On-line sand removal apparatus for oil-gas pipelines

A technology for oil and gas pipelines and sand storage, applied in the direction of separating sediments by centrifugal force, chemical instruments and methods, separation methods, etc., can solve the problems of sand separation influence, doubtful separation effect, unreasonable form, etc. effective way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

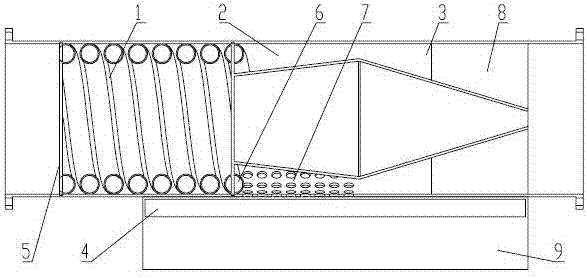

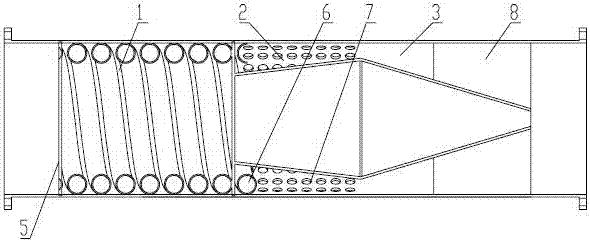

[0026] A kind of oil and gas pipeline on-line desanding device of the present invention will be further described below in conjunction with the accompanying drawings:

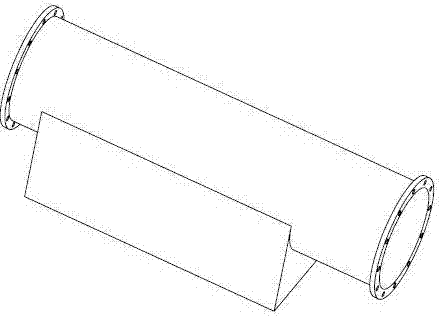

[0027] as attached figure 1 to attach Figure 4 As shown, an online sand removal device for oil and gas pipelines of the present invention includes a spiral separation section 1 , a swirl sand separation section 2 , a flow restoration section 3 and a sand storage chamber 4 .

[0028] The main body of the spiral separation section 1 is an axisymmetric double helical tube structure, and the spiral inlet end face 5 adopts a flat section and maximizes the flow section of the spiral tube inlet. Its detailed structure is shown in the attached Figure 5 Shown; The selection of the helix angle of the double helix tube 10 is 5 ° ~ 10 °, the helix angle of the double helix tube 10 should not only avoid the collision of the double helix tubes caused by too small, but also avoid the excessively long length of the helix se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com