Release film

A technology of release film and mold layer, which is applied in the direction of film/sheet release liner, film/sheet without carrier, film/sheet adhesive, etc., which can solve the problem of contamination of bonding process and deterioration of transferability , Contamination of adhesives and other issues, to achieve the effect of low transferability, good mold release and high value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

[0022] The polyester film in the present invention refers to a film obtained by stretching a sheet melt-extruded from an extrusion port by a so-called extrusion method.

[0023] The polyester constituting the above-mentioned film refers to a polymer containing an ester bond obtained by polycondensation of dicarboxylic acid and diol or hydroxycarboxylic acid. Examples of the dicarboxylic acid include terephthalic acid, isophthalic acid, adipic acid, azelaic acid, sebacic acid, 2,6-naphthalene dicarboxylic acid, 1,4-cyclohexanedicarboxylic acid, and the like; Examples of diols include ethylene glycol, 1,4-butanediol, diethylene glycol, triethylene glycol, pentaerythiol, 1,4-cyclohexanedimethanol, polyethylene glycol, Diol and the like; As the hydroxycarboxylic acid, p-hydroxybenzoic acid, 6-hydroxy-2-naphthoic acid and the like can be exemplified. Typical examples of such polymers include polyethylene terephthalate, polyethylene 2,6-naphthalate, and the like.

[0024] The film...

no. 2 approach >

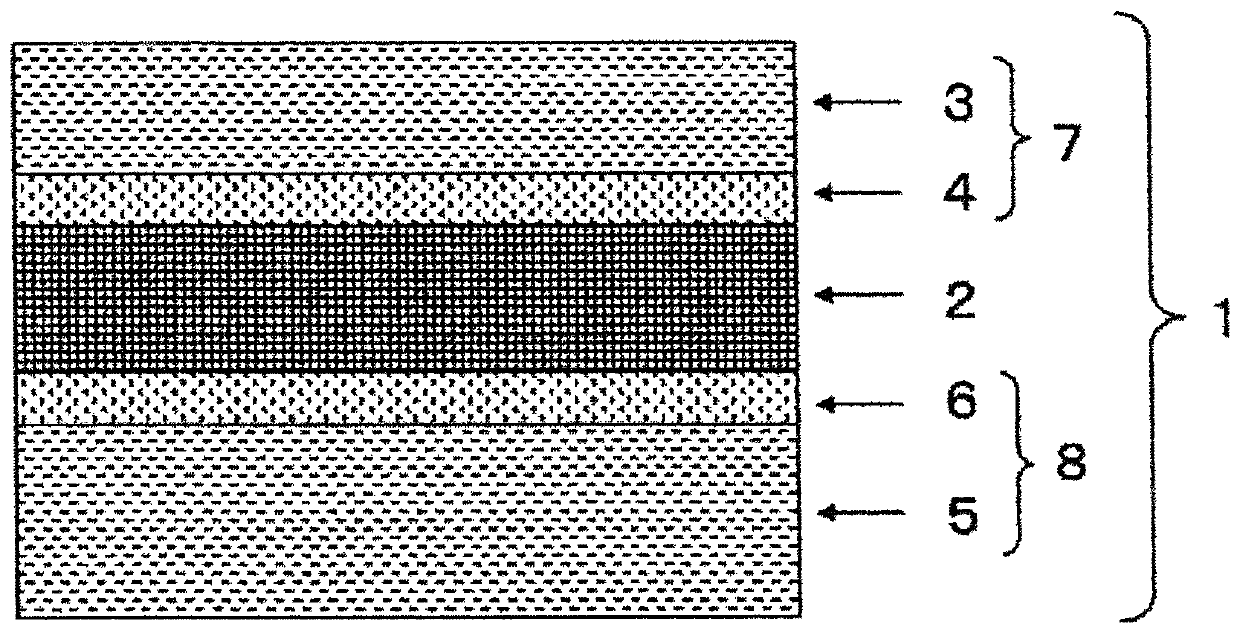

[0090] In the present invention, the polyester film constituting the two types of release films (hereinafter, the one with the smaller release force may be referred to as the first release film, and the one with the larger release force may be referred to as the second release film) may be a single The layer structure may be a laminated structure, for example, in addition to the 2-layer or 3-layer structure, it may also be a multilayer of 4 or more layers within the limit not exceeding the gist of the present invention, and is not particularly limited.

[0091] The polyester used for the polyester film in the present invention may be homopolyester or copolyester. When composed of a homopolyester, a polyester obtained by polycondensation of an aromatic dicarboxylic acid and an aliphatic diol is preferable.

[0092] Examples of aromatic dicarboxylic acids include terephthalic acid and 2,6-naphthalene dicarboxylic acid, and examples of aliphatic diols include ethylene glycol, die...

Embodiment 1-1

[0298]

[0299] The above-mentioned polyester (1) was supplied as a raw material to an extruder with a vent, and after being melt-extruded at 290°C, it was solidified by cooling on a cooling roll whose surface temperature was set at 40°C by electrostatic application encryption. , an amorphous film with a thickness of about 550 μm was obtained.

[0300] This film was stretched 3.7 times in the longitudinal direction at 85° C., stretched 3.9 times in the transverse direction at 100° C., and heat-treated at 210° C. to obtain a biaxially stretched polyester film with a thickness of 38 μm.

[0301] On the obtained polyester film, a release agent including the release agent composition-A shown below was applied in an amount (after drying) of 0.12 g / m 2 The coating method was carried out by reverse gravure coating, and a roll-shaped release polyester film was obtained under the conditions of a dryer temperature of 150°C and a line speed of 30 m / min.

[0302]

[0303] a1: the cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com