Modular orthorgonal-structured snake robot

A snake-shaped robot, modular technology, applied in the field of robot research and engineering, can solve problems such as non-smooth contact, contact with the surrounding environment, damage, etc., achieve the effect of compact and small shape, expand the range of activities, and avoid stuck effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

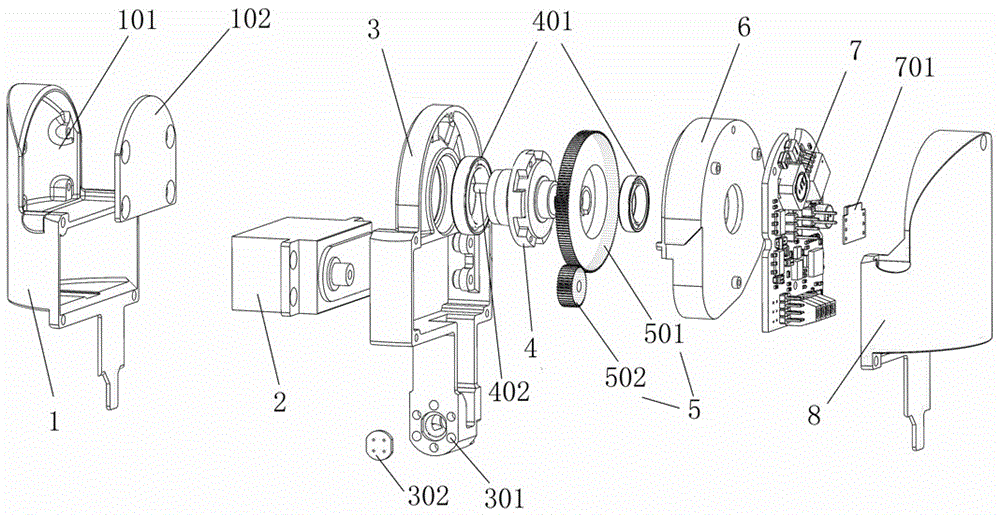

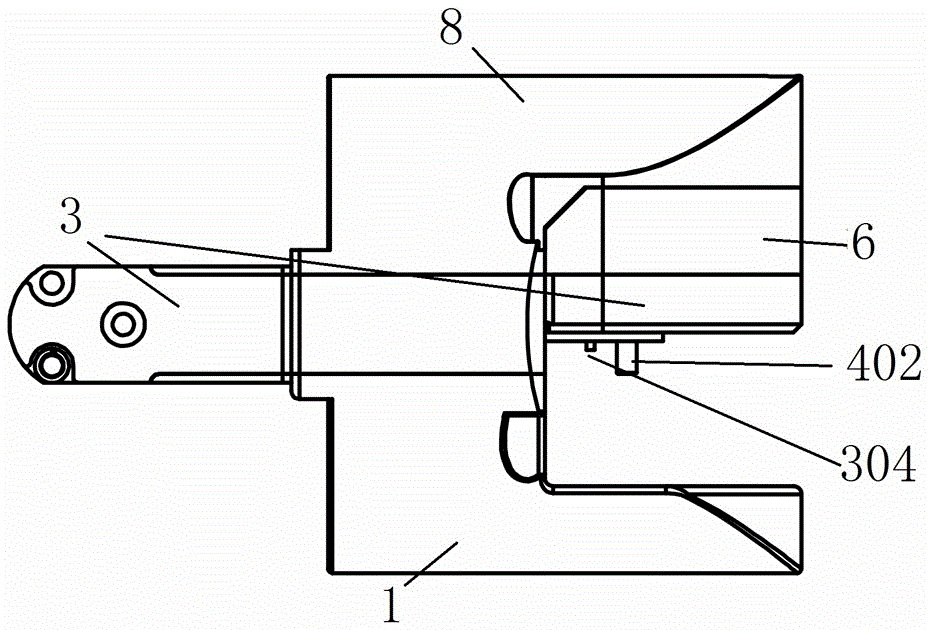

[0032] Example 1: as figure 1 As shown, the upper end of the main frame 3 of the single joint of the present invention and the bearing cover 6 are provided with through holes, the through holes are provided with bearings 401, one end of the output shaft 4 is installed in the bearing on the upper end of the main frame 3, and the other end passes through the deceleration The large tooth 501 on the device 5 is installed in the bearing on the bearing cover plate 6 . The bearing end cover 6 is connected to the main frame 3 , and the bearing 401 , the output shaft 4 and the reducer 5 are enclosed in the main frame 3 , the control system 7 is installed on the bearing end cover 6 , and the sensor system 701 is electrically connected to the control system 7 . The motor 2 is installed in the middle of the main frame 3, the motor 2 is connected with the small teeth 502, the motor 2 is placed in the hollow position of the lower end of the lower cover 1, the upper end of the lower cover 1 ...

Embodiment 2

[0040] Embodiment 2: This embodiment is similar to Embodiment 1, the difference is that the communication system adopts the CAN bus protocol to design the control system, and the communication structure of this system is adopted to improve the low communication efficiency existing in the original ordinary communication system, and the resistance to resistance is low. Poor interference ability, easy to crash and unstable.

Embodiment 3

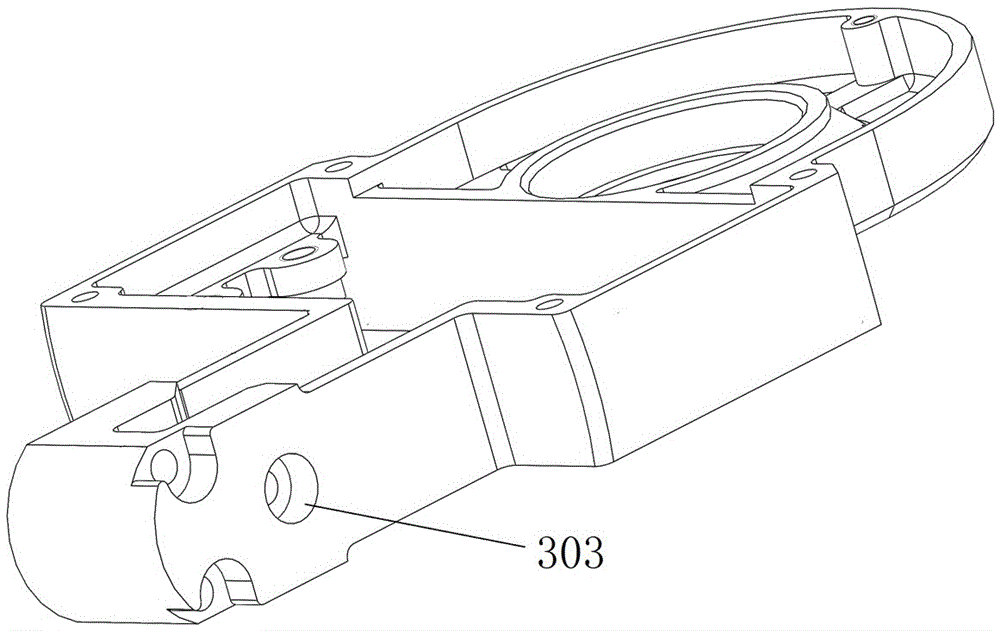

[0041] Embodiment 3: This embodiment is similar to Embodiment 2, except that, as image 3 As shown, the screw holes 303 at the lower end of the main frame for fixing the adjacent two joint modules are countersunk, and the screw heads are buried under the surface of the main frame 3, so that the main frame 3 and the lower cover of the upper section stabilize the compartment The cover plate is kept flat with no protrusions relative to the plane to prevent interference between them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com