Acrylic rubber composition

一种丙烯酸橡胶、组合物的技术,应用在减震器、喷气推进装置、运输和包装等方向,能够解决tanδ易降低、防振效果受损等问题,达到tanδ值优异、防振性提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

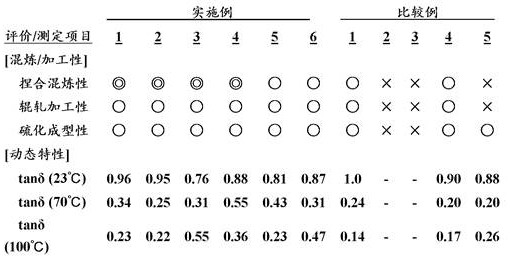

Examples

Embodiment 1

[0040] Acrylic rubber containing active chlorine groups 100 parts by weight

[0041] (UNIMATEC product Noxtite PA401-L)

[0042] Styrene acrylic resin containing epoxy group 20 parts by weight

[0043] (East Asia synthetic products ARUFON UG-4040)

[0044] Sulfur 0.2 parts by weight

[0045] These were kneaded with a pressurized kneader, followed by roll processing with an open roll, and after vulcanization at 190°C for 8 minutes, oven vulcanization (secondary vulcanization) at 175°C for 5 hours to form a thickness of 2mm of flakes.

[0046] Kneading properties, roll workability, and vulcanization formability were evaluated, and dynamic properties (tan δ) were measured.

[0047] Mixability:

[0048] (1) When kneading with a pressurized kneader, no bridge (rubber block) is formed in the gap between the rotor and the weight, and the kneading process is carried out stably

[0049] (2) There is no pollution in the mixer after the blank is discharged

[0050] In (1) and (2),...

Embodiment 2

[0064] In Example 1, instead of the epoxy group-containing styrene acrylic resin, the same amount of hydroxyl group-containing styrene acrylic resin (Toagosei ARUFON UH-2170) was used.

Embodiment 3

[0066] In Example 1, the amount of the epoxy group-containing styrene acrylic resin was changed to 40 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com