Explosion-proof heat-resistant concrete

A technology of heat-resistant concrete and refractory bricks, applied in the field of concrete, can solve problems such as poor strength, achieve high strength and improve explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

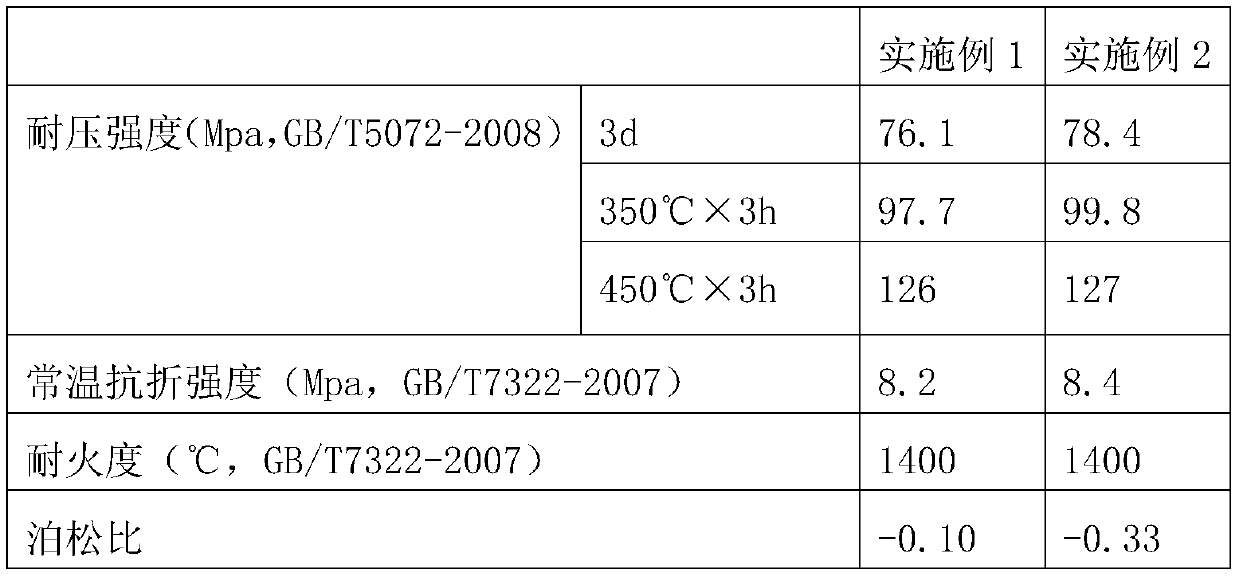

Embodiment 1

[0019] Explosion-proof and heat-resistant concrete is composed of component A and component B according to the mass ratio of 1:1. During on-site construction, component A and component B are mixed with water to make a paste. After standing for 2 hours, mix the two It can be put into use evenly.

[0020] The composition of component A is: high alumina refractory brick aggregate, ordinary 32.5 portland cement, quartz powder, sodium tripolyphosphate and fiber one. 10-16 parts by weight of high-alumina refractory brick aggregate with a particle size greater than 5 mm and less than or equal to 15 mm, 10-13 parts by weight of high-alumina refractory brick aggregate with a particle size greater than 1 mm and less than or equal to 5 mm, and a particle size greater than 0 mm and The high alumina refractory brick aggregate less than or equal to 1mm is 8-11 parts by weight. Ordinary 32.5 Portland cement is 8-10 parts by weight, quartz powder is 4-6 parts by weight, sodium tripolyphospha...

Embodiment 2

[0023] Explosion-proof and heat-resistant concrete is composed of component A and component B according to the mass ratio of 1:1. During on-site construction, component A and component B are mixed with water to make a paste. After standing for 2 hours, mix the two It can be put into use evenly.

[0024] The composition of component A is: high alumina refractory brick aggregate, ordinary 32.5 portland cement, quartz powder, sodium tripolyphosphate and fiber one. 10-16 parts by weight of high-alumina refractory brick aggregate with a particle size greater than 5 mm and less than or equal to 15 mm, 10-13 parts by weight of high-alumina refractory brick aggregate with a particle size greater than 1 mm and less than or equal to 5 mm, and a particle size greater than 0 mm and The high alumina refractory brick aggregate less than or equal to 1mm is 8-11 parts by weight. Ordinary 32.5 Portland cement is 8-10 parts by weight, quartz powder is 4-6 parts by weight, sodium tripolyphospha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com