Compressor pump body, compressor and assembly method of compressor pump body

A compressor pump and assembly method technology, which is applied in the field of compressors, can solve the problems of large friction power consumption and large impact on compressor performance, and achieve the effects of reducing friction power consumption, reducing relative motion linear velocity, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

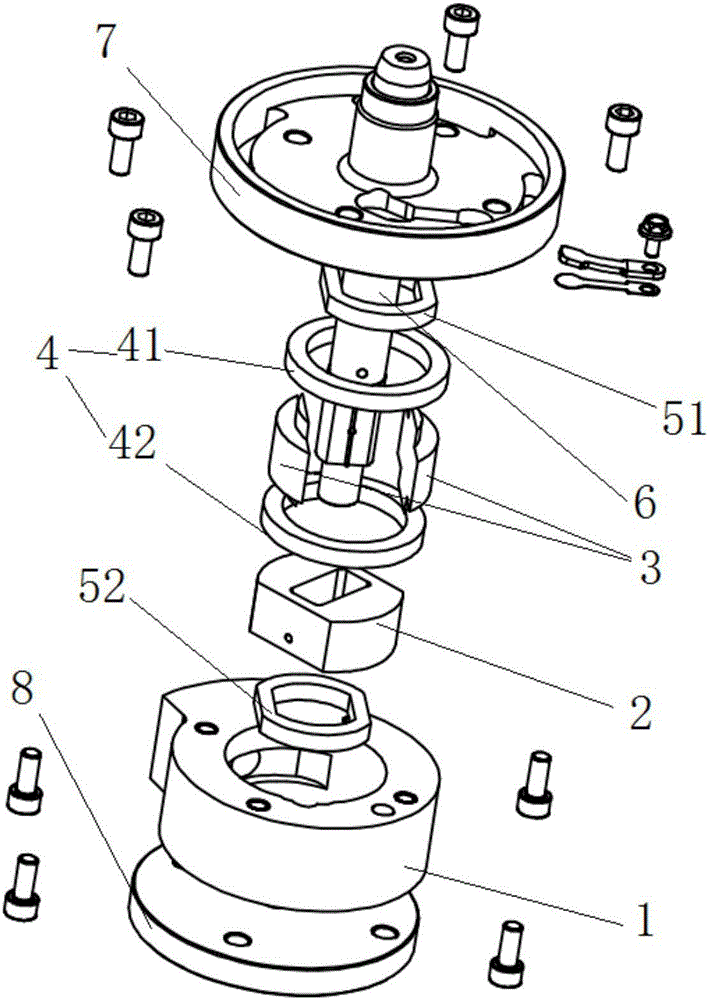

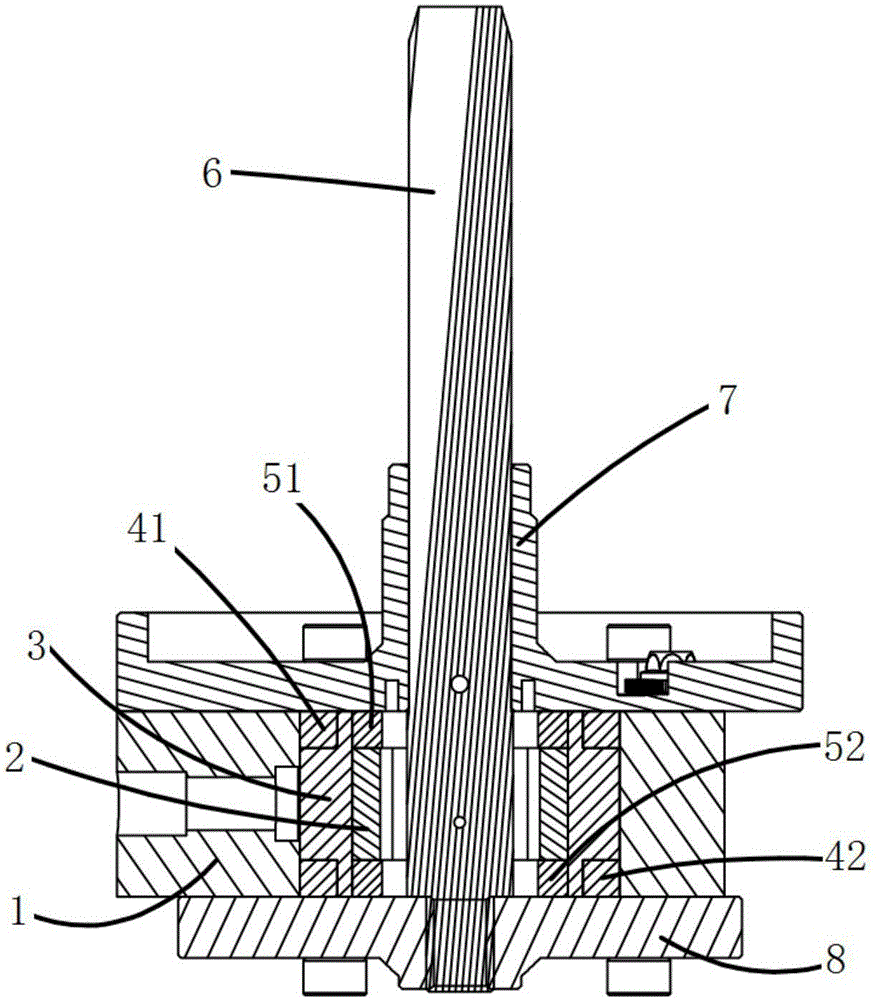

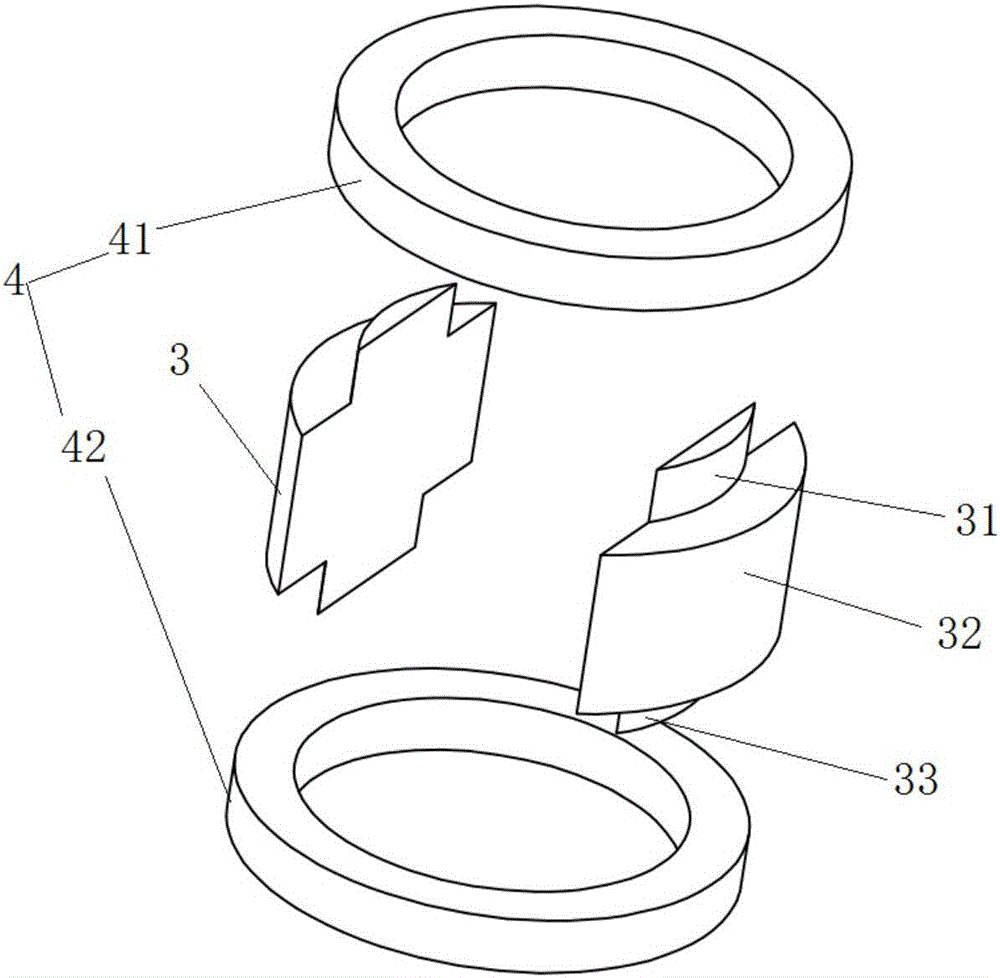

[0061] This embodiment provides a compressor pump body, such as figure 1 and figure 2 As shown, the pump body of the compressor in this embodiment includes a cylinder 1 , a piston 2 , a slider 3 and a limiting structure 4 . Wherein, the piston 2 is movably installed in the cylinder 1, and the outer circumference of the piston 2 includes a first plane and a first arc surface. A slider 3 is installed between the first plane of the piston 2 and the inner surface of the cylinder 1 ; the first arc surface of the piston 2 is adapted to the inner surface of the cylinder 1 . Wherein, the outer circumference of the slider 3 includes a second plane and a second arc surface, and the second plane on the slider 3 cooperates with the first plane on the piston 2 to ensure that the piston 2 can operate normally in the cylinder; and the slider The second arc on the 3 is adapted to the inner surface of the cylinder 1. The limiting structure is connected with the slider 3 and is used for li...

Embodiment 2

[0066] Preferably, this embodiment provides a compressor pump body. Compared with the previous embodiment, this embodiment further designs the limiting structure as follows:

[0067] Such as Figure 2 to Figure 6 As shown, the limiting structure in this embodiment includes a limiting collar 4 . Wherein, the limiting collar 4 is located in the cylinder 1 , and all the sliders 3 are sheathed in the limiting collar 4 together. Here, in this embodiment, the limiting structure is set as the limiting collar 4, so that all the sliders 3 are sleeved in the limiting collar 4 together, so that the limiting collar 4 can limit the sliders. position, so as to prevent the slider 3 from moving outwards (toward the inner surface of the cylinder) when the compressor is working, so as to prevent the outer circular surface (the second arc surface) of the slider 3 from contacting the inner surface of the cylinder 1, thereby reducing the corresponding Friction power consumption.

[0068] Here, ...

Embodiment 3

[0073] Preferably, this embodiment provides a compressor pump body, compared with Embodiment 2, such as Figure 1 to Figure 4 and Figure 6 As shown, there are two limiting collars 4 in this embodiment, that is, the first limiting collar 41 and the second limiting collar 42; wherein, the upper ends of all the sliders 3 are sleeved on the first Inside the limiting collar 41 ; the lower ends of all the sliders 3 are sheathed in the second limiting collar 42 together.

[0074] In this embodiment, two spacer collars are provided to limit the upper end and the lower end of the slider 3 at the same time, so that the stability of the position limitation is better, and the contact between the slider 3 and the inner surface of the cylinder 1 can be further avoided, and further Reduce the frictional power consumption between the slider 3 and the cylinder 1, and reduce the frictional power consumption of the compressor to improve the performance of the compressor.

[0075] Preferably, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com