Chipless cutting device

A cutting device and cutter head technology, which is applied in the field of mechanical processing, can solve the problems of high processing cost, easy damage of sliding sleeve and push rod, high processing accuracy requirements, etc., and achieve the effect of reducing maintenance cost, reducing processing difficulty and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

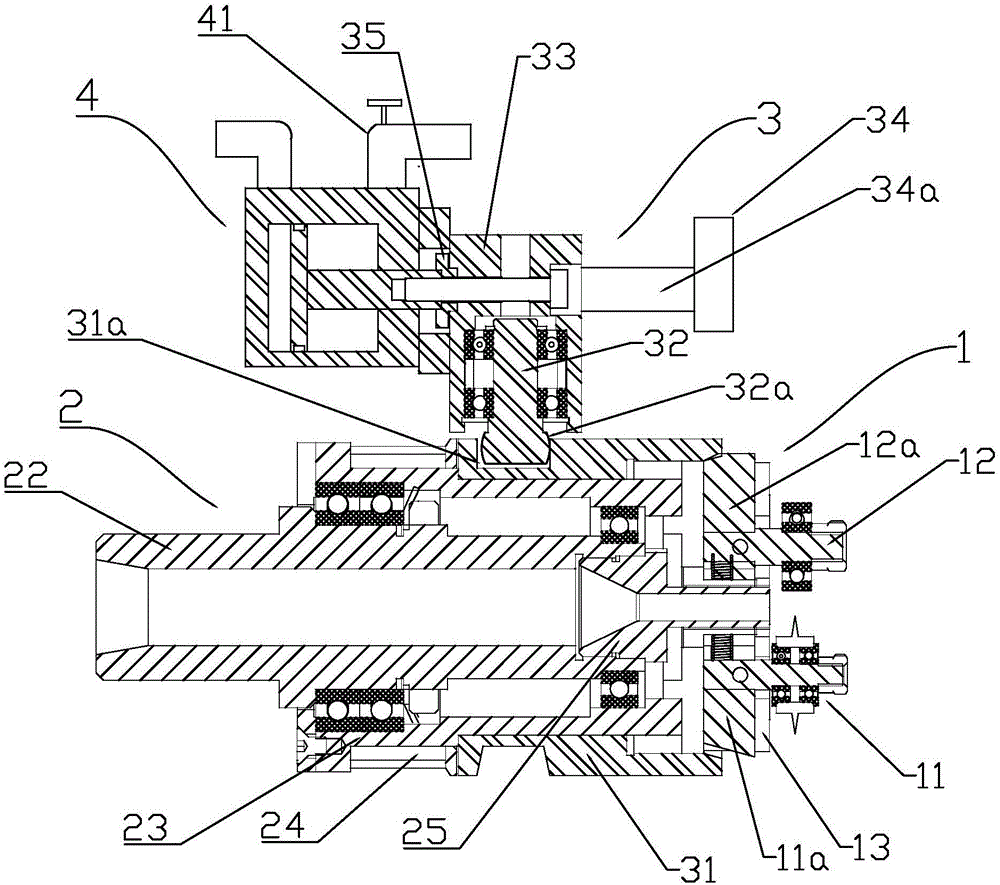

[0028] refer to Figure 1 ~ Figure 3 , The present invention is a chipless cutting device.

[0029] A chipless cutting device, comprising:

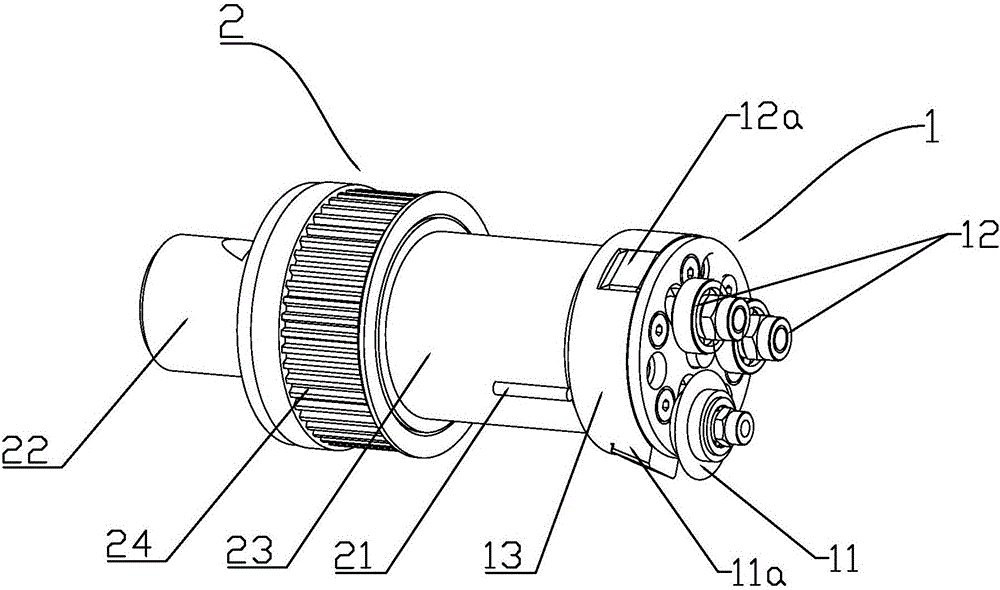

[0030] A cutter head mechanism 1, the cutter head mechanism 1 is provided with a cutter head 11 for cutting off;

[0031] A rotating mechanism 2, the rotating mechanism 2 is drivingly connected to the cutter head mechanism 1;

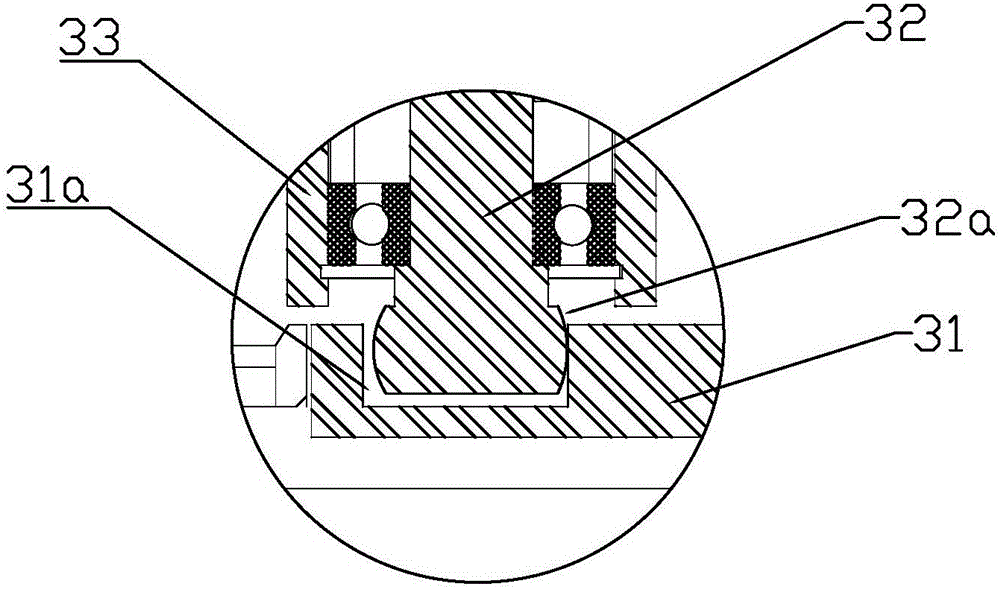

[0032] A feed mechanism 3, which includes a push rod 32 and a sliding sleeve 31;

[0033] The sliding sleeve 31 is movably fitted on the rotating mechanism 2 to drive the moving cutter head 11 to feed;

[0034] A constraining structure is provided between the push rod 32 and the sliding sleeve 31 , the constraining structure controls the relative movement of the push rod 32 and the sliding sleeve 31 along the direction of the rotation axis, and the constraining structure is a point contact constraint.

[0035] Since the cutter head mechanism 1 is in rotational motion during operation, the sliding sleeve 31 must...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com