All-in-one machine for cleaning plane glass and curved glass

A technology of curved glass and all-in-one machine, applied in the directions of dryer, drying gas arrangement, cleaning method and utensils, etc., can solve the problem of difficult to meet the cleaning of curved glass, achieve high safety and stability, improve cleaning quality and convenience cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

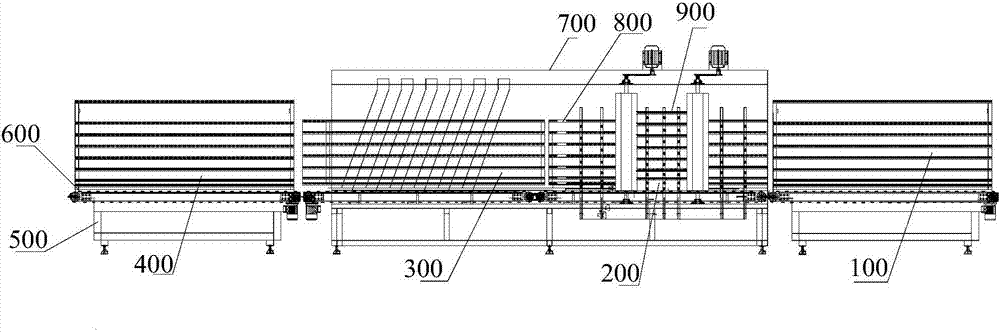

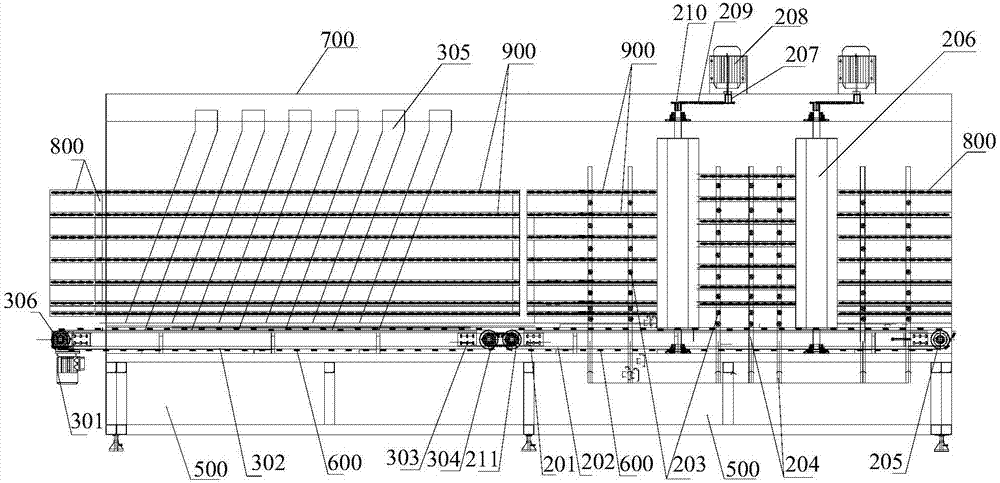

[0033] like Figure 1-Figure 8 As shown, a flat glass and curved glass cleaning integrated machine includes a frame 500, and the frame 500 is provided with a feeding section 100, a cleaning section 200, a drying section 300 and a discharging section 400; the cleaning section 200 and the drying section 300 All are located in the cleaning and drying box 700. The feeding section 100 and the discharging section 400 are independently provided with boxes.

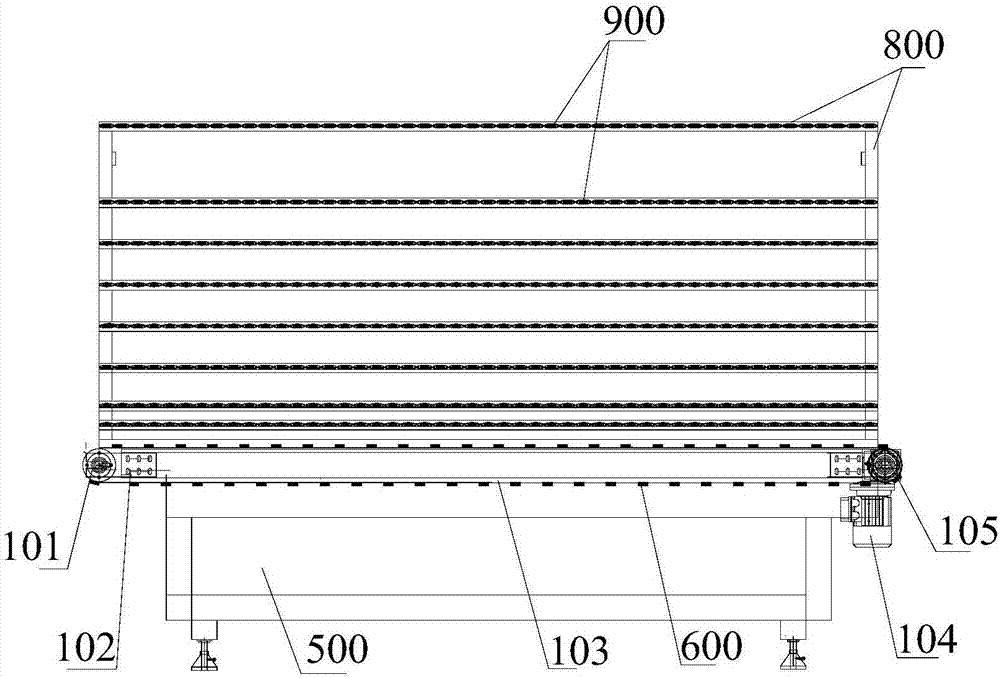

[0034] The feeding section 100, the cleaning section 200, the drying section 300, and the discharging section 400 are all provided with a vertical support 800 fixed on the frame 500, and the vertical support 800 is provided with a plurality of backrest wheels 900. The back-to-back wheels 900 are closely arranged, and two adjacent rows of back-to-back wheels 900 are arranged alternately to ensure the smooth transmission of curved glass such as corrugated glass.

[0035] The feed section 100 includes a feed section timing belt gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com