An automatic cutting device for building decorative panels

A cutting device and architectural decoration technology, applied in transportation and packaging, thin material processing, metal processing, etc., can solve the problems of small application range, poor cutting accuracy, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

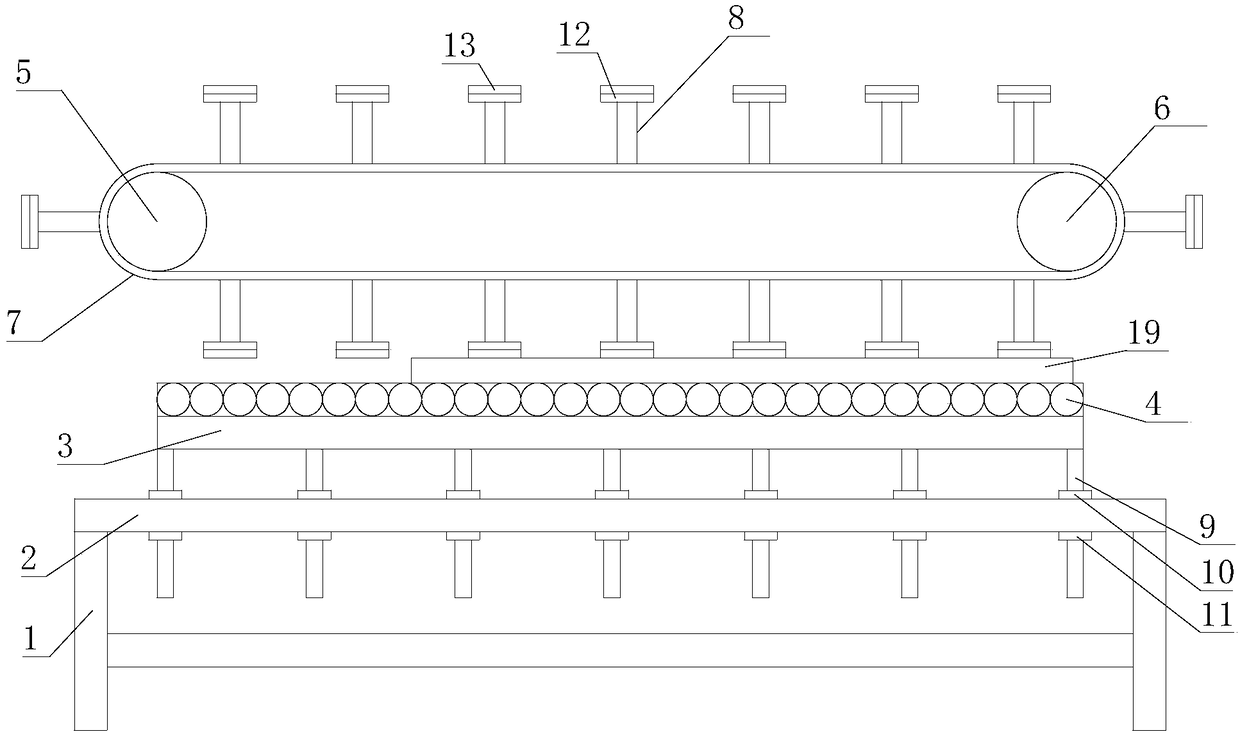

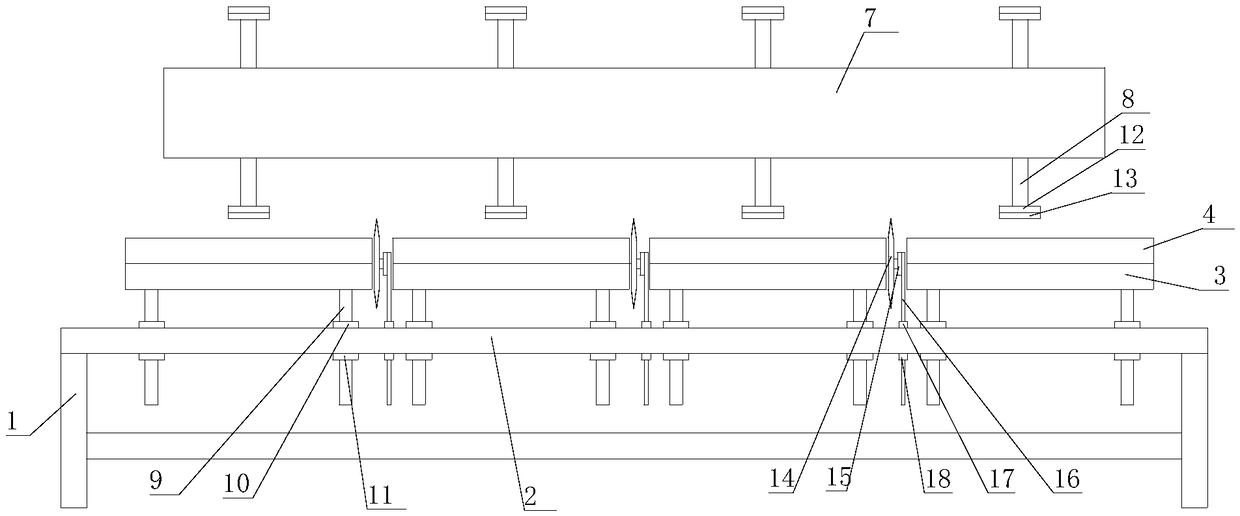

[0017] refer to figure 1 , figure 2 , the present invention proposes a fully automatic cutting device for building decorative panels, including a frame 1, a mounting table 2, a cutting mechanism, a platen mechanism, and a controller, wherein:

[0018] The installation table 2 is horizontally installed on the frame 1, and the cutting mechanism includes a plurality of cutting tables 3, which are arranged at intervals above the installation table 2 along the width direction of the installation table 2, and the plurality of cutting tables 3 are all parallel to the installation table 2 And the distance between a plurality of cutting tables 3 and the installation table 2 is equal, and the feeding end of the cutting table 3 and its discharge end are provided with a transfer roller group 4, and the conveying direction of the transfer roller group 4 is the same as the length of the installation table 2. The directions are consistent, and a cutting knife group for cutting workpieces i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com