Flow control valve

A flow control valve and valve port technology, which is applied in the field of flow control valves for adjusting refrigerant flow, can solve the problems of easy occurrence and growth, refrigerant peeling, pressure changes, etc., and achieve smooth flow, reduced pressure loss, and suppressed pressure. effect of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings.

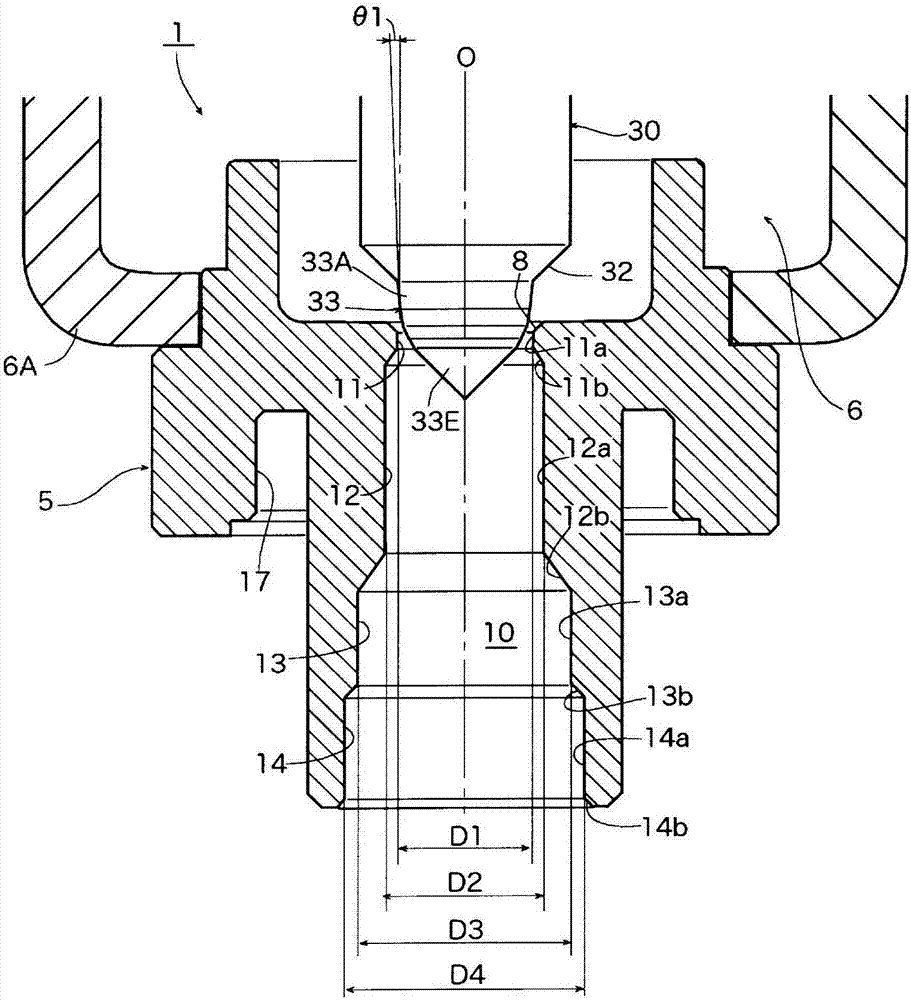

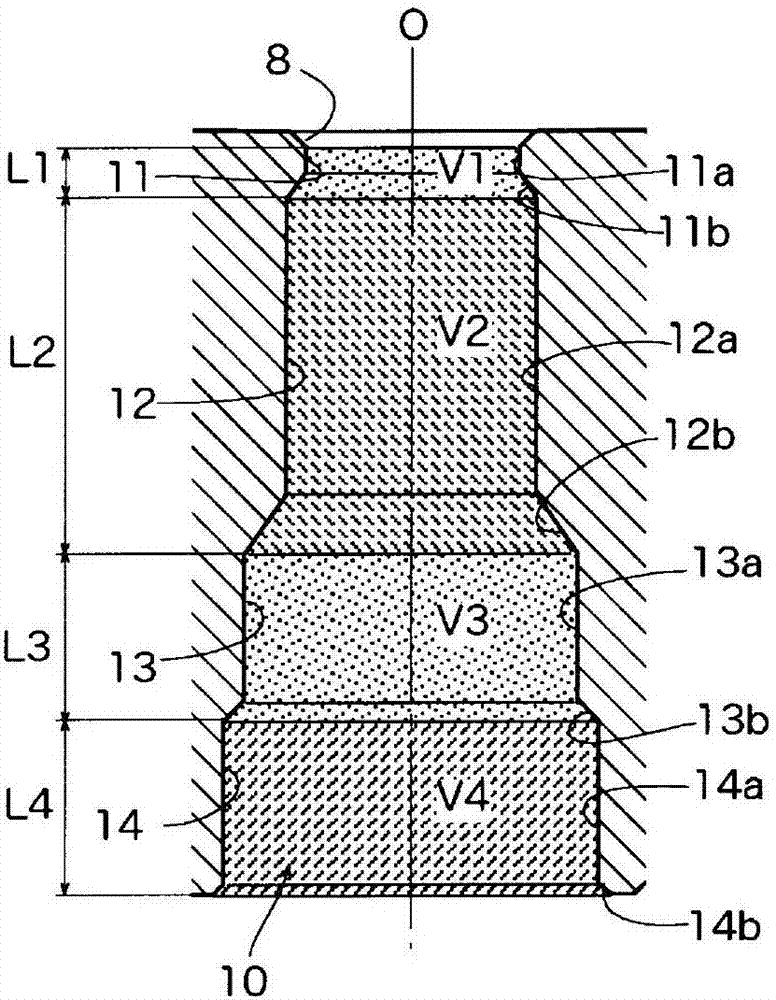

[0036] Figure 1AIt is a cross-sectional view showing an essential part of an embodiment of the flow control valve according to the present invention, Figure 1B is used to describe the composition Figure 1A Diagram of the port length and volume of the 4-stage port portion of the indicated port. In addition, in Figure 1A , Figure 1B , for the above Figure 6A , Figure 6B The parts corresponding to the respective parts of the shown conventional flow regulating valve 3 are given the same reference numerals.

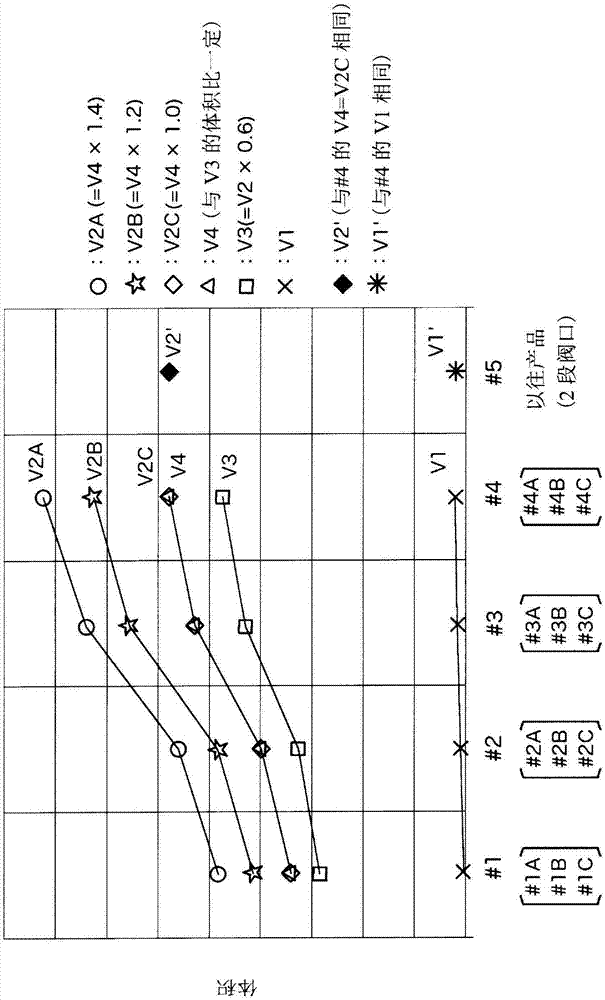

[0037] The flow regulating valve 1 of the illustrated embodiment is the same as the above-mentioned Figure 6A , Figure 6B The conventional flow regulating valve 3 shown is similar to a flow regulating valve used for regulating the flow rate of refrigerant in a heat pump type cooling and heating system, and is formed so as to obtain a characteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com