Resin composition and optical lens

A technology of resin composition and resin, applied in optics, lenses, optical elements, etc., can solve the problems of heat resistance (insufficient glass transition temperature, miscibility (low compatibility, unable to measure Abbe number, etc.), To achieve the effect of broadening the design freedom, high compatibility and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

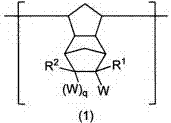

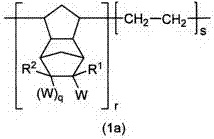

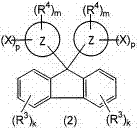

Method used

Image

Examples

Embodiment 1

[0143] 85 parts by weight of pellets of "ARTON" (manufactured by JSR Co., Ltd., F4520, Tg=164°C, Mw=60000) as a cyclic olefin resin, and 9,9-bis(4-(2 -Hydroxyethoxy) phenyl) fluorene (manufactured by Osaka Gas Chemical Co., Ltd., hereinafter referred to as BPEF) 15 parts by weight is kneaded using a twin-screw extruder (manufactured by Technobell, model KZW15 / 45), extruded The strand material was discharged and cut with a cutter to obtain pellets. The appearance of the resin composition was a colorless and transparent pellet.

Embodiment 2

[0145] Except having used 90 weight part of cyclic olefin resins and 10 weight part of BPEF, it carried out similarly to Example 1, and obtained the resin composition.

Embodiment 3

[0147] Except having used 95 weight part of cyclic olefin resins and 5 weight part of BPEF, it carried out similarly to Example 1, and obtained the resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com