Application method for classifier of waste tire fine rubber powder

A waste tire and classifier technology, which is applied in the field of resource recycling and comprehensive utilization, can solve the problems of fine rubber powder particles escaping from the environment, easy damage, and environmental noise pollution, so as to increase the effective screening area and avoid scorching and carbonization of rubber powder , increase the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

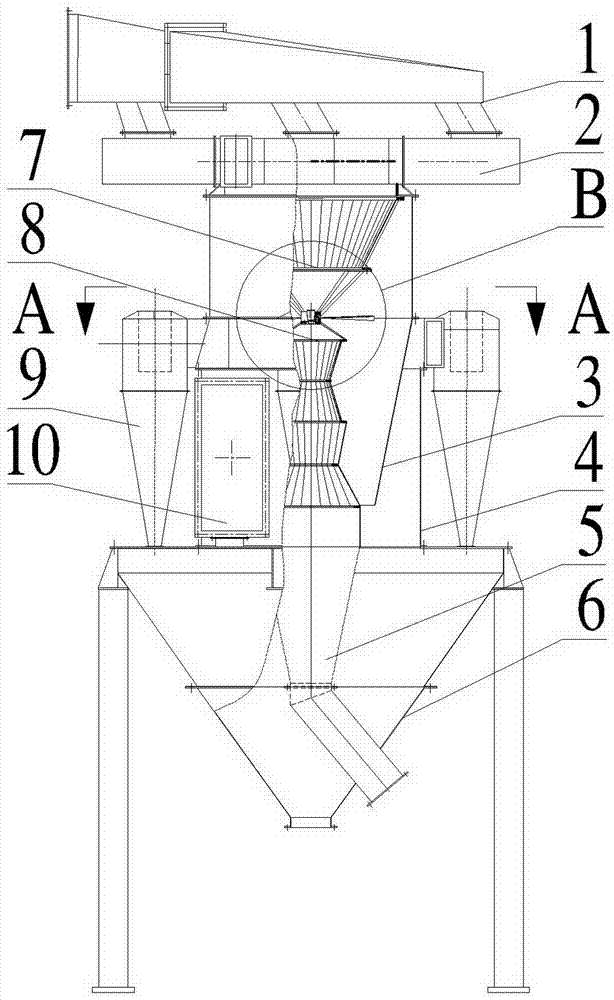

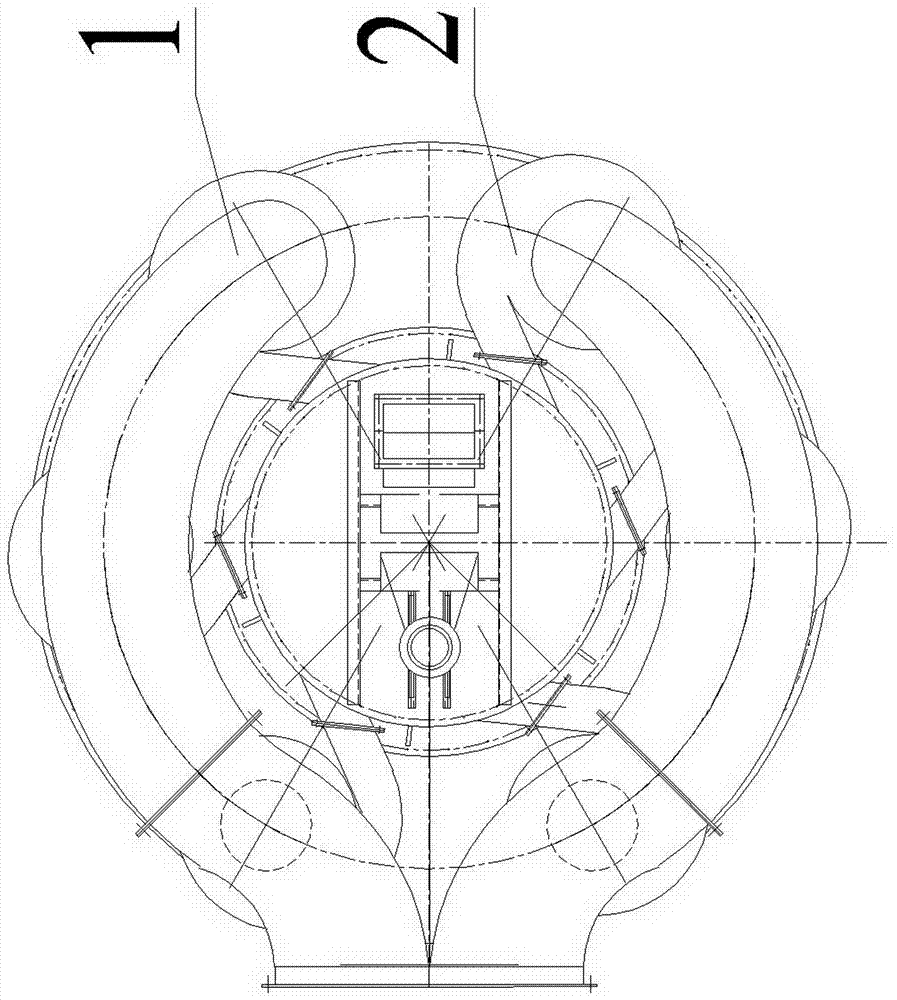

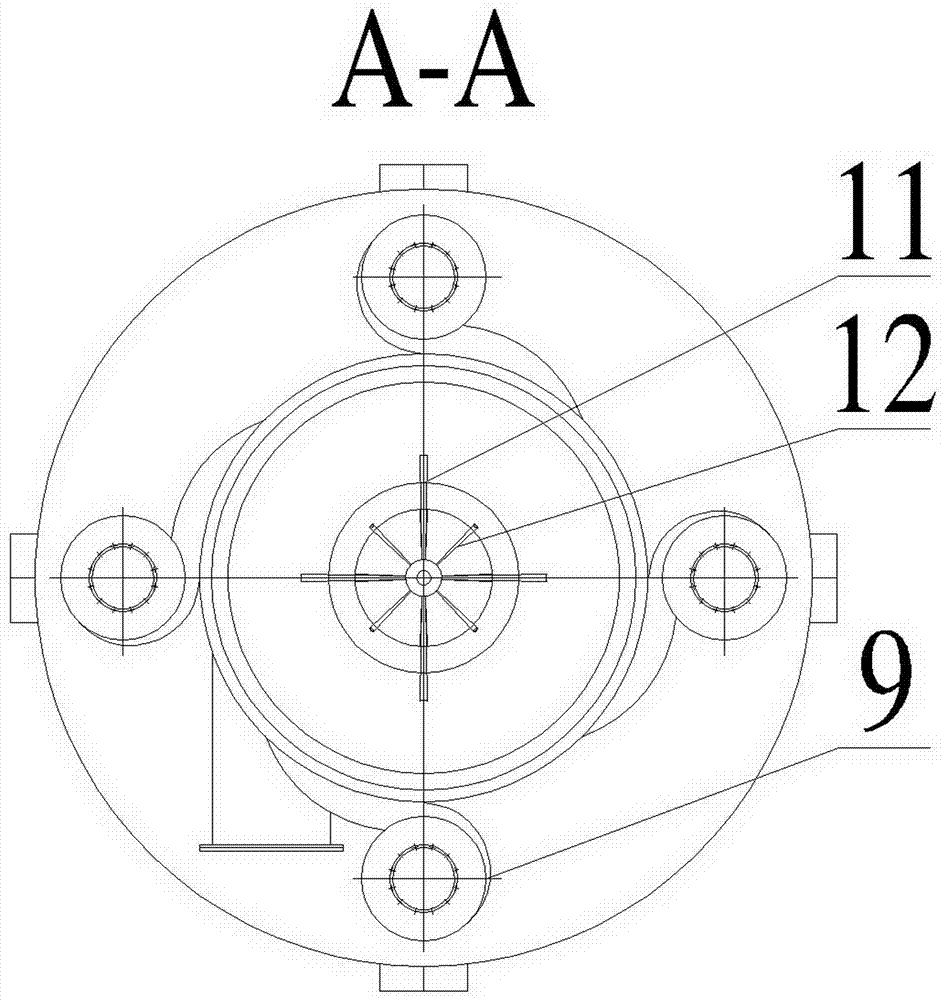

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of use method of waste tire fine rubber powder classifier is characterized in that:

[0023] Step 1, the airflow output from the steam protection mill carries the waste tire rubber powder particles into the sump 1, and evenly distributes them into the scroll inlet assembly 2 through the sump 1, and then enters along the tangential direction of the circumference 6 of the fine-grade circumferential screen cage , flowing downwards along the inner wall of the fine-grade circumferential sieve cage 6, and separated by the sieve holes of the fine-grade circumferential sieve cage 6, the airflow carries the sorted out rubber powder of 38 mesh or more along the diverter skirt 3 to the bottom of the cylinder 4.

[0024] Step 2, when the air flow passes through the cross balance fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com