Vortex fluid machinery

A fluid machinery and vortex technology, which is used in rotary piston machinery, mechanical equipment, liquid fuel engines, etc., can solve problems such as volume imbalance and efficiency drop, and achieve the effect of eliminating mixing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

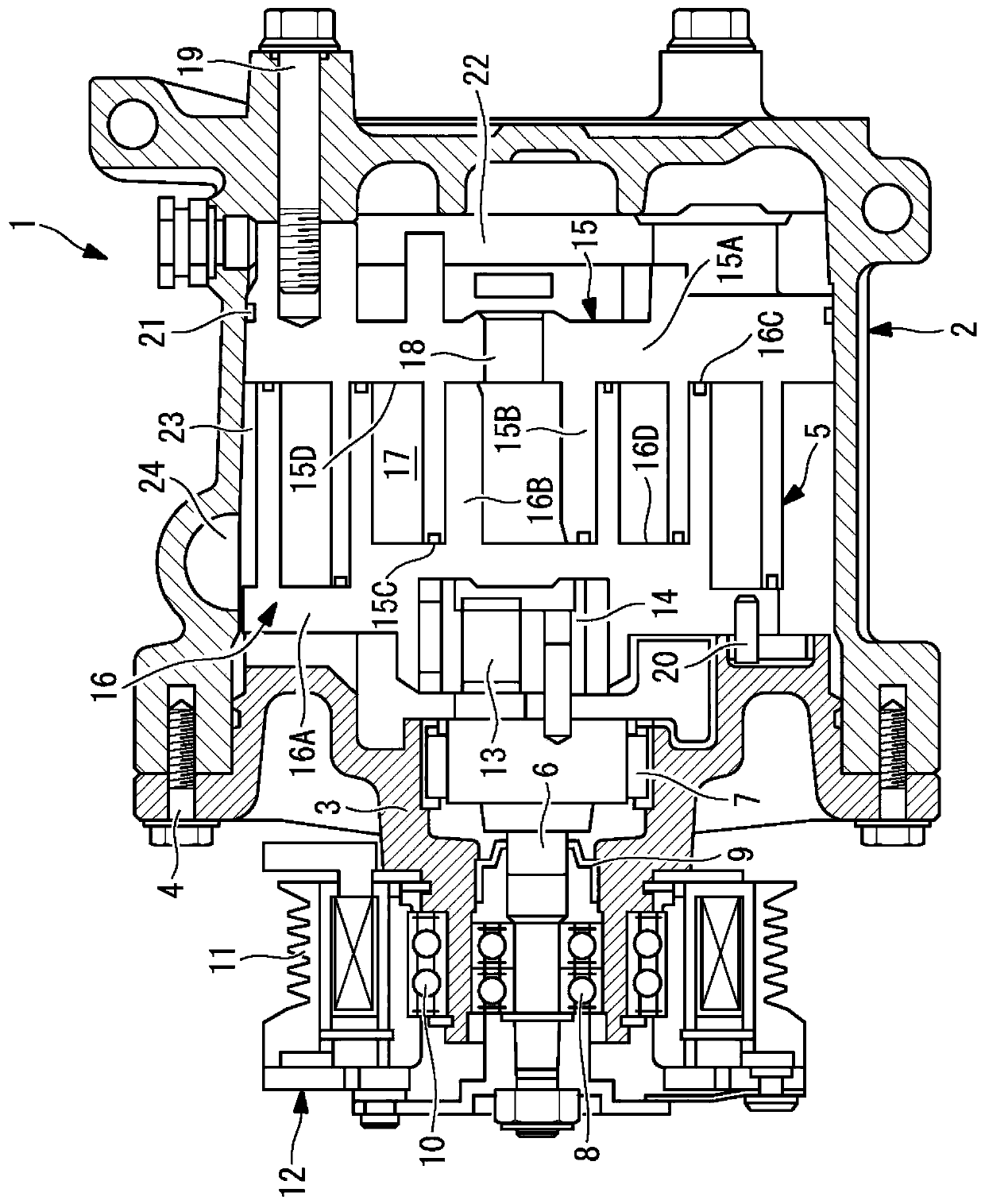

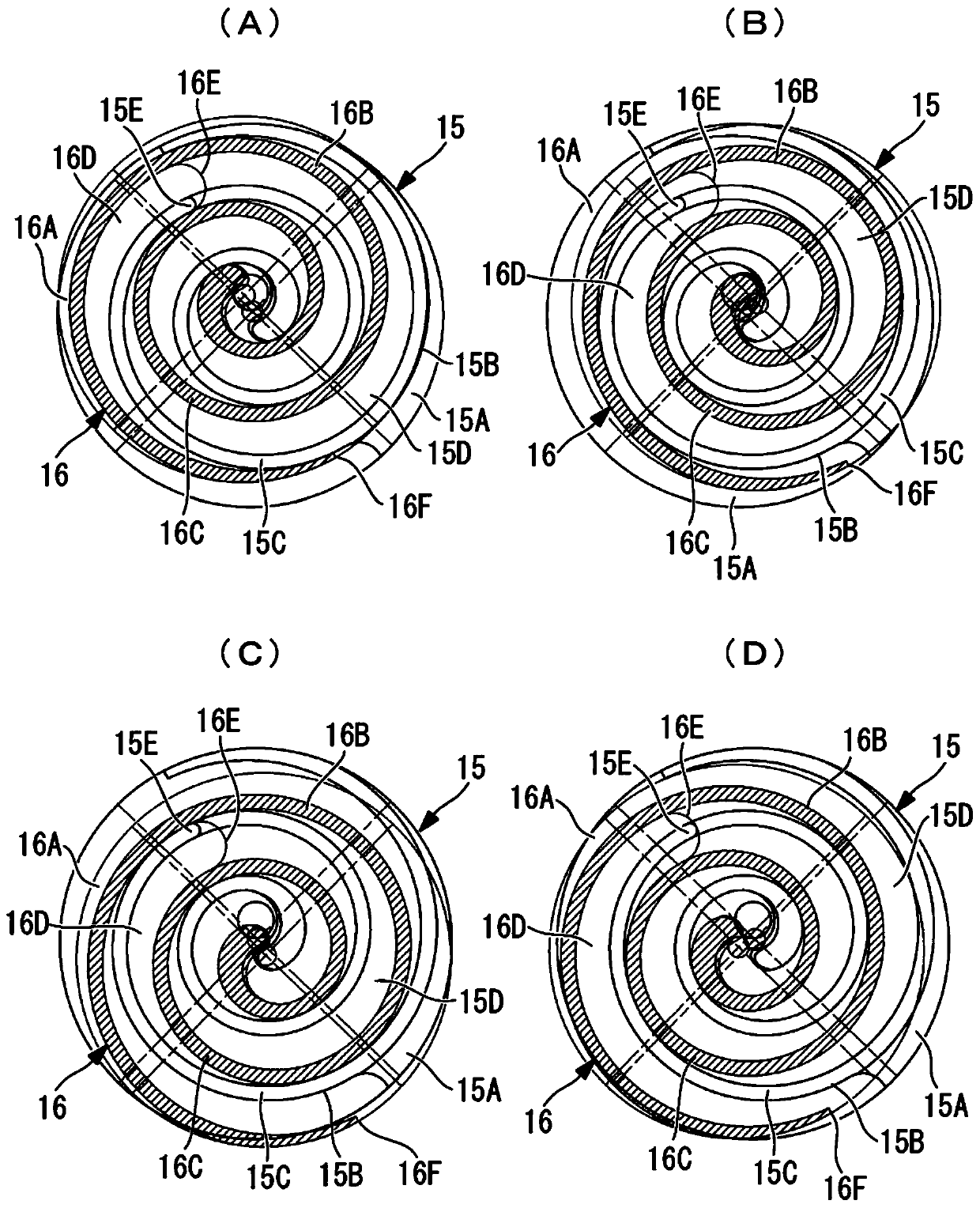

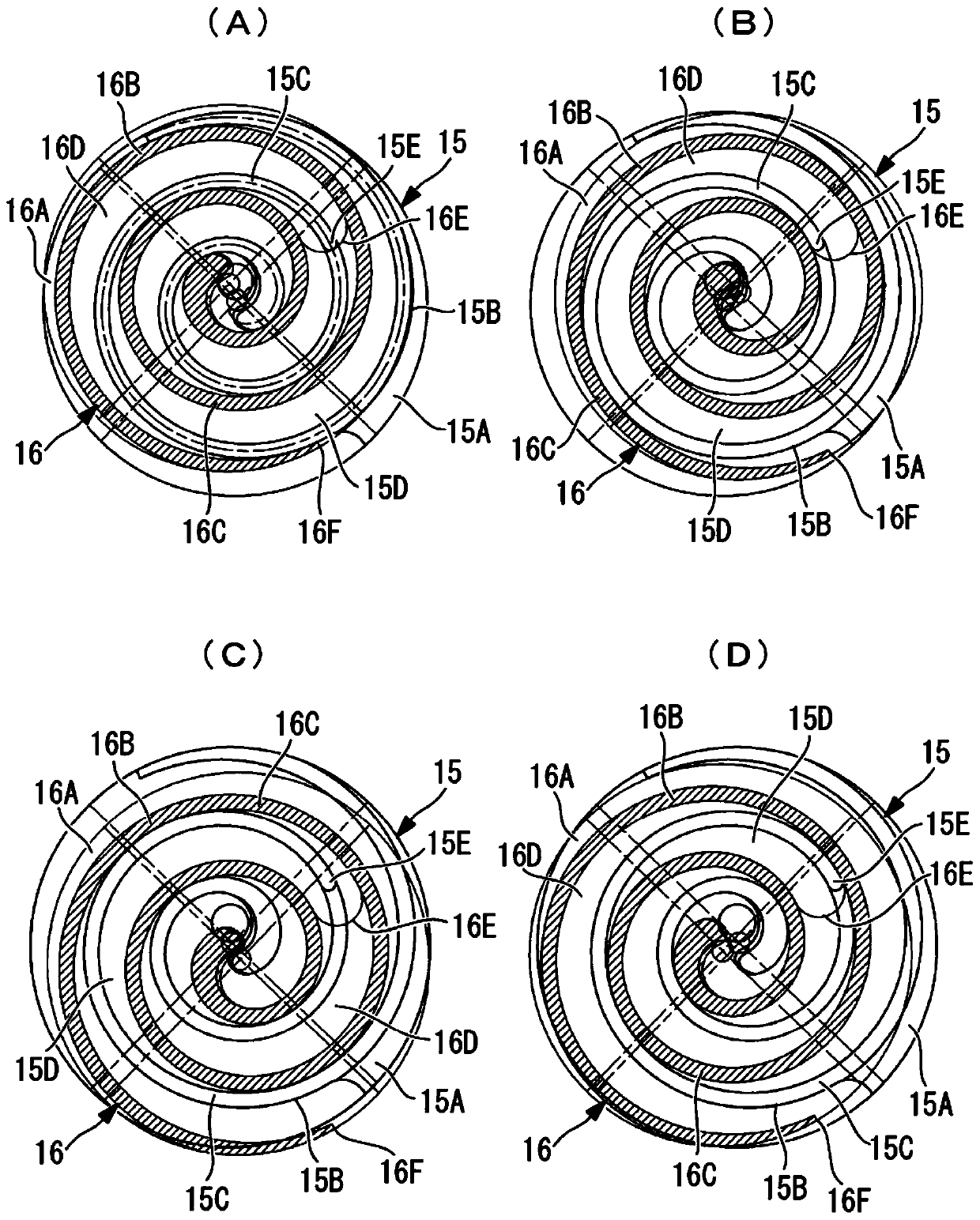

[0041] Below, use Figure 1 to Figure 5 A first embodiment of the present invention will be described.

[0042]figure 1 A longitudinal sectional view showing a scroll fluid machine according to a first embodiment of the present invention, figure 2 The explanatory diagram of the meshing state of the fixed scroll and the orbiting scroll at different orbital angle positions is shown as figure 2 (A) to figure 2 (D).

[0043] Here, as an example of a scroll fluid machine, an example of application to an open scroll compressor (scroll fluid machine) 1 of a type driven by external power will be described.

[0044] Such as figure 1 As shown, an open scroll compressor (scroll fluid machine) 1 includes a casing 2 constituting an outer contour. The housing 2 is in a cylindrical shape in which an opening is formed on the front end side and the rear end side is sealed. The front housing 3 is fastened and fixed to the opening on the front end side by bolts 4 to form a closed space i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com