Electric vacuum cleaner

A vacuum cleaner, electric technology, applied in the direction of vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problems of blockage of filter surface, difficulty in forming a tight state of dust collection chamber, low dust collection power, etc., to achieve the effect of maintaining dust collection power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0025] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, the present invention is not limited by this embodiment.

[0026] use Figure 1A ~ Figure 6B , the electric vacuum cleaner in Embodiment 1 of the present invention will be described.

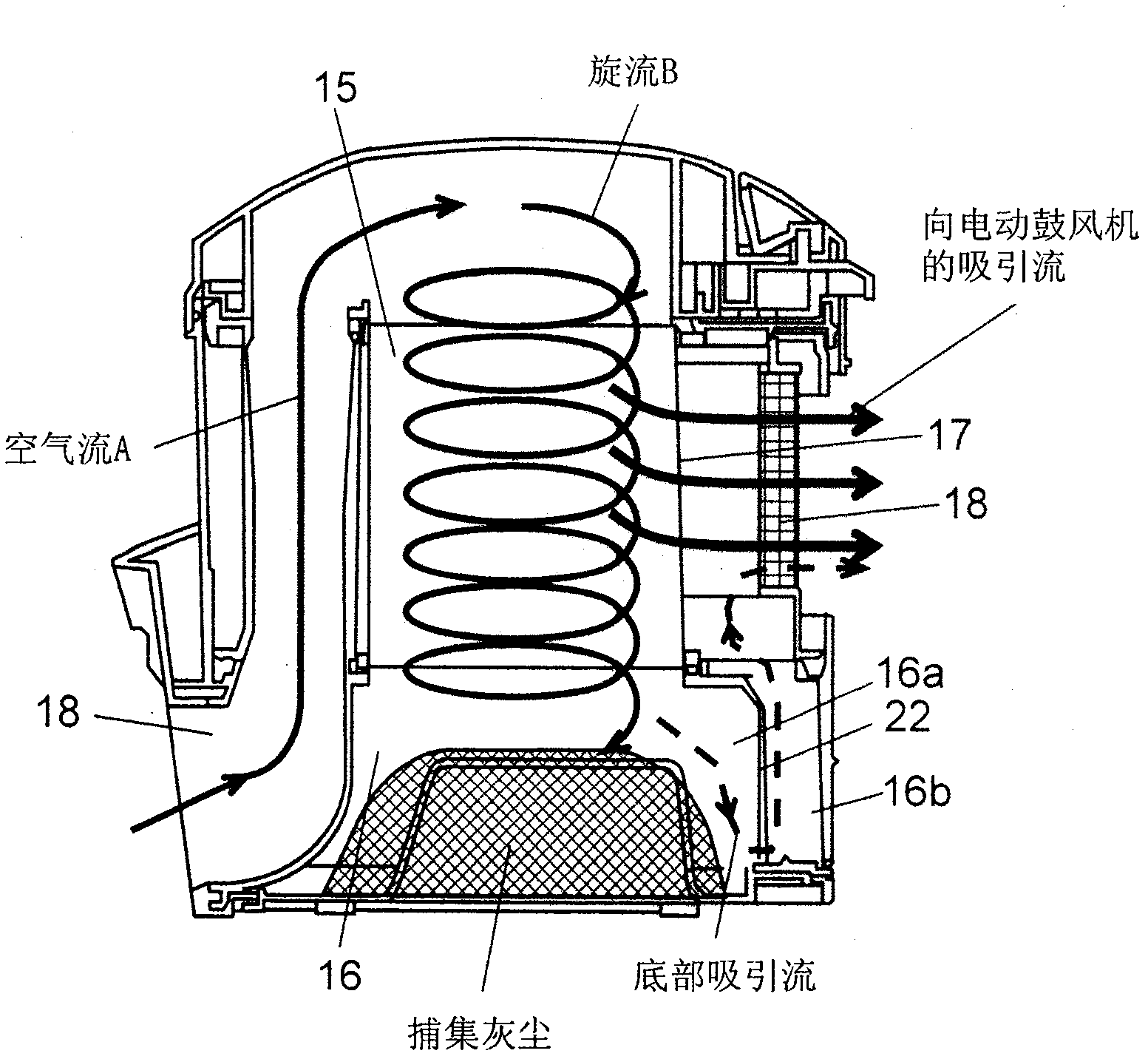

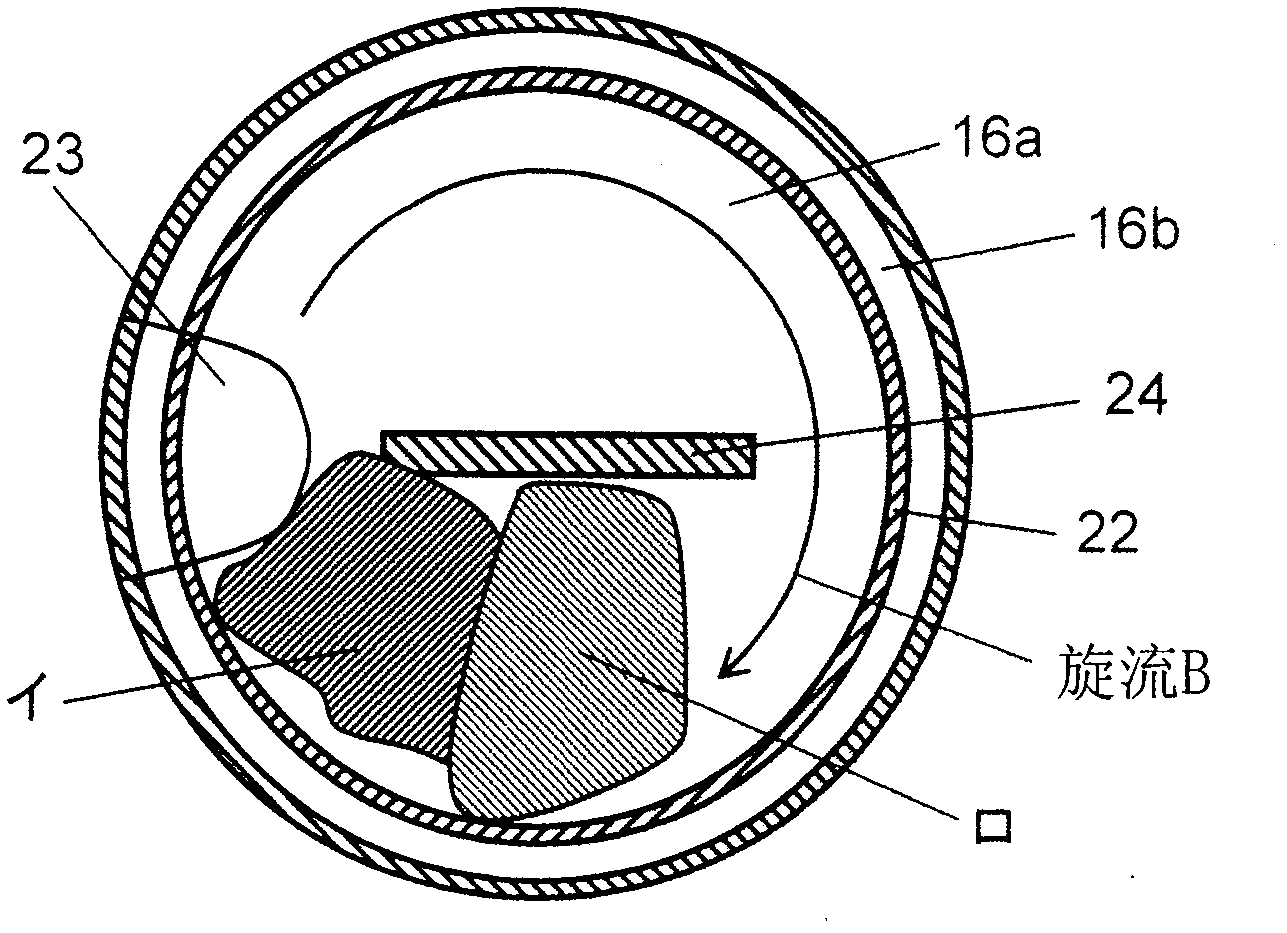

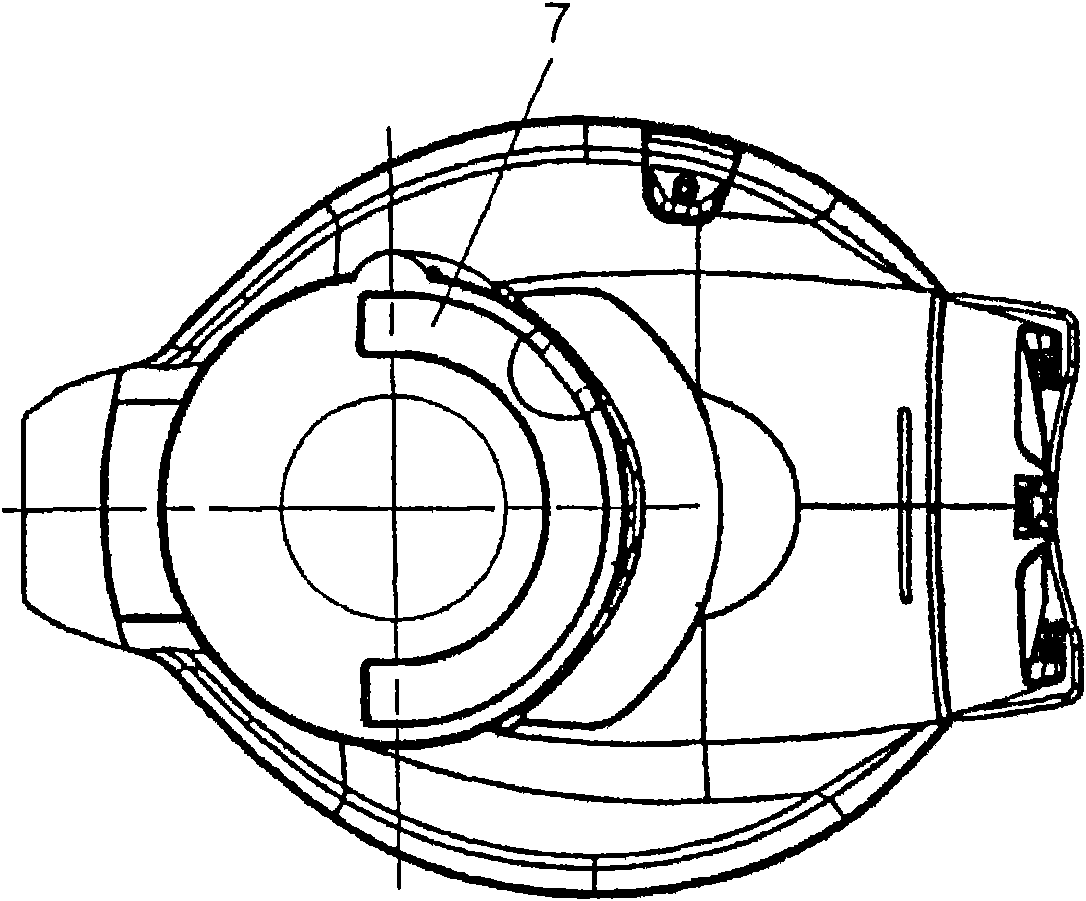

[0027] Figure 1A , Figure 1B It is a plan view and a side view of the electric vacuum cleaner main body in Embodiment 1. figure 2 It is a central sectional view of the electric vacuum cleaner main body in Embodiment 1. Figure 3A , Figure 3B It is a central sectional view and detailed views of each part of the dust box which is the characteristic of the present invention. Figure 4 is the plan view of the swirl chamber. Figure 5A , Figure 5B It is a schematic sectional view of the dust box and a sectional view of the dust chamber viewed from the direction of the motor. Figure 6A , Figure 6B It is a cross-sectional view and a plan view showing a structure in whi...

Embodiment approach 2

[0043] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, this invention is not limited to this embodiment.

[0044] use Figure 7A ~ Figure 9 , the electric vacuum cleaner according to Embodiment 2 of the present invention will be described.

[0045] Figure 7A , Figure 7BIt is a central sectional view and partial detailed view of the dust box in Embodiment 2. Figure 8 It is a perspective view of main parts when the bottom cover is opened in the dust box in Embodiment 2. Figure 9 It is a schematic diagram showing the structure that collects dust in the dust box. In addition, the same symbols as in Embodiment 1 have the same structure, and description thereof will be omitted.

[0046] In Embodiment 2, the lower end portion of the separation wall 22 is divided into two separation walls to form a double wall, the inner side is a comb-shaped separation wall 20 that forms a comb-like concavo-convex, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com