Acrylic rubber composition

An acrylic rubber and composition technology, which is applied in shock absorbers, jet propulsion devices, transportation and packaging, etc., can solve the problems of easy reduction of tanδ and damage to the anti-vibration effect, and achieves excellent tanδ value and improved anti-vibration performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

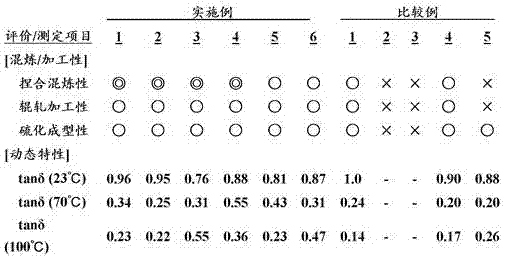

Examples

Embodiment 1

[0040] Acrylic rubber containing active chlorine groups 100 parts by weight

[0041] (UNIMATEC product Noxtite PA401-L)

[0042] Styrene acrylic resin containing epoxy group 20 parts by weight

[0043] (East Asia synthetic products ARUFON UG-4040)

[0044] Sulfur 0.2 parts by weight

[0045] These were kneaded with a pressurized kneader, followed by roll processing with an open roll, and after vulcanization at 190°C for 8 minutes, oven vulcanization (secondary vulcanization) at 175°C for 5 hours to form a thickness of 2mm of flakes.

[0046] Kneading properties, roll workability, and vulcanization formability were evaluated, and dynamic properties (tan δ) were measured.

[0047] Mixability:

[0048] (1) When kneading with a pressurized kneader, no bridge (rubber block) is formed in the gap between the rotor and the weight, and the kneading process is carried out stably

[0049] (2) There is no pollution in the mixer after the blank is discharged

[0050] In (1) and (2),...

Embodiment 2

[0064] In Example 1, instead of the epoxy group-containing styrene acrylic resin, the same amount of hydroxyl group-containing styrene acrylic resin (Toagosei ARUFON UH-2170) was used.

Embodiment 3

[0066] In Example 1, the amount of the epoxy group-containing styrene acrylic resin was changed to 40 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com