Hydrate reservoir developing well group structure and method using geothermal energy

A technology of hydrate and geothermal energy, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of large heat loss, low utilization efficiency, high cost, etc., to increase heat exchange efficiency and reduce heat injection Cost, EOR effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings, but the implementation scope of the present invention is not limited.

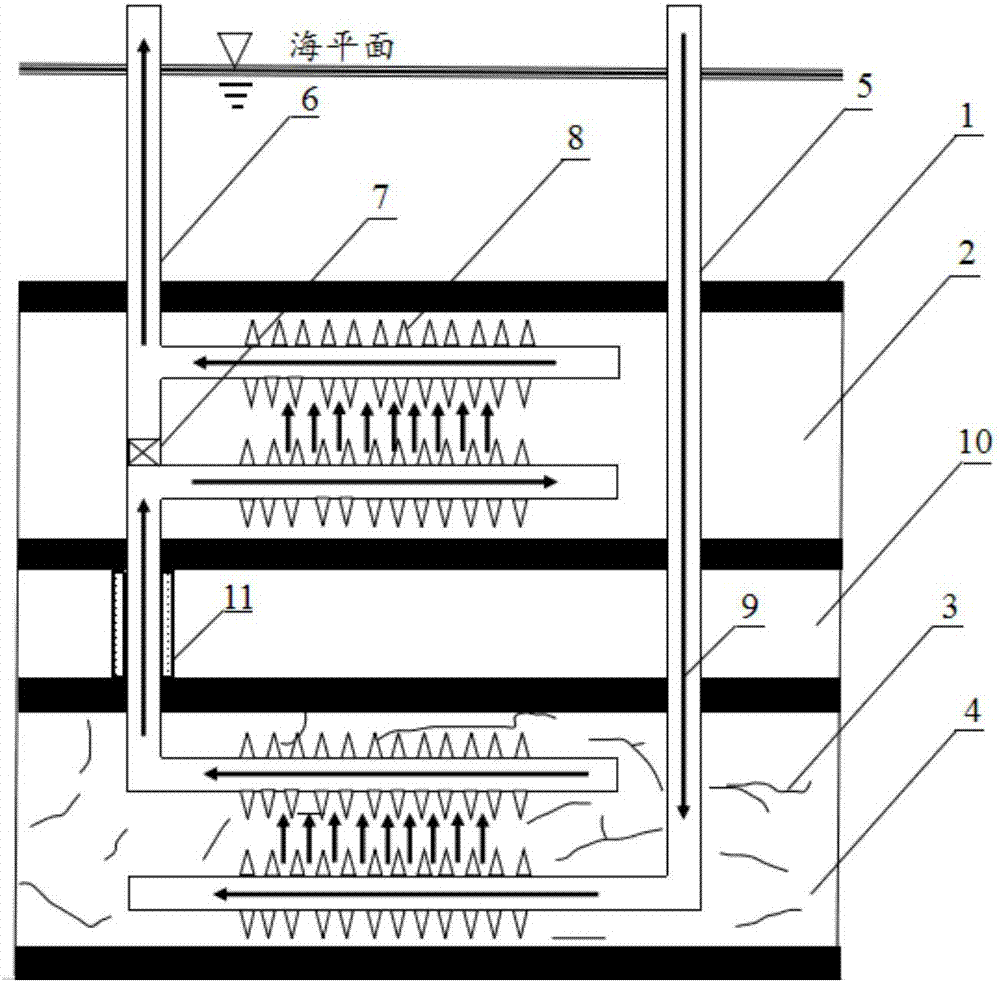

[0016] Such as figure 1 As shown, according to the geological structure conditions, the sea area where hydrate reservoir 2 exists and the hot dry rock reservoir 4 is developed under the hydrate reservoir 2 is selected as the measure area, in which the thickness of hydrate reservoir 2 is 15m, and the The average temperature is 160°C;

[0017] Such as figure 1 As shown, a horizontal injection well 5 and a comprehensive well 6 are drilled at sea level, wherein the horizontal injection well 5 runs through the hydrate reservoir 2 and extends to the lower hot dry rock reservoir 4 A horizontal well section with a length of 800m is generated by building a deflection at the position, and the comprehensive well 6 includes extending from the sea level to the gas hydrate reservoir 2 distance from the top Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com