A kind of graphene foam loaded nano-fe 3 o 4 Magnetic particle composite absorbing material and preparation method thereof

A composite wave absorbing material, graphene foam technology, applied in chemical instruments and methods, other chemical processes and other directions, can solve the problems that have not been reported yet, and the preparation of 3D graphene-supported magnetic particles is less researched, and achieves a green preparation process. , The effect of excellent absorbing performance and excellent electromagnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

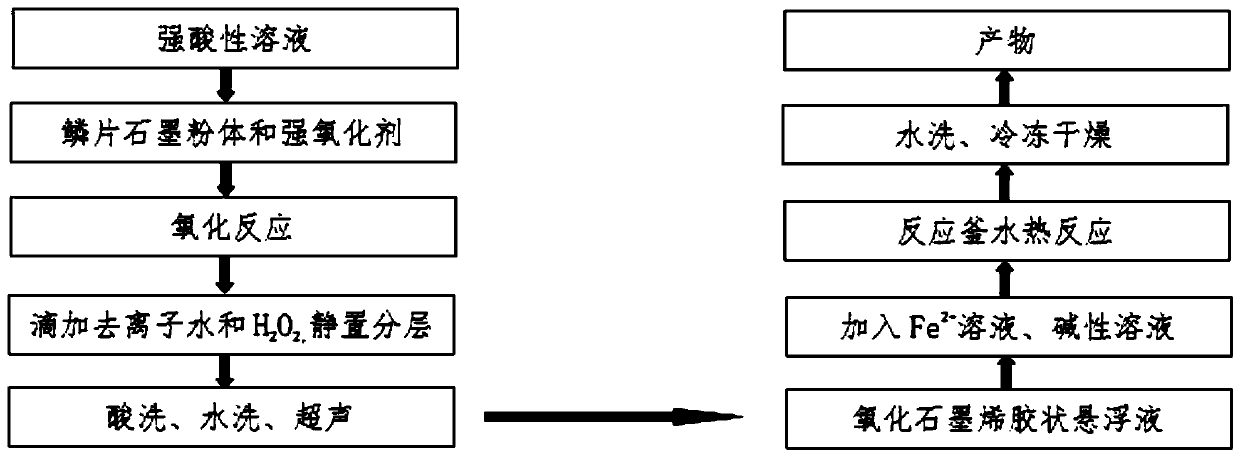

Method used

Image

Examples

Embodiment 1

[0030] Step 1: Mix 1.0g flake graphite, 23ml concentrated H 2 SO 4 Place in a 500ml three-necked flask, and stir evenly in an ice-water mixture at 0°C. Weigh 3.0 g of potassium permanganate, add slowly in batches, and control the temperature of the reaction system at 0-10° C. for 1 h. Then the system was moved into a 35°C water bath and reacted for 3h. After the reaction was finished, 50ml of distilled water was slowly added dropwise and reacted at 90°C for 0.5h. Finally, add 100ml of distilled water and 10ml of H 2 o 2 . The product was washed with 5% HCl and distilled water to pH=6-7. The obtained graphite oxide was sonicated into a graphene oxide solution, and configured to a concentration of 5 mg / ml.

[0031] Step 2: 20mL of graphene oxide colloidal suspension in step 1 and 0.3g of PVA are ultrasonically dissolved and mixed evenly, and 80mL of aqueous solution containing 1.5g of ferrous ion particles is injected under the protection of an inert gas, and 25% ammonia ...

Embodiment 2

[0033] Step 1: Mix 2.0g flake graphite, 46ml concentrated H 2SO 4 Place in a 500ml three-necked flask, and stir evenly in an ice-water mixture at 0°C. Weigh 6.0 g of potassium permanganate, add slowly in batches, and control the temperature of the reaction system at 0-10° C. for 1 h. Then the system was moved into a 35°C water bath and reacted for 3h. After the reaction was finished, 100ml of distilled water was slowly added dropwise and reacted at 90°C for 0.5h. Finally, add 100ml of distilled water and 15ml of H 2 o 2 . The product was washed with 5% HCl and distilled water to pH=6-7. The obtained graphite oxide was sonicated into a graphene oxide solution, and configured to a concentration of 5 mg / ml.

[0034] Step 2: 30mL of graphene oxide colloidal suspension in step 1 and 0.3g of PVA are ultrasonically dissolved and mixed evenly, and 80mL of aqueous solution containing 1.5g of ferrous ion particles is injected under the protection of an inert gas, and 25% ammonia ...

Embodiment 3

[0036] Step 1: Put 2.0g of graphite flakes and 46ml of concentrated nitric acid in a 500ml three-neck flask, and stir evenly in a mixture of ice and water at 0°C. Weigh 6.0 g of potassium perchlorate, add it slowly in batches, and control the temperature of the reaction system at 0-10° C. for 1 h. Then the system was moved into a 35°C water bath and reacted for 3h. After the reaction was finished, 100ml of distilled water was slowly added dropwise and reacted at 90°C for 0.5h. Finally, add 100ml of distilled water and 15ml of H 2 o 2 . The product was washed with 5% HCl and distilled water to pH=6-7. The obtained graphite oxide was sonicated into a graphene oxide solution, and configured to a concentration of 3 mg / ml.

[0037] Step 2: 20mL of graphene oxide colloidal suspension in step 1 and 0.3g of PVA are ultrasonically dissolved and mixed evenly, and 80mL of aqueous solution containing 1.8g of ferrous ion particles is injected under the protection of an inert gas, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com