Percussion hammer

A technology of impact hammer and hammer teeth, which is applied in the field of impact hammers, can solve problems such as hindering hammer teeth hammering and affecting hammering efficiency, and achieve uniform hammering force, stable hammering effect, and guaranteed hammering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

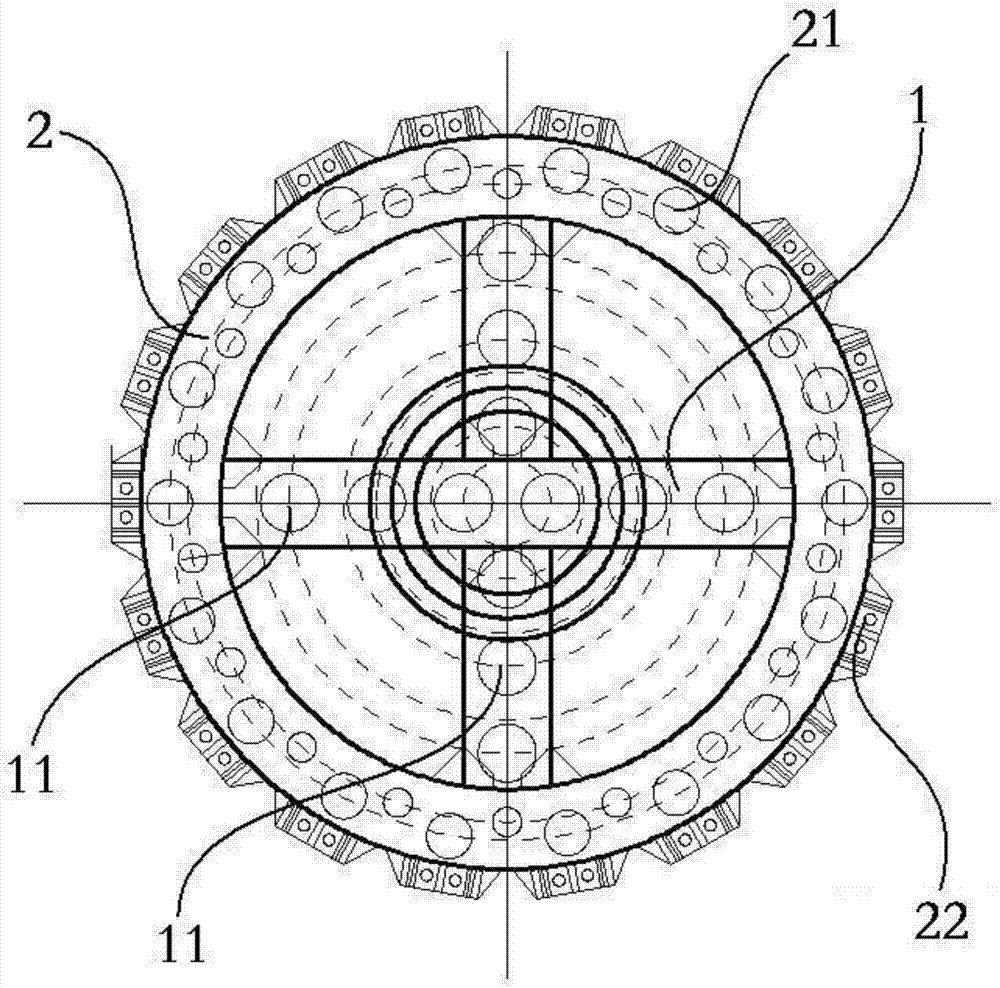

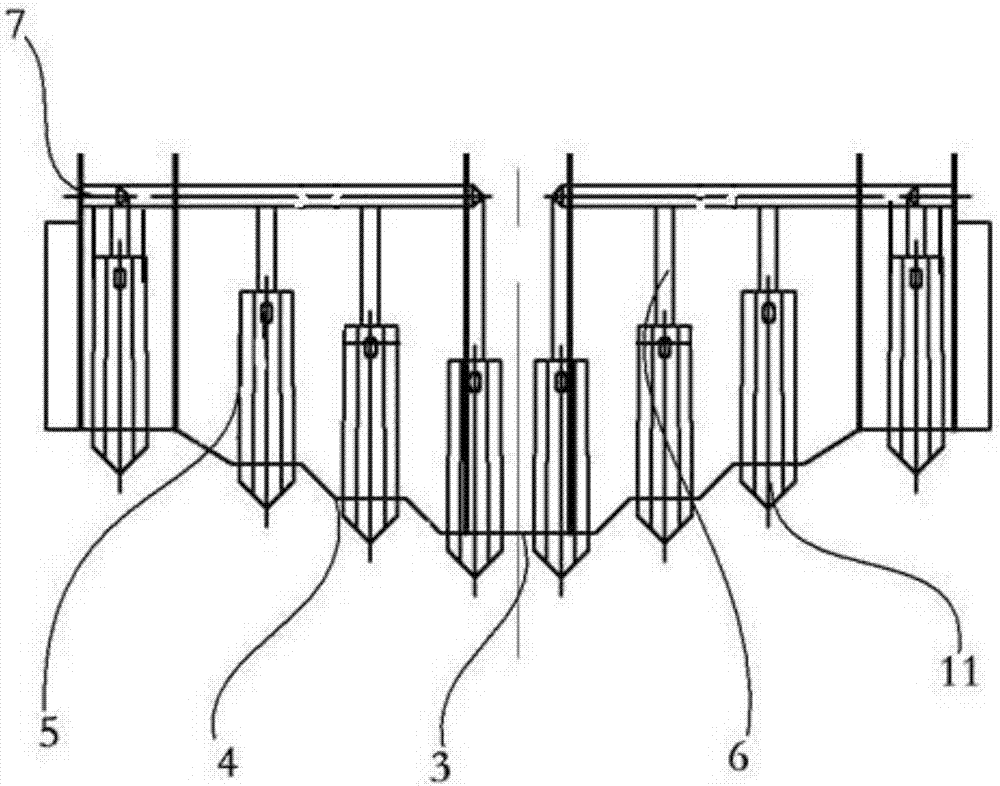

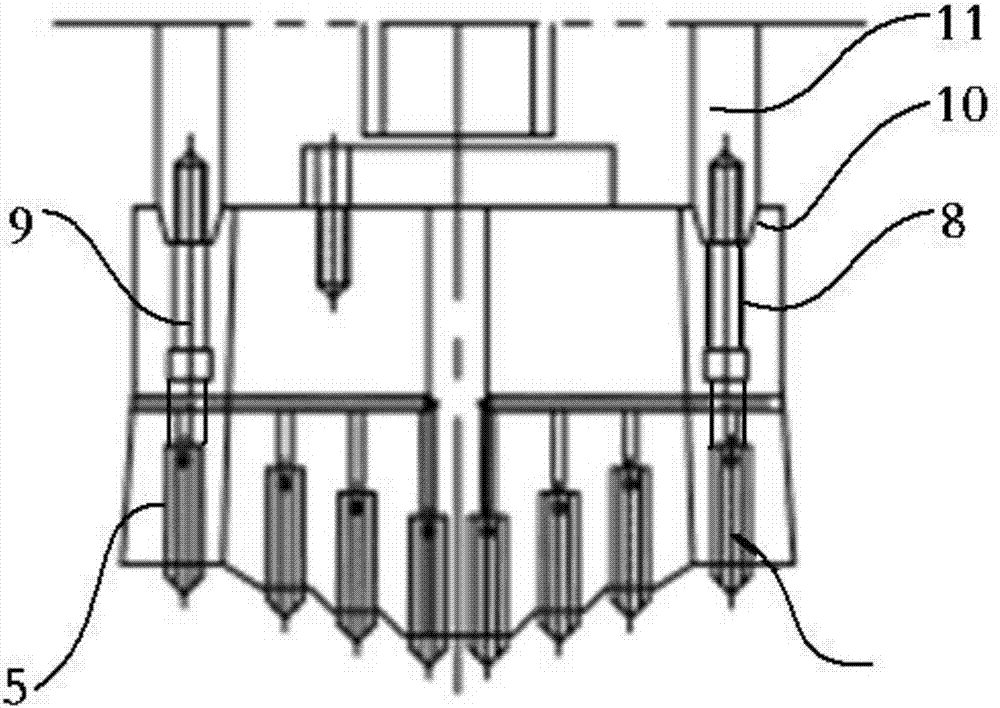

[0047] figure 1 It is a bottom view of the hammer head of the impact hammer provided in the first embodiment of the present invention; figure 2 for figure 1 A longitudinal sectional view of the hammer head shown; image 3 for figure 1 A longitudinal cross-sectional view showing the connection between the hammer body and the hammer head. Such as Figure 1-3 As shown, the impact hammer provided in this embodiment includes a hammer head. The hammer head includes a ring-shaped hammer frame 2 and four hammer beams 1 arranged in the hammer frame 2. The inner ends are fixedly connected to each other at the center of the hammering frame 2, and the outer ends are fixedly connected to the hammering frame 2. The four hammering beams 1 are arranged at equal angular intervals, and each hammering beam 1 is provided with a set of first hammer teeth 11. The first hammer teeth 11 of each group are evenly distributed along the radial direction of the hammer frame 2, and the concentric ring wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com