Method for detecting printing nozzle errors in inkjet printing machine

一种喷墨印刷机、喷嘴的技术,应用在印刷、打印装置、转印材料等方向,能够解决增多废页、印刷机差负荷等问题,达到高鲁棒性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

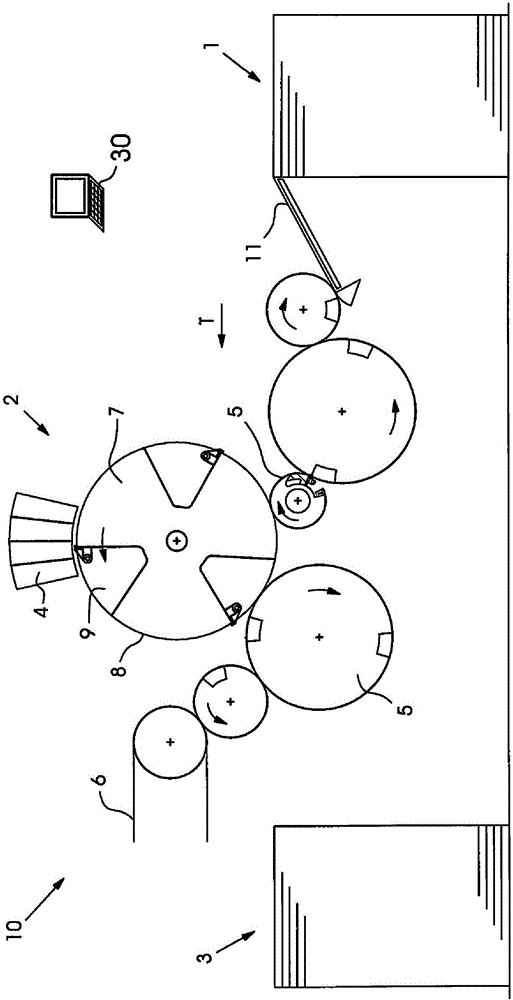

[0065] In a preferred embodiment variant, the field of application is a digital printer 10 which is configured as an inkjet sheet printer 10. in figure 1 An example of the structure of such a machine 10 is shown in. The corresponding sheet 11 is transported from the feeder 1 in the transport direction T through the printing device 2 to the receiver 3. The transport of the corresponding sheets 11 here takes place in particular by means of cylinders, namely the transport cylinder 5 and the printing cylinder 7. An inkjet print head 4 is arranged above the printing cylinder 7, which prints the sheets 11 that move through the printing cylinder 7 at small intervals. The printing cylinder 7 is therefore also referred to as an inkjet cylinder. In the embodiment shown, the printing cylinder 7 has three sheet holding areas 8 which are each separated from one another by a channel 9.

[0066] During the operation of the printing press 10, as described above, each printing nozzle in the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com