Vapor chamber structure and manufacturing method thereof

A technology of vapor chamber and support structure, which can be applied to structural parts of electrical equipment, cooling/ventilation/heating renovation, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Since the present invention discloses a uniform temperature plate structure, the heat conduction principle used therein has been understood by those with ordinary knowledge in the relevant technical field, so the following description will not be fully described. At the same time, the figures to be compared in the following text express schematic diagrams related to the characteristics of the present invention, and are not drawn completely according to the actual situation and are described first.

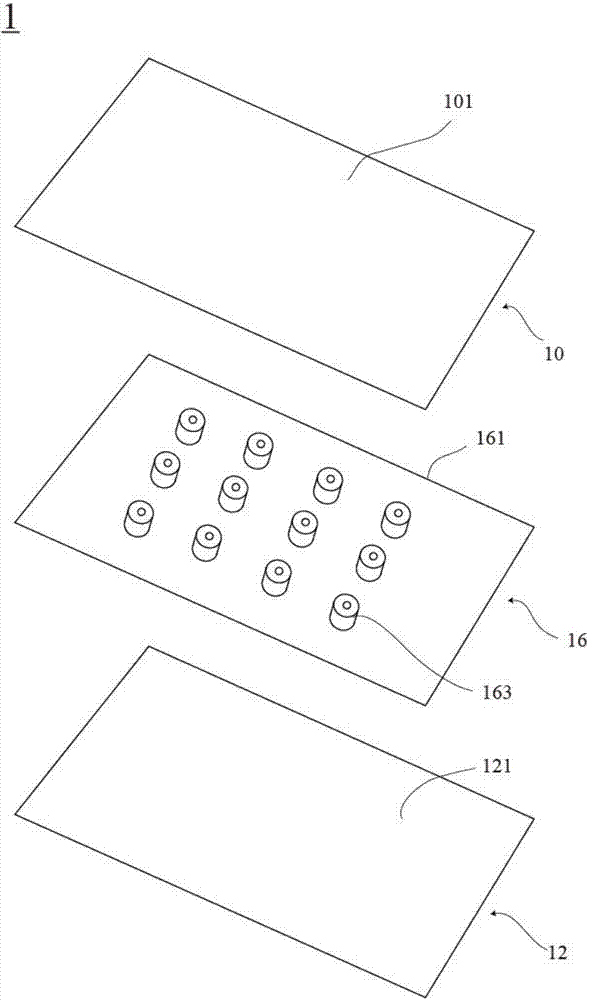

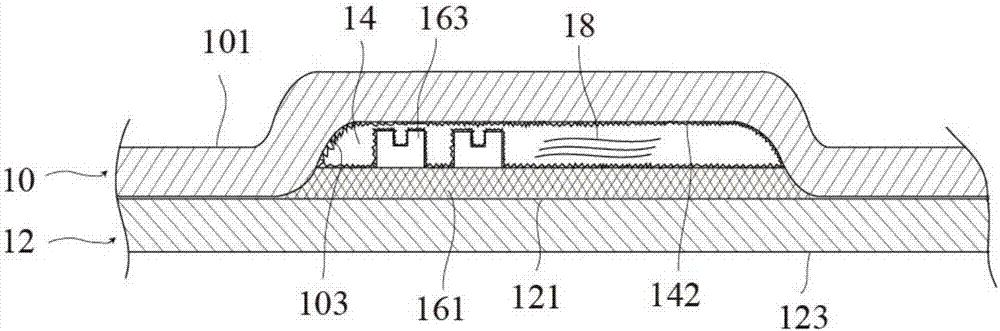

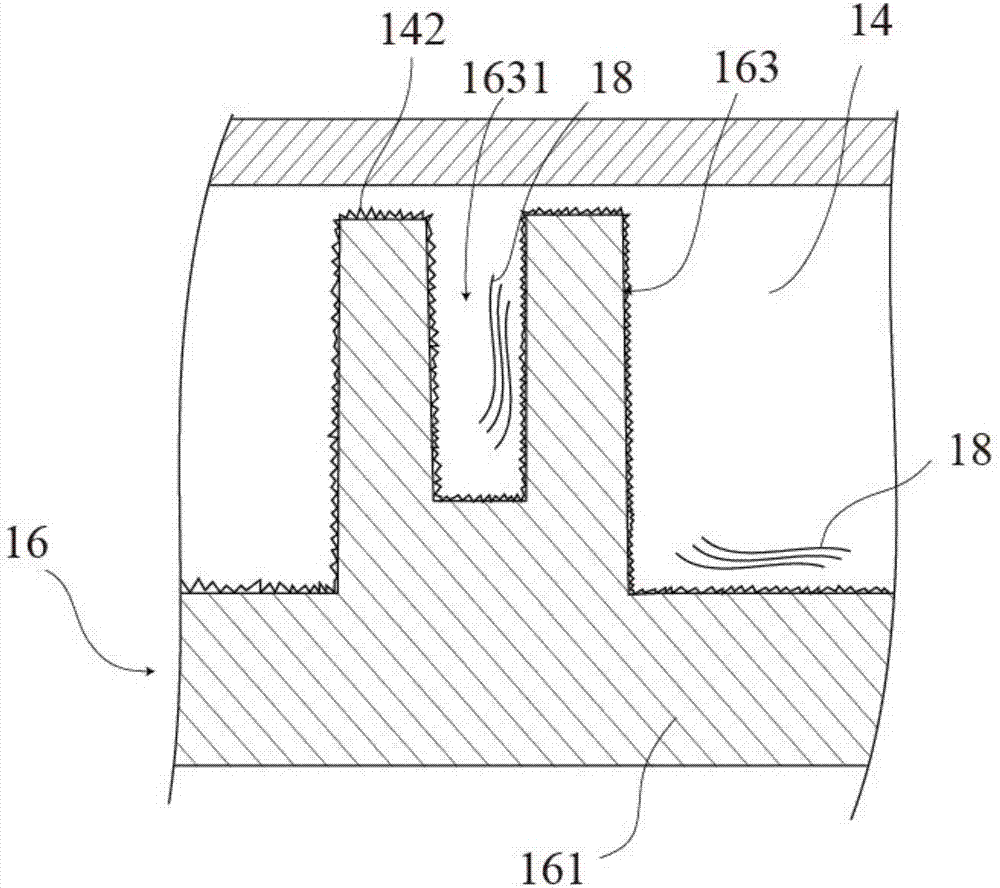

[0050] Please also refer to figure 1 and figure 2 , Are the three-dimensional exploded schematic diagram of the temperature uniform plate structure proposed by the present invention and the three-dimensional cross-sectional schematic diagram of an embodiment. The uniform temperature plate structure 1 includes a first plate 10, a second plate 12, a cavity 14 space, a supporting structure 16 and a working fluid 18. The first plate body 10 has a first surface 101 and an opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com