Stripping of a dip-mouled glove from a former

A technology of gloves and models, applied in the direction of manipulators, manufacturing tools, other household appliances, etc., can solve the problems of difficult to achieve cycle and complex equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

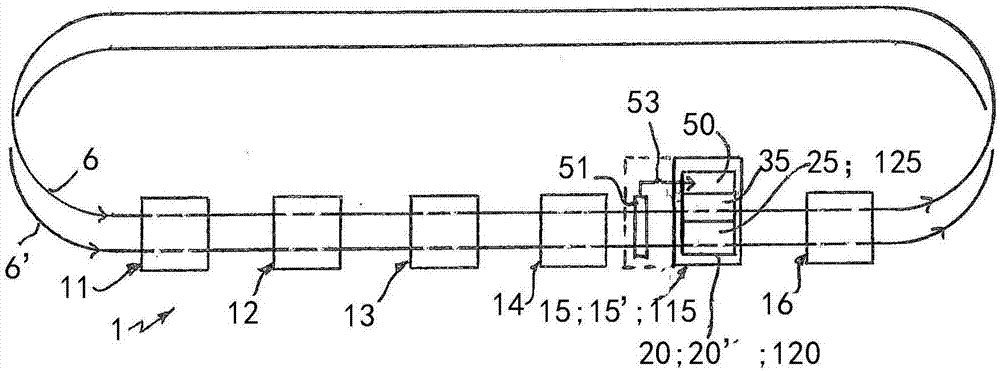

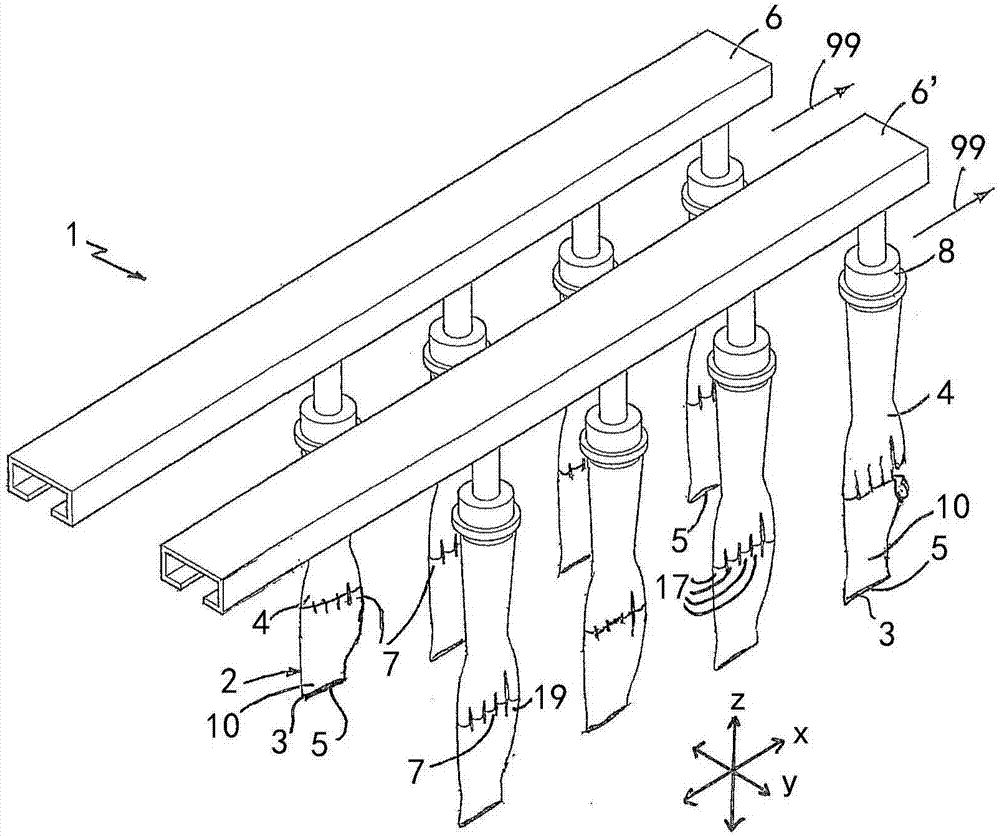

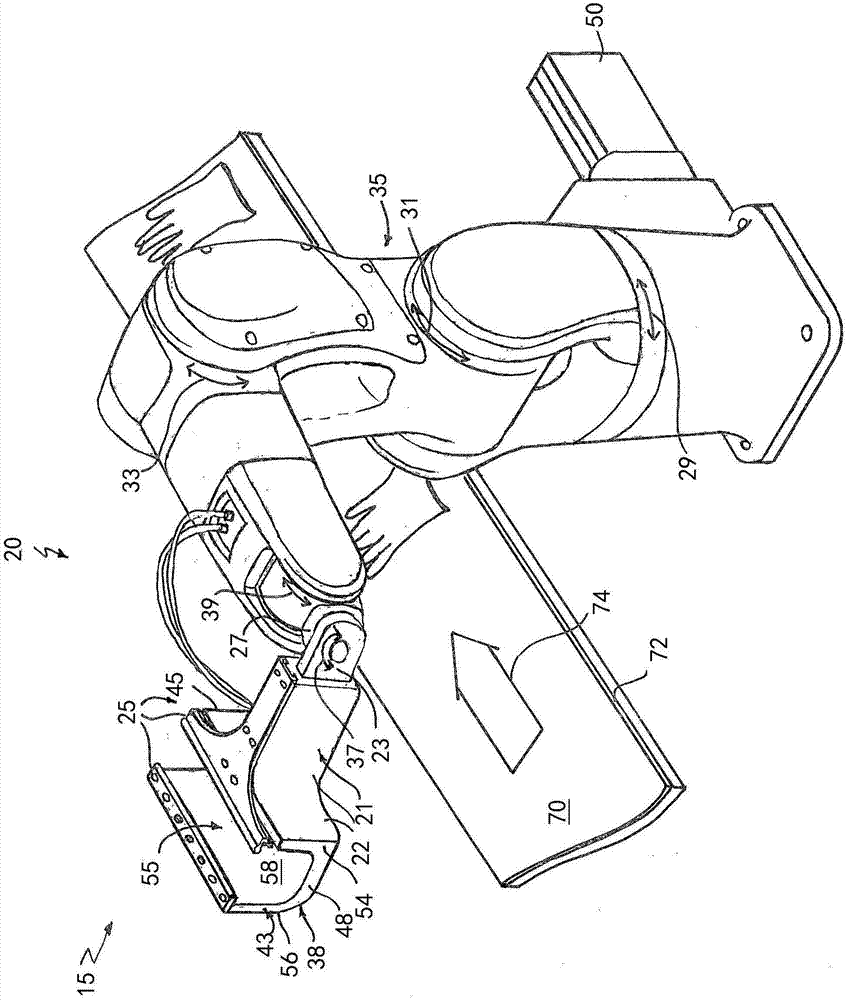

[0114] figure 1 shows a schematic diagram of production line 1, while figure 2 A perspective view of a section of a production line used in various embodiments of the invention described in detail below is shown. The production line has conveying equipment, in this example a pair of rail conveyors 6, 6' which convey a series of downwardly depending dip-molding forms 4 on which the gloves 2 have been cast. Dip molding and subsequent curing. In this example, the models are spaced on 200mm centers.

[0115] Gloves are made of elastic material, and in this example are disposable nitrile exam gloves for medical, dental, veterinary or food preparation applications, however, the principles of the invention are applicable to similar materials made of thin and flexible elastic Other types of dipped molded gloves made and having rolled ends. The glove is formed on the dip molded form 4 using production techniques familiar to those skilled in the art. In this example, there are two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com