Winding pipe capable of sealing gap by expanding and mounting method thereof

An installation method and a technology of winding pipes, which are applied in the direction of hoses, pipes, pipe connections, etc., can solve problems such as leakage, and achieve the effect of overcoming deformation stress and reducing the risk of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

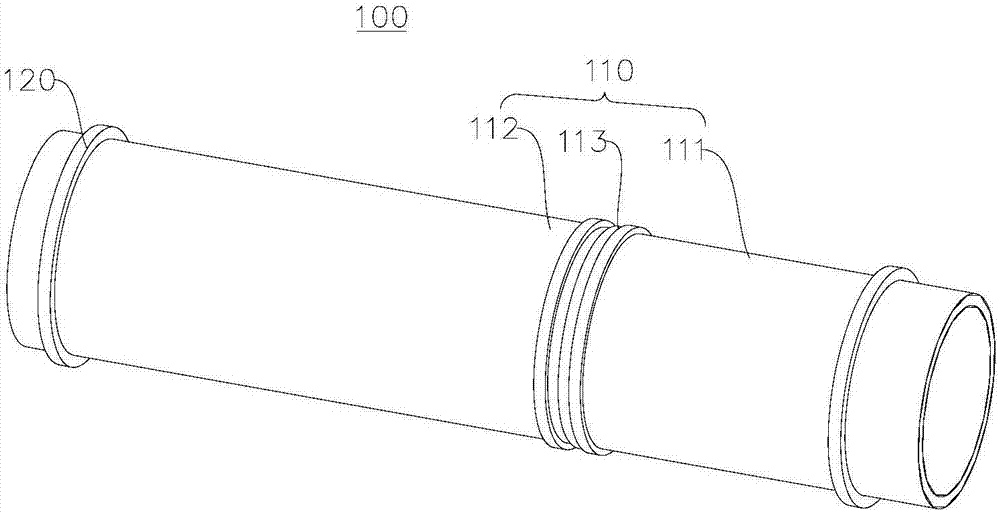

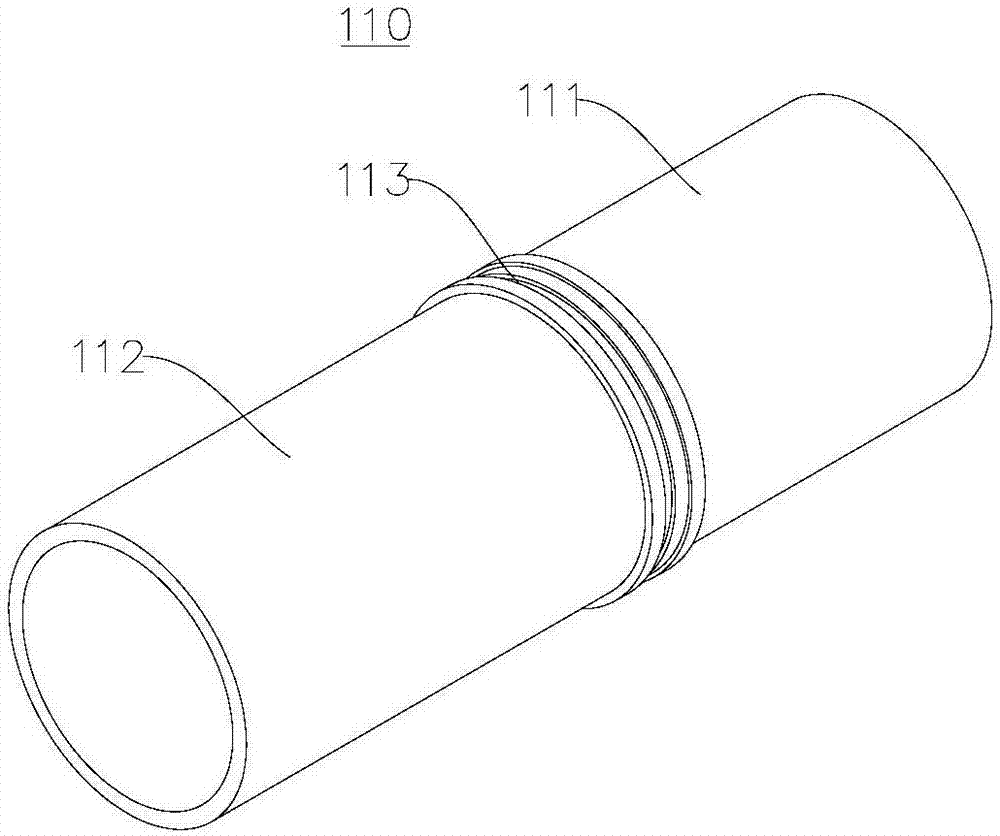

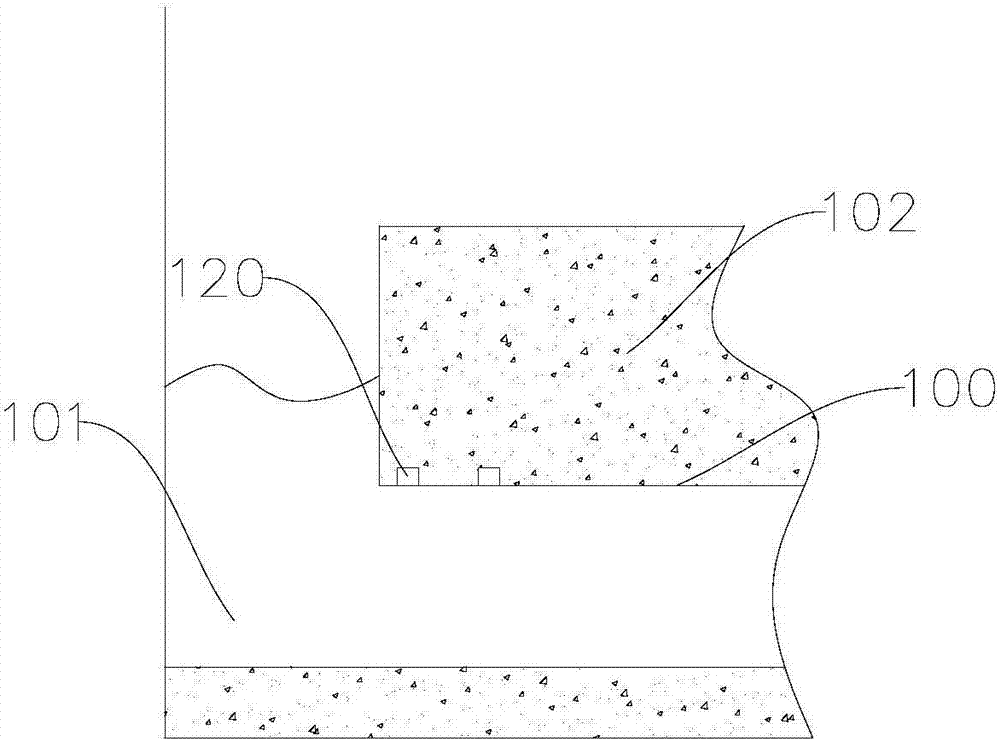

[0035] figure 1 Schematic diagram of the structure of the coiled tube 100 capable of expanding and closing the gap provided by the embodiment of the present invention. figure 2 For the structural schematic diagram of the pipe body 110 provided by the embodiment of the present invention, please refer to figure 1 , figure 2 , the present embodiment provides a winding tube 100 capable of expanding and closing the gap. The winding tube 100 capable of expanding and closing the gap includes a tube body 110 and a rubber strip 120. The rubber strip 120 is arranged outside the tube body 110. The raw material of the rubber strip 120 is The tube body 110 includes a first connecting tube 111 , a second connecting tube 112 , and a telescopic tube 113 , and the first connecting tube 111 is connected to the second connecting tube 112 through the telescopic tube 113 . The telescopic tube 113 can expand and contract along the axial and radial directions of the tube body 110 , and the axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com