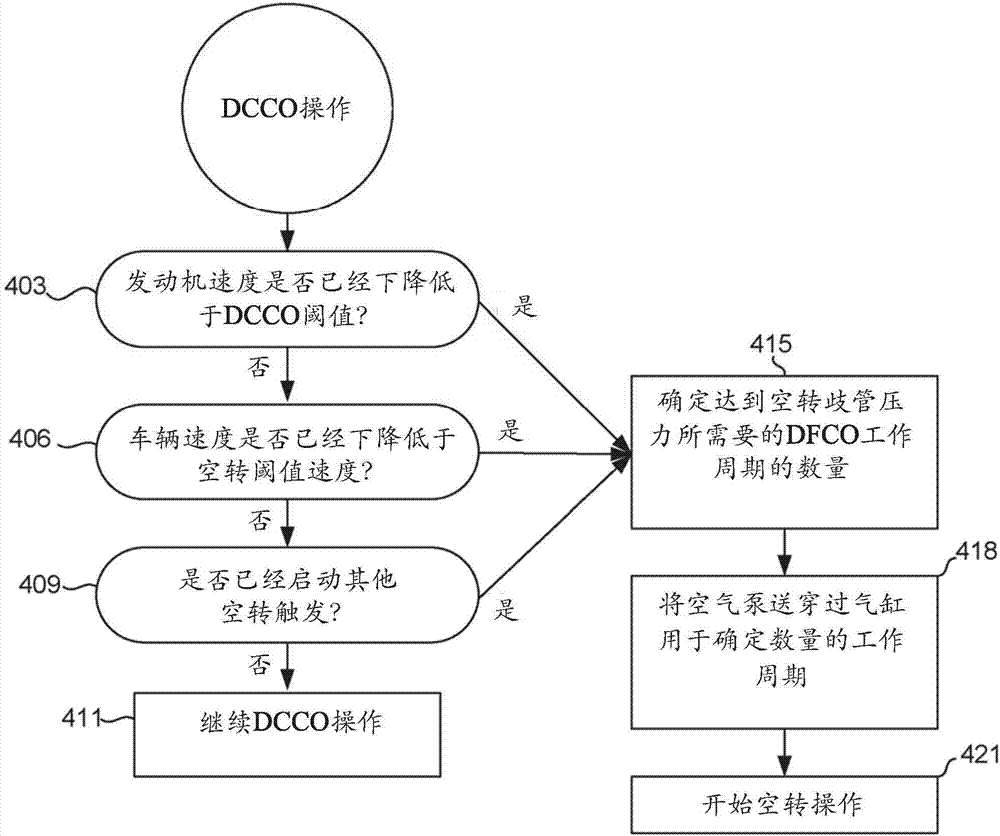

[0021] Some control strategies for supporting deceleration cylinder cut-off during operation of an internal combustion engine are described.

[0022] As noted in the background, there are several challenges associated with achieving deceleration cylinder cut-off. One such challenge is associated with intake manifold pressure. Specifically, when all cylinders are deactivated, no air exits the intake manifold. At the same time, leaks around the throttle valve and intake system will cause the manifold to fill towards atmospheric pressure. Therefore, when the cylinders re-engage, more torque than desired may be provided by each cylinder firing, which may result in undesirable NVH (noise, vibration and harshness) characteristics. One potential way to address NVH effects is to momentarily retard spark in a manner that reduces engine output enough to alleviate NVH issues. While this approach can work, it has the disadvantage of wasting fuel during the use of spark retarded cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com