Rotation clamping fixture

A clamping and fixture technology, which is applied in the direction of grinding workpiece supports, etc., can solve problems such as failure to meet product appearance quality requirements, poor product processing consistency, and inability to be flexible, so as to avoid product scratches, improve processing quality, and reduce The effect of hand grip strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

[0025] The orientations involved in this specification are all subject to the orientations shown in the drawings, which only represent relative positional relationships, not absolute positional relationships.

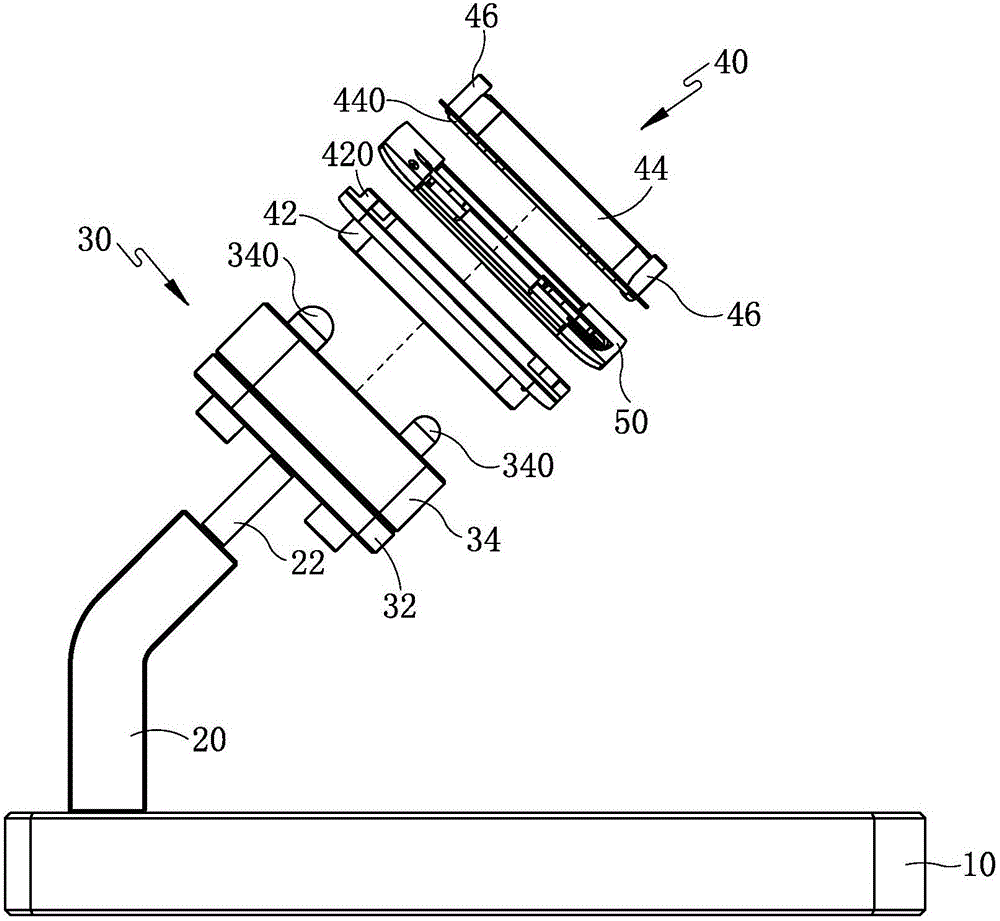

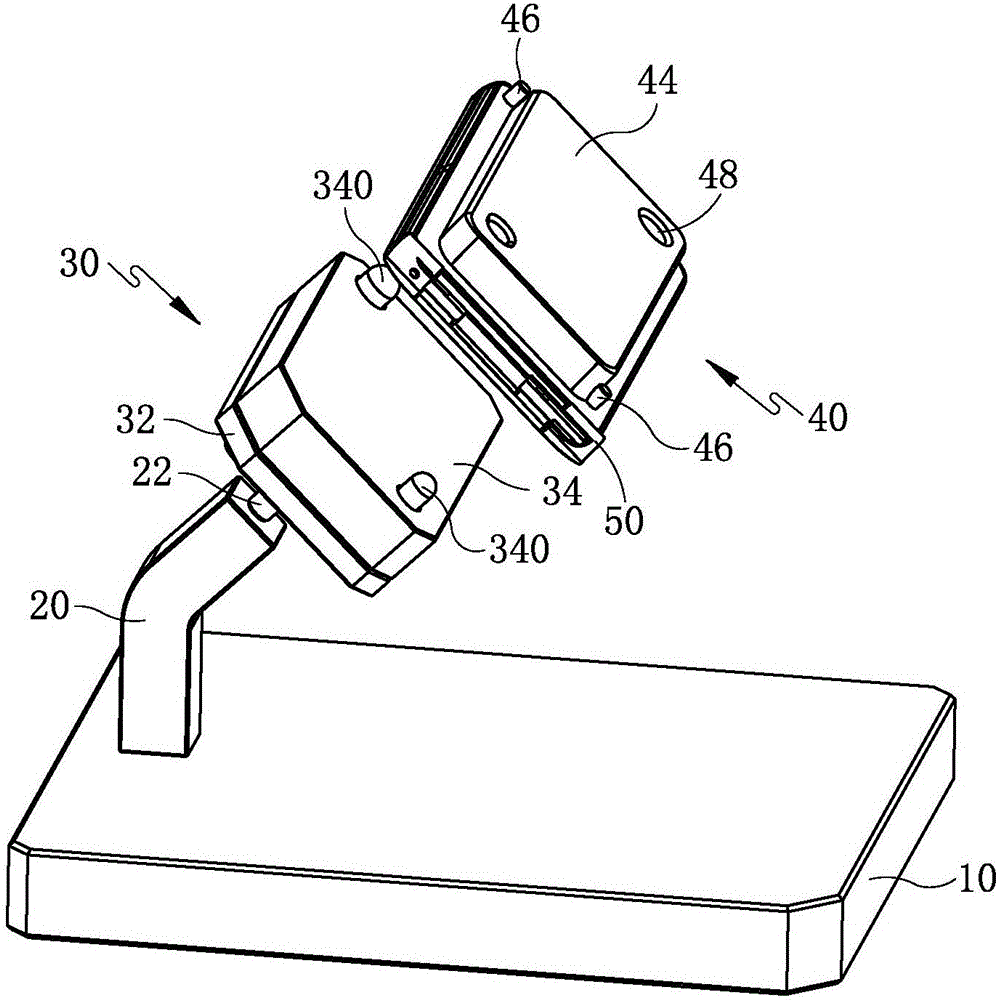

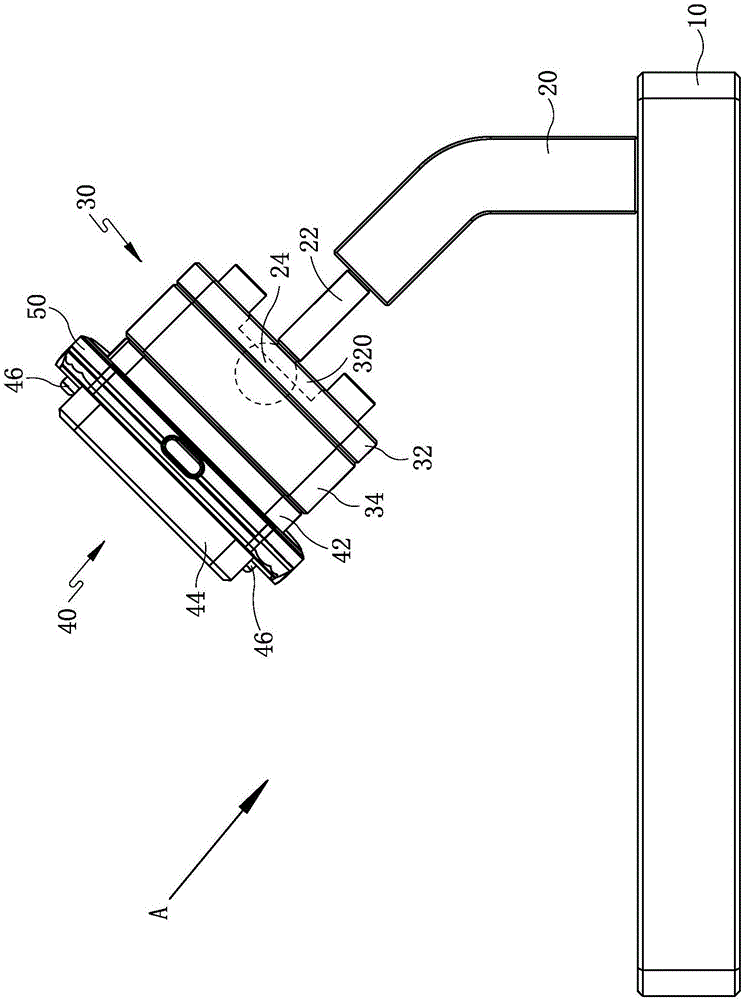

[0026] Such as figure 1 with image 3 Commonly shown, a rotary clamping fixture includes a base 10, a ball head 24 is installed on the base 10, a rotating seat 30 is installed on the ball head 24, and the rotating seat 30 can rotate around the ball head 24 in a circle of 360°, A clamping tool 40 for clamping a product 50 is detachably installed on the rotating base 30 .

[0027] Such as figure 1 , figure 2 with Figure 4 Commonly shown, in this embodiment, the swivel seat 30 is provided with a positioning pin 340, and the position corresponding to the positioning pin 340 on the clamping tool 40 is provided with a positioning pin hole 48 that is compatib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com