High-precision quick cutting device for building decorative boards

A technology for architectural decoration and rapid cutting, applied in metal processing and other directions, can solve the problems of small application scope, affecting production efficiency, and increasing the scrap rate of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

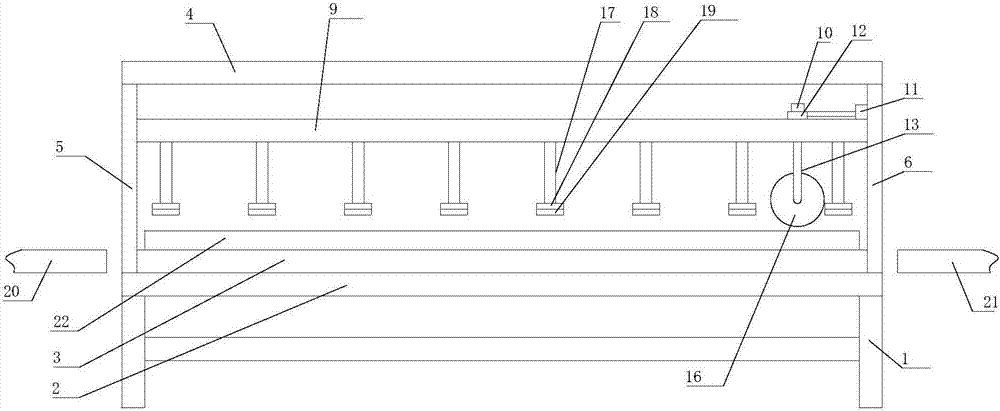

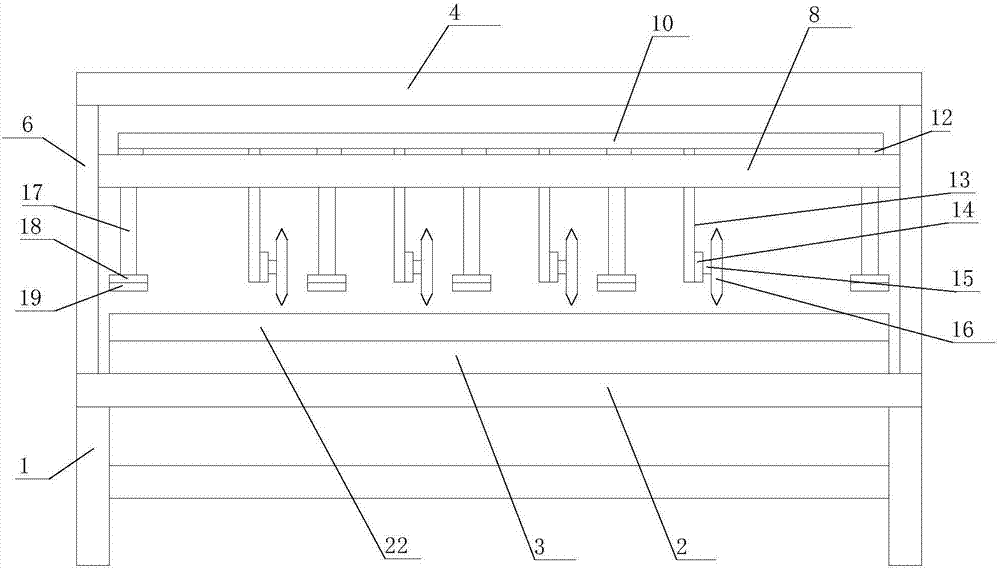

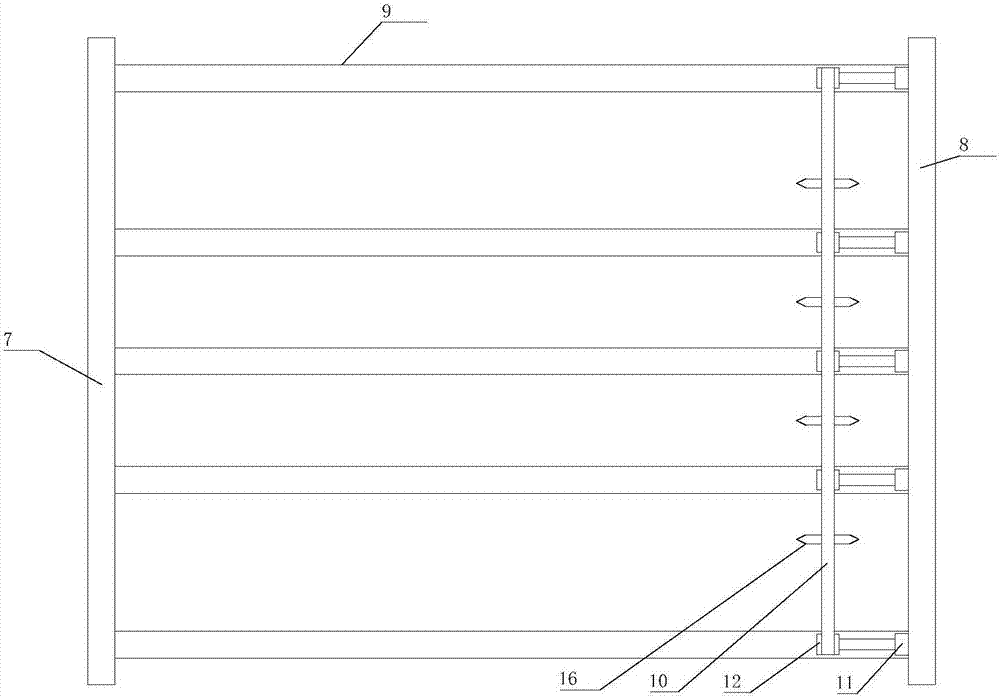

[0016] refer to Figure 1-Figure 3 , the present invention proposes a high-precision building decorative board fast cutting device, including a frame 1, a workbench 2, a cutting mechanism, and a controller, wherein:

[0017] The workbench 2 is horizontally installed on the frame 1, and the feed end of the workbench 2 and its discharge end are provided with a conveying roller set 3 for conveying the workpiece to be processed, and the feed end of the workbench 2 is provided with a conveying roller set 3. A first conveying mechanism 20 for conveying workpieces to be processed, and a second conveying mechanism 21 for conveying processed workpieces is provided at the discharge end of the workbench 2. The top of the workbench 2 is provided with a mounting frame 4 parallel to it, the two sides of the feed end of the workbench 2 are respectively provided with vertically arranged first side frames 5, and the two sides of the discharge end of the workbench 2 are respectively provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com