Inverted GaN power device packaging structure and preparation method thereof

A technology of power devices and packaging structures, applied in the field of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to deepen the understanding of the present invention, the specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is only used to explain the present invention and does not constitute a limitation to the protection scope of the present invention.

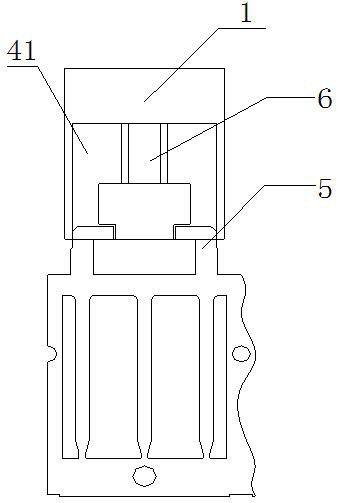

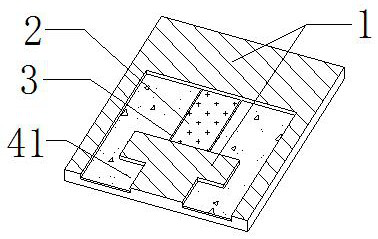

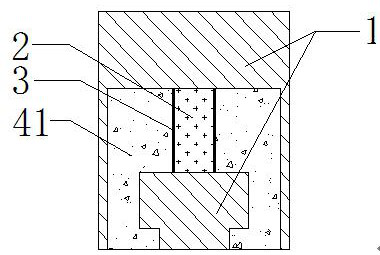

[0026] Such as Figure 1-8 As shown, a flip-chip GaN power device packaging structure includes a ceramic substrate 1. The ceramic substrate 1 has a rectangular shape and a material thickness of 1mm. The shape of the body is inverted "concave". The bottom of the slotted tank and the back of the ceramic substrate are respectively covered with a front copper layer 41 and a rear copper layer 42. The thickness of the copper layer is 0.15mm. The upper middle of the inverted "concave" tank is coated with There is insulating varnish 2, the thickness of insulating varnish 2 is 0.015mm, there is a V groove 3 between the two sides of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com