A kind of method for purifying citric acid from citric acid liquid

A citric acid solution and citric acid technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of the inability to increase the utilization rate of the resin, increase the number of resin regenerations, and increase the amount of waste liquid discharge, etc., to achieve saving Effects of enrichment cost, consumption reduction, and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

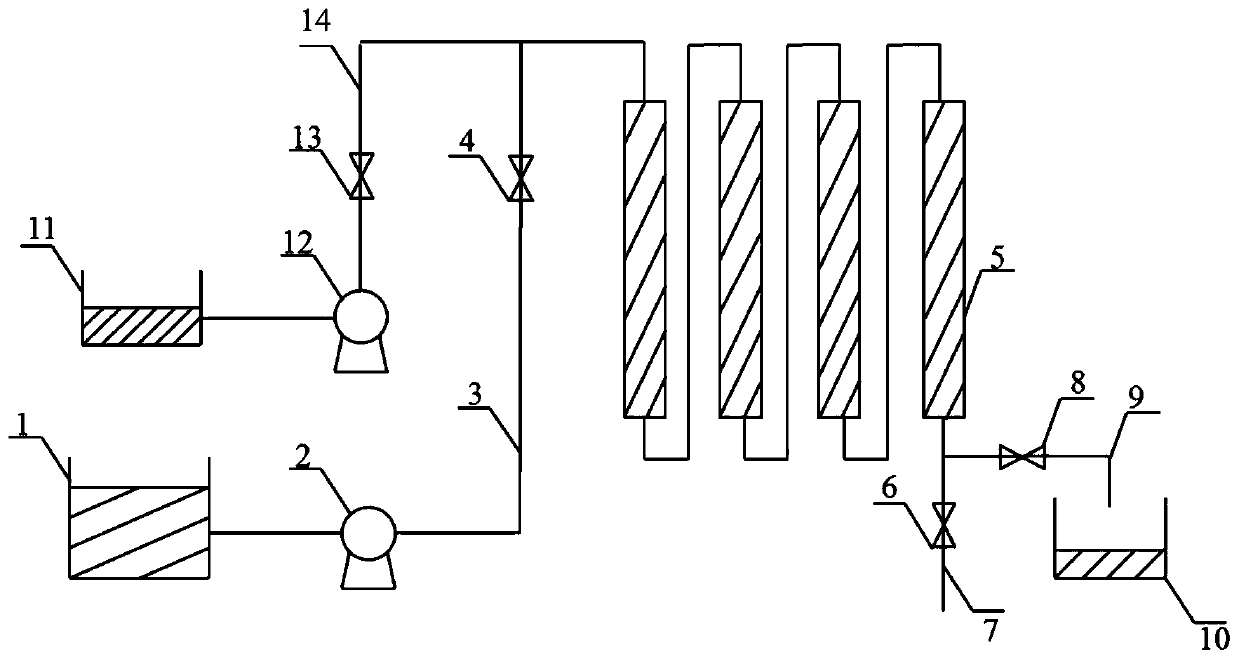

[0033] A method for purifying citric acid from a citric acid solution, the citric acid solution containing citric acid, chloride ions and sulfate ions, the method comprising the following steps:

[0034] (1) First, open the feed valve 4 and the discharge valve 8;

[0035] (2) Then, turn on the constant flow pump 2, and remove the citric acid solution (with citric acid mass concentration of 10%, sulfate ion concentration of 1g / L, and chloride ion concentration of 0.5g / L) from the raw material at a flow rate of 0.1L / h The liquid storage tank 1 enters the ion exchange column 5 through the feed pipe 3;

[0036] (3) Then, citric acid flows into the pre-set product storage tank 10 through the discharge valve 9;

[0037] (4) Finally, measure the chloride ion and sulfate ion concentration in the effluent of the discharge pipe 9 every 10 mL, stop collecting citric acid when the chloride ion concentration in the solution is higher than 6 mg / L, and close the outlet valve 8, constant flow Pump 2...

Embodiment 2

[0043] A method for purifying citric acid from a citric acid solution, the citric acid solution containing citric acid, chloride ions and sulfate ions, the method comprising the following steps:

[0044] (1) First, open the feed valve 4 and the discharge valve 8;

[0045] (2) Then, turn on the constant flow pump 2, and remove the citric acid solution (with citric acid mass concentration of 15%, sulfate ion concentration of 3g / L, chloride ion concentration of 1g / L) from the raw material solution at a flow rate of 0.3L / h The storage tank 1 enters the ion exchange column 5 through the feed pipe 3;

[0046] (3) Then, citric acid flows into the pre-set product storage tank 10 through the discharge valve 9;

[0047] (4) Finally, measure the chloride ion and sulfate ion concentration in the effluent of the discharge pipe 9 every 10 mL, stop collecting citric acid when the chloride ion concentration in the solution is higher than 6 mg / L, and close the outlet valve 8, constant flow Pump 2, fe...

Embodiment 3

[0053] A method for purifying citric acid from a citric acid solution, the citric acid solution containing citric acid, chloride ions and sulfate ions, the method comprising the following steps:

[0054] (1) First, open the feed valve 4 and the discharge valve 8;

[0055] (2) Then, turn on the constant flow pump 2, and transfer the citric acid solution (in which the mass concentration of citric acid is 20%, the concentration of sulfate ion is 5g / L, and the concentration of chloride ion is 2g / L) from the raw material solution at a flow rate of 0.4L / h The storage tank 1 enters the ion exchange column 5 through the feed pipe 3;

[0056] (3) Then, citric acid flows into the pre-set product storage tank 10 through the discharge valve 9;

[0057] (4) Finally, measure the chloride ion and sulfate ion concentration in the effluent of the discharge pipe 9 every 10 mL, stop collecting citric acid when the chloride ion concentration in the solution is higher than 6 mg / L, and close the outlet val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com