Lamp bulb and non-contact type dismantling tool special for lamp bulb

A light bulb and tool technology, applied in the field of non-contact disassembly and assembly tools, can solve the problems of inconvenient operation, hidden dangers of high-altitude operation, low disassembly and assembly efficiency, etc., achieve good technical and use effects, eliminate the risk of electric shock, and simple structural improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

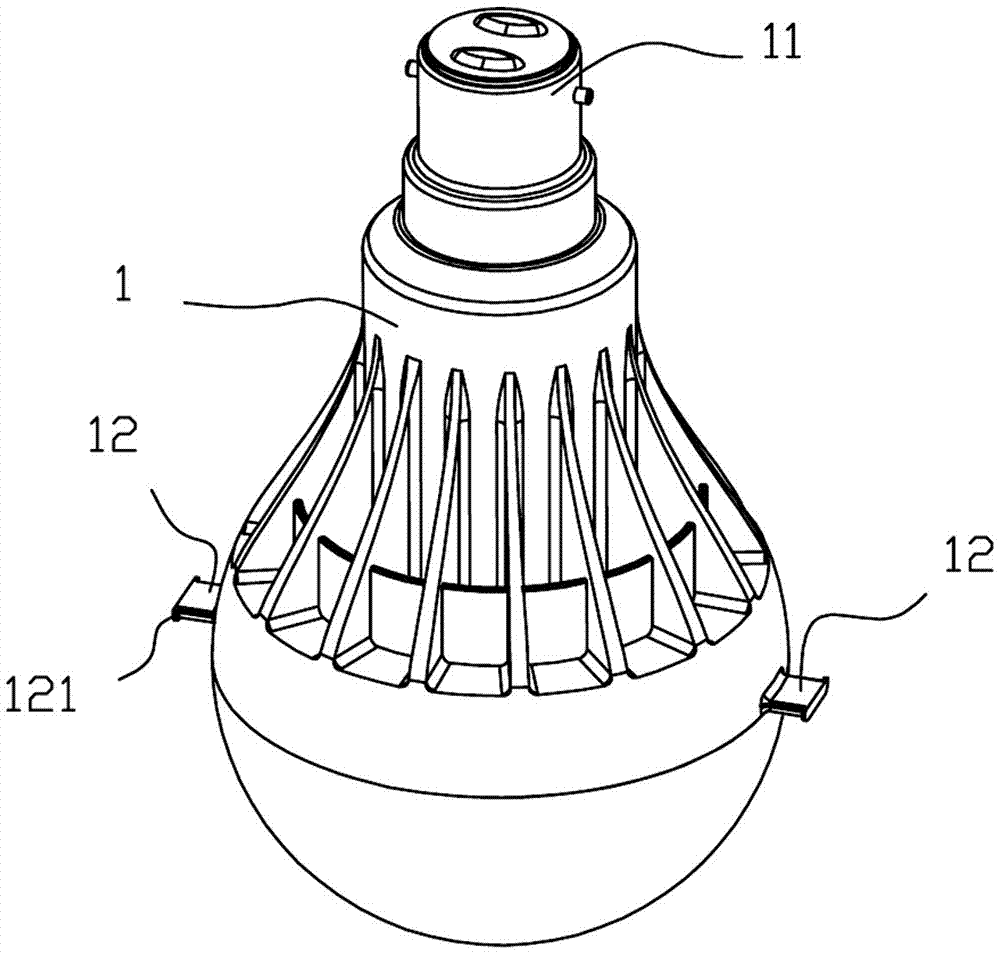

[0046] Such as image 3 As shown, a light bulb that is easy to disassemble and assemble at a long distance includes a light bulb body 1, and a buckle-type joint 11 is provided on the top of the light bulb body 1. In practice, a threaded joint or a plug-in joint can also be used.

[0047] At least one connecting protrusion 12 is provided on the outer circumference of the bulb body 1 . The number of connecting convex strips 12 provided in this illustration is two, but in practice it can be set to one or three or more according to needs.

[0048] The connecting protrusions 12 are arranged at intervals on the bulb body 1 or distributed radially relative to the center of the bulb body 1 . In this figure, the connection protrusions 12 are radially distributed, and in consideration of uniform force, the connection protrusions 12 are evenly spaced along the circumferential direction.

[0049] And as Figure 4 Shown is a structure in which the connecting ribs 12 are arranged.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com