Runner crown structure of rotating wheel of water turbine

A crown-on-wheel and water-turbine technology, which is applied in hydroelectric power generation, mechanical equipment, machines/engines, etc., can solve the problems of insufficient transitional arcs and large changes in thickness, and achieve guaranteed use effects, reasonable structure, and convenient and reliable use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

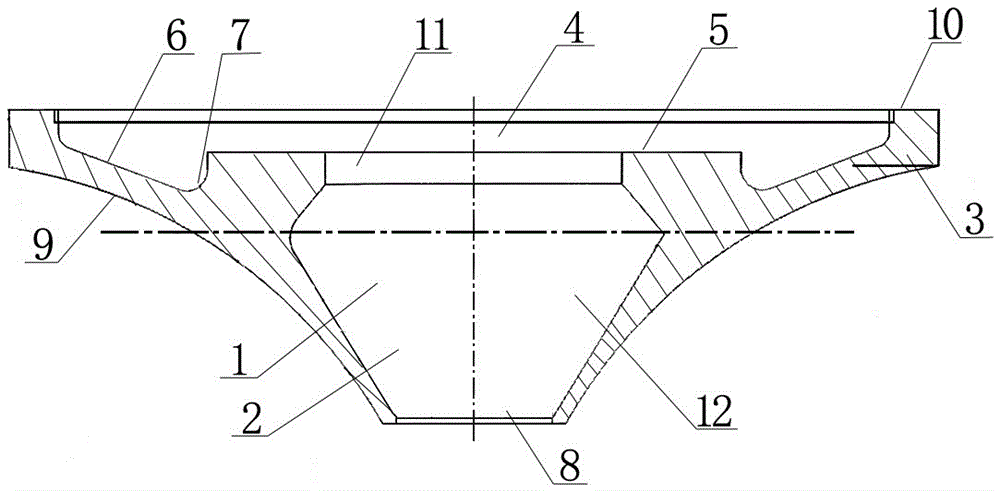

[0008] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the crown structure of a water turbine runner according to the present invention includes a wheel-shaped crown body 2 with an axial through hole 1 in the middle, and the large-diameter wheel disc 3 of the crown body 2 is located at The upper end side, the upper surface of the upper end side is provided with a recessed special-shaped ring groove 4, wherein: a downwardly recessed platform surface 5 is arranged in the middle, an axial through hole 11 is formed in the middle of the upper end, and an oblique groove is formed on the periphery of the platform surface 5. An annular groove 6 on the bottom surface, and a circular arc transition 7 is formed on the inner and outer ends of the annular groove 6; the lower end of the axial through hole 11 of the upper end is connected with a thick waist-shaped through hole 12 in the middle until the lower end of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com