Apparatus for subjecting a substrate surface to a continuous surface reaction

A substrate and precursor technology, applied in coating, gaseous chemical plating, metal material coating process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

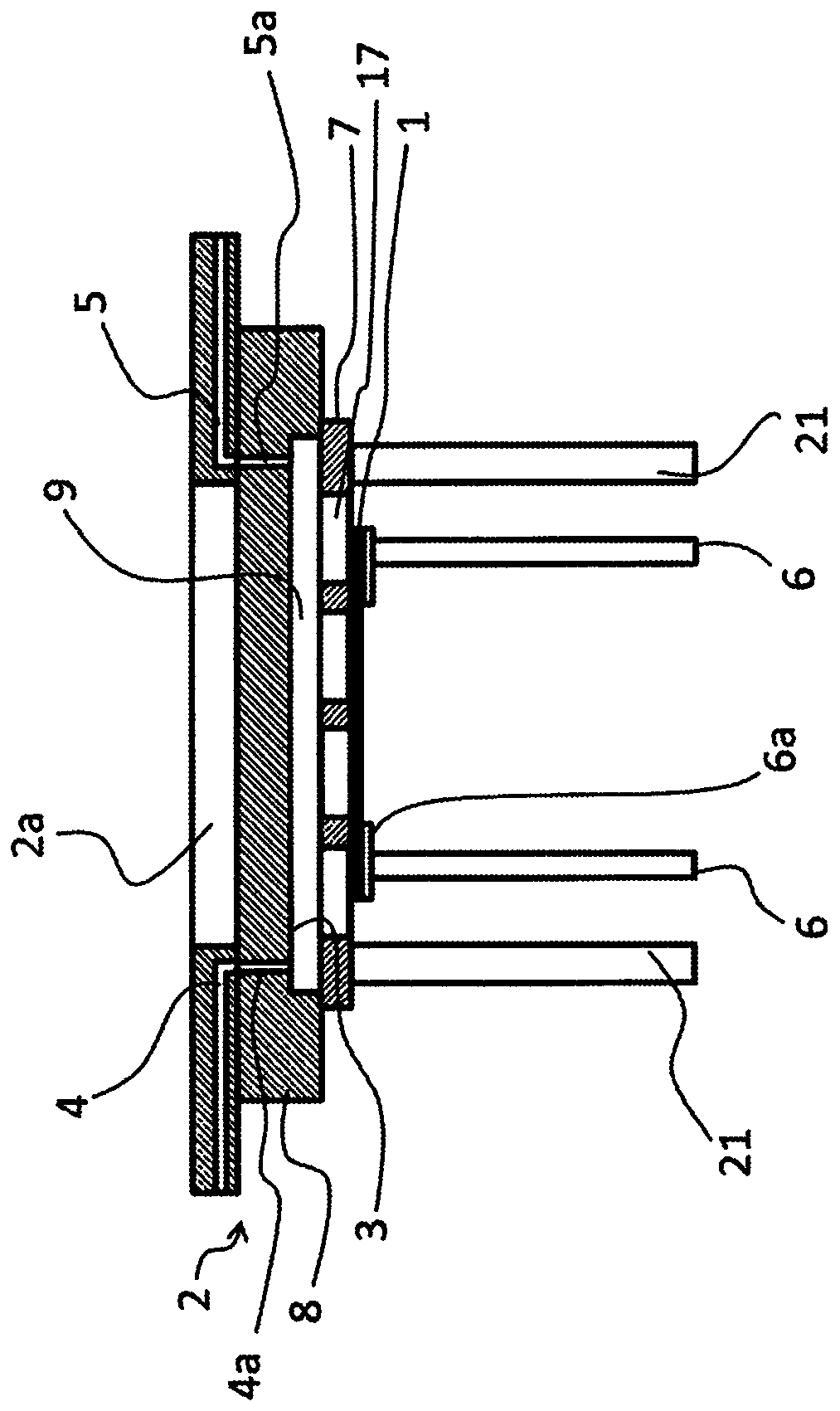

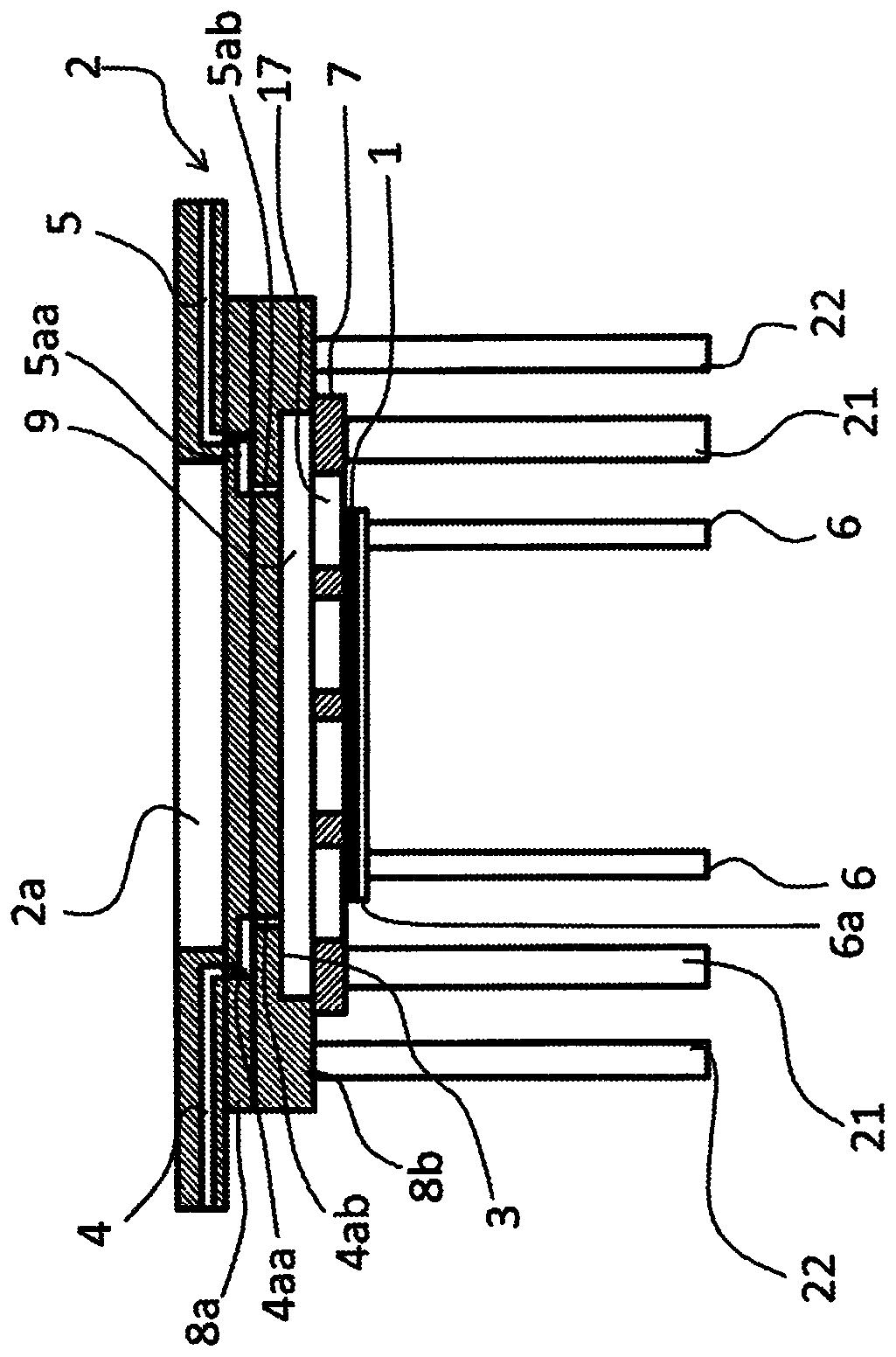

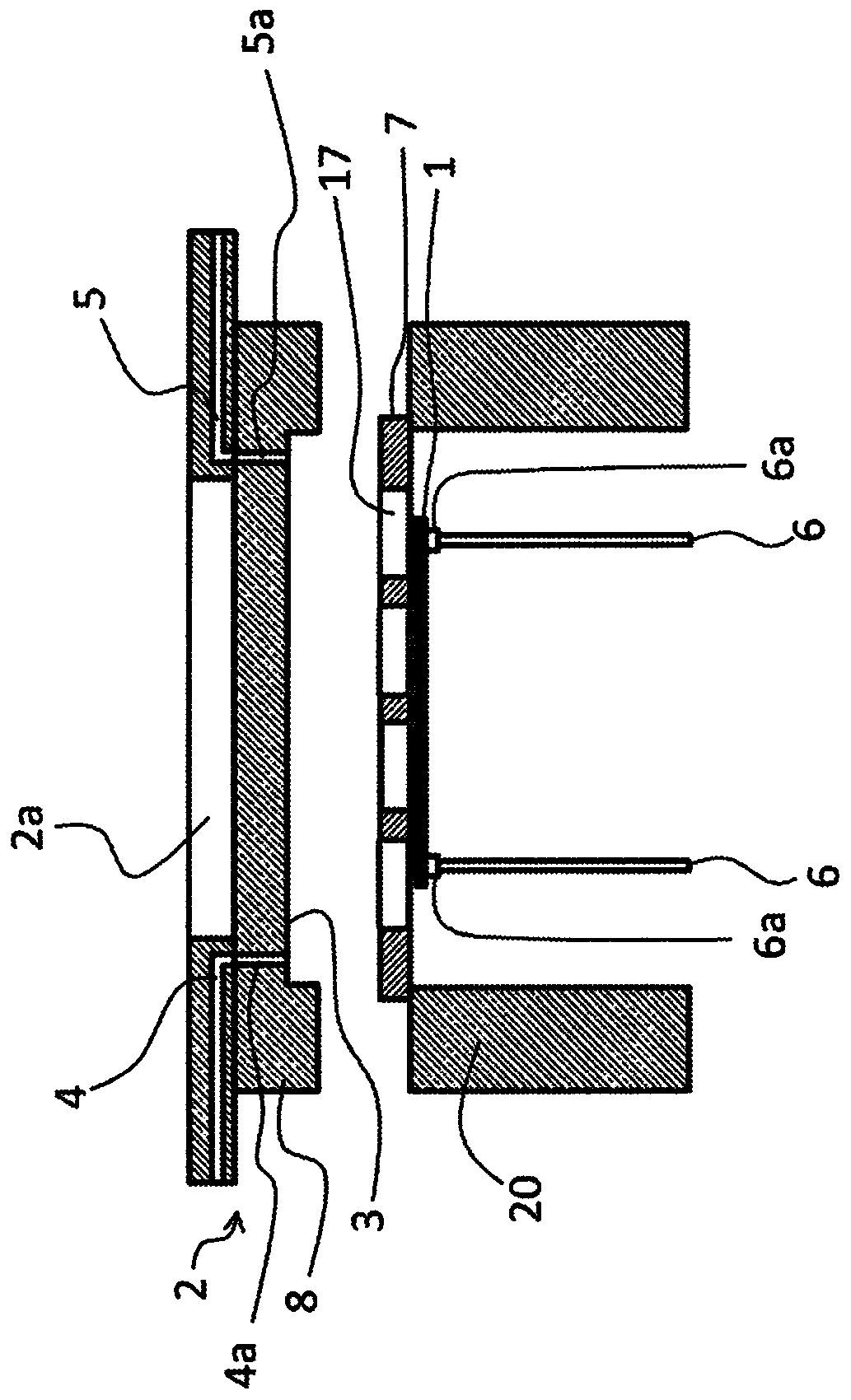

[0023] figure 1 An apparatus according to the invention is shown comprising a gas manifold 2 for supplying precursor material to the surface of a substrate 1 . The gas manifold 2 comprises an output face 3 , at least one precursor supply channel 4 for supplying precursors to the surface of the substrate 1 and at least one exhaust channel 5 for exhausting precursors from the surface of the substrate 1 . The precursors are supplied and discharged through the output face 3 . The device also comprises a substrate holder 6 for moving said substrate 1 in vertical direction. The substrate holder 6 is movable in the vertical direction for moving the substrate 1 between the process position and the loading position. The process position is the position of the substrate 1 during substrate coating, ie when the precursors are supplied on the surface of the substrate 1 . This means that in the process position the surface of the substrate 1 is in fluid connection with the output face 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com