Method for adjusting and adapting the working point of a hydraulic actuator

A technology for actuators and working points, applied to mechanical equipment, components with teeth, non-mechanical drive clutches, etc., can solve problems such as huge amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

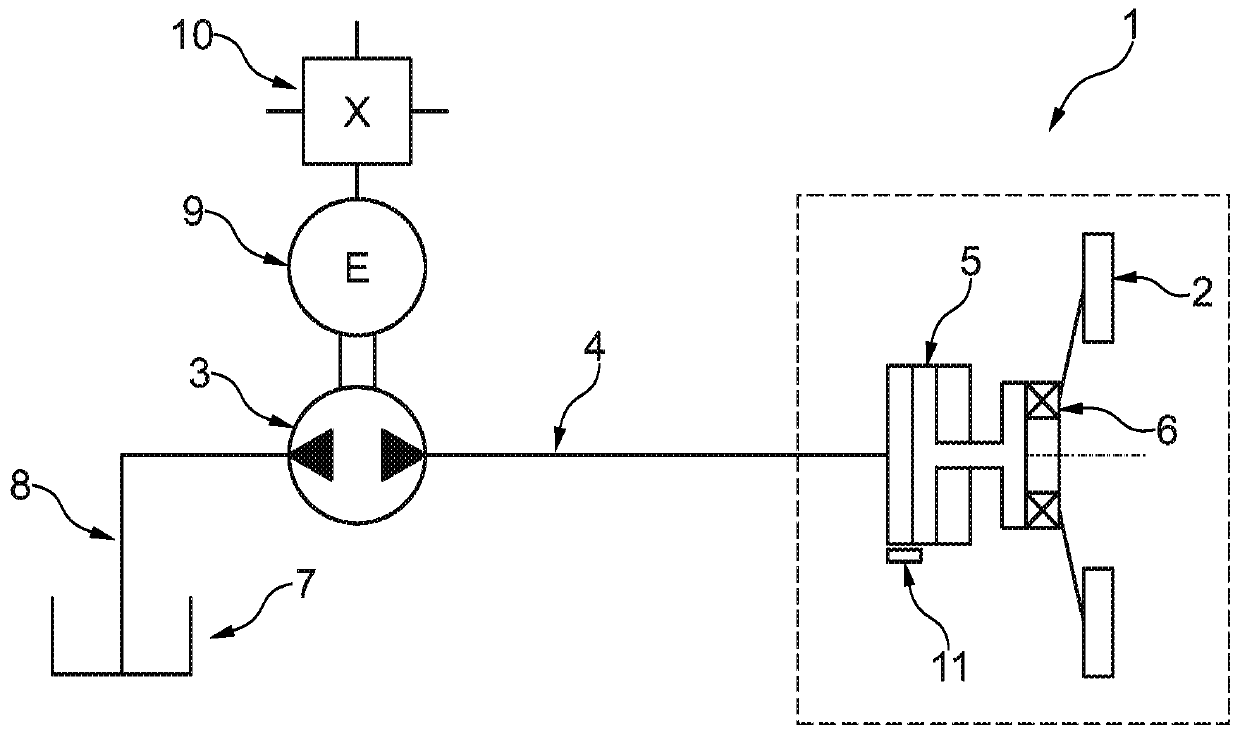

[0023] figure 1 is an exemplary embodiment of a hydraulic clutch actuator 1 according to the invention for use, for example, in a motor vehicle drive train, wherein the hydraulic clutch actuator 1 is used to actuate a clutch arrangement 2 . A volumetric flow source, designed for example as a pump 3 , is connected via a high-pressure hydraulic line 4 to a hydraulic cylinder 5 , which acts on the clutch device 2 via an engagement bearing 6 . The hydraulic fluid is sucked out of the hydraulic fluid tank 7 by the pump 3 through the low-pressure hydraulic line 8 , passed through the pump 3 , and delivered to the hydraulic cylinder 5 through the high-pressure hydraulic line 4 . The hydraulic fluid moves the piston of the hydraulic cylinder 5 whereby the engagement bearing 6 is moved and the clutch 2 is also moved.

[0024] The pump 3 is driven by the motor 9, and an angle sensor 10 is positioned on the motor 9 to measure the rotation angle of the motor 9. The rotational position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com