Explosion-proof method for upright oil and gas pipeline

An explosion-proof and pipeline technology, which is applied in the direction of pipe components, pipeline heating/cooling, pipes/pipe joints/fittings, etc., can solve the problems that it is difficult to ensure the explosion-proof effect of oil and gas pipelines, and the soil cannot be fixed stably, so as to facilitate large-scale Popularization and application, good flameproof effect, and the effect of avoiding overheating of the nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

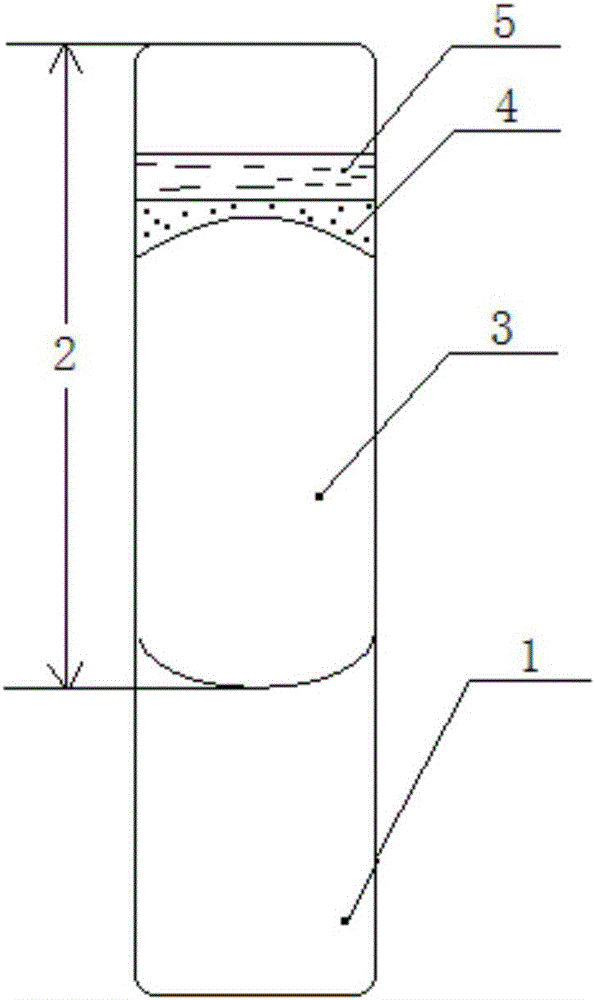

[0042] This embodiment provides a flameproof method for vertical oil and gas pipelines, and the specific steps are as follows:

[0043] Step 1: Take the area 60cm away from the nozzle of the vertical oil and gas pipeline 1 as the explosion-proof area 2, polish the inner wall of the explosion-proof area 2 with sandpaper, and then wipe it with cotton cloth or gauze to make the inner wall of the explosion-proof area 2 smooth ,clean.

[0044] Step 2: Place the explosive waterproof rubber sleeve 3 produced by Juneng Spacer Co., Ltd. in the explosion-proof area 2, and fill the explosive waterproof rubber sleeve 3 with nitrogen as a protective gas until the explosive waterproof rubber sleeve 3 and the explosion-proof area 2 The inner walls are in close contact to isolate the combustible gas in the vertical oil and gas pipeline 1.

[0045] Step 3: Add loam with an average particle size of 0.1mm to the explosion-proof area 2 to form a sand layer 4 to cover the top of the explosive wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com