Double chip safety soldering fixture with induction detection

A welding fixture and induction detection technology, applied in the field of double-chip welding fixtures, can solve problems such as low welding efficiency and difficulty in controlling welding quality, and achieve the effects of ensuring safe welding, reducing costs, and high-quality welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

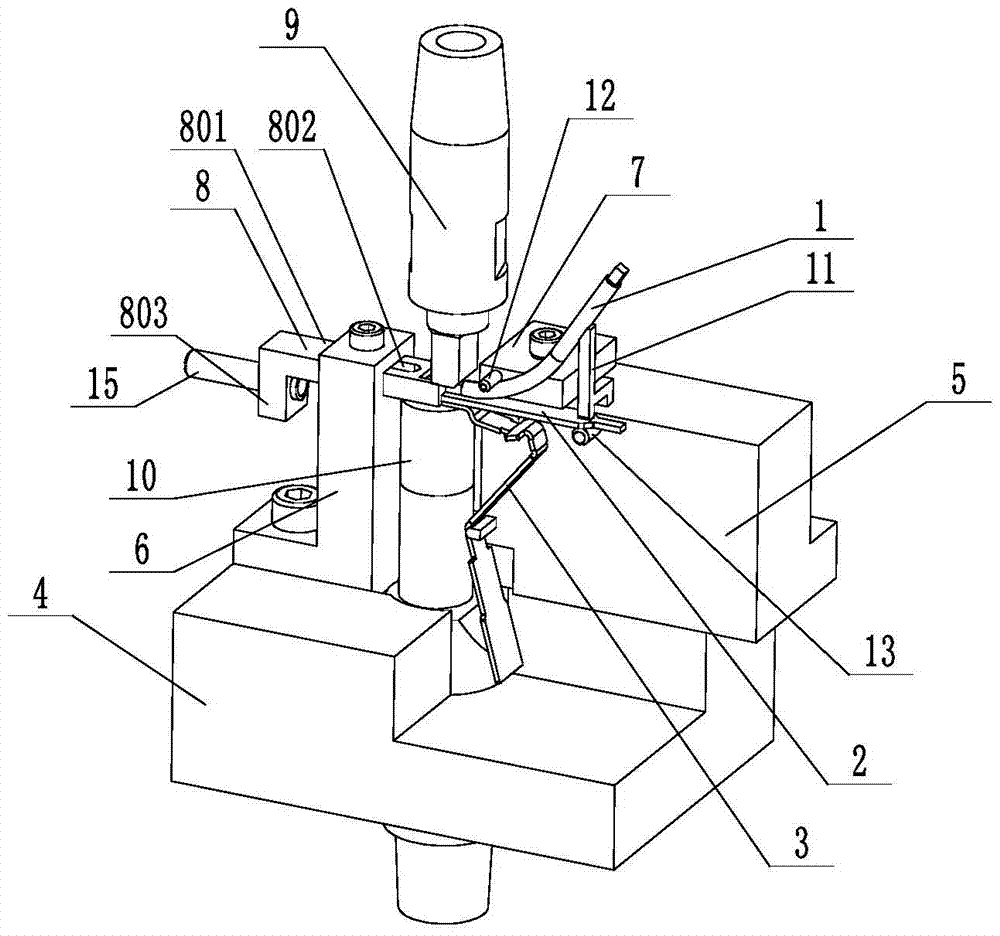

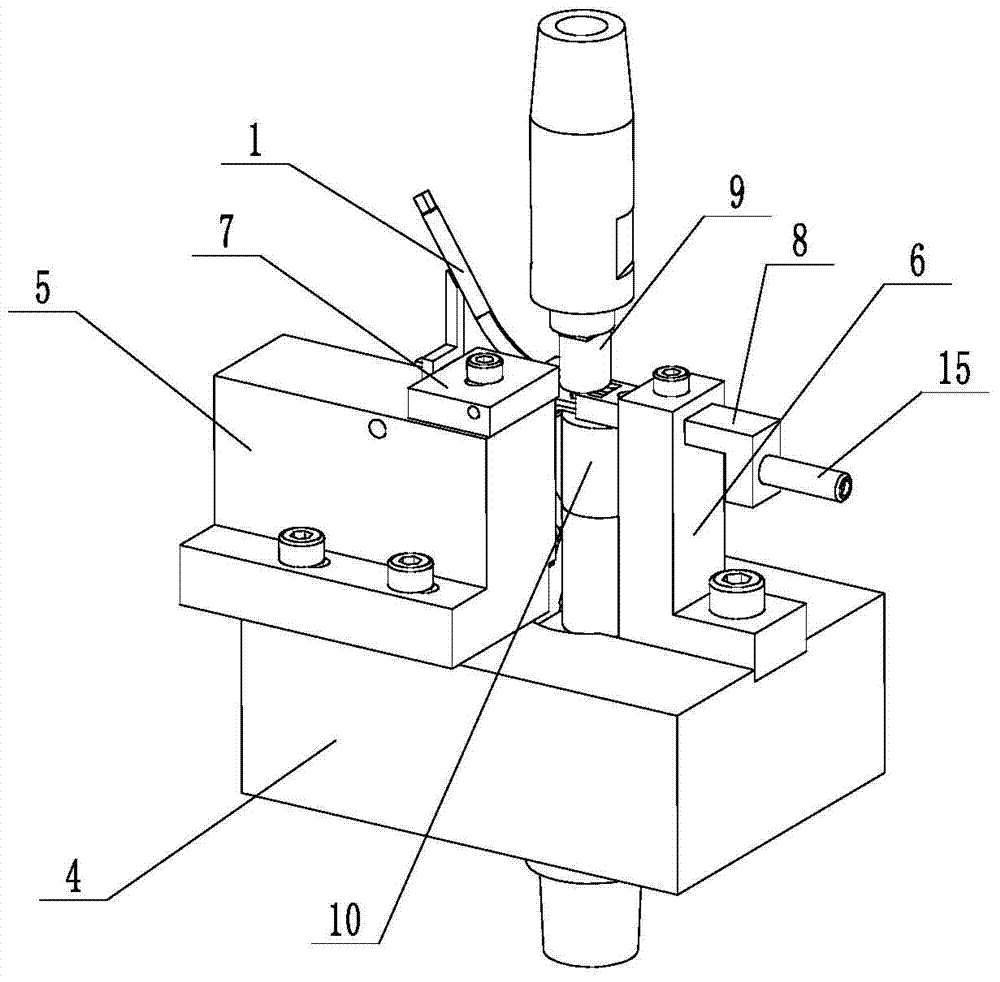

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

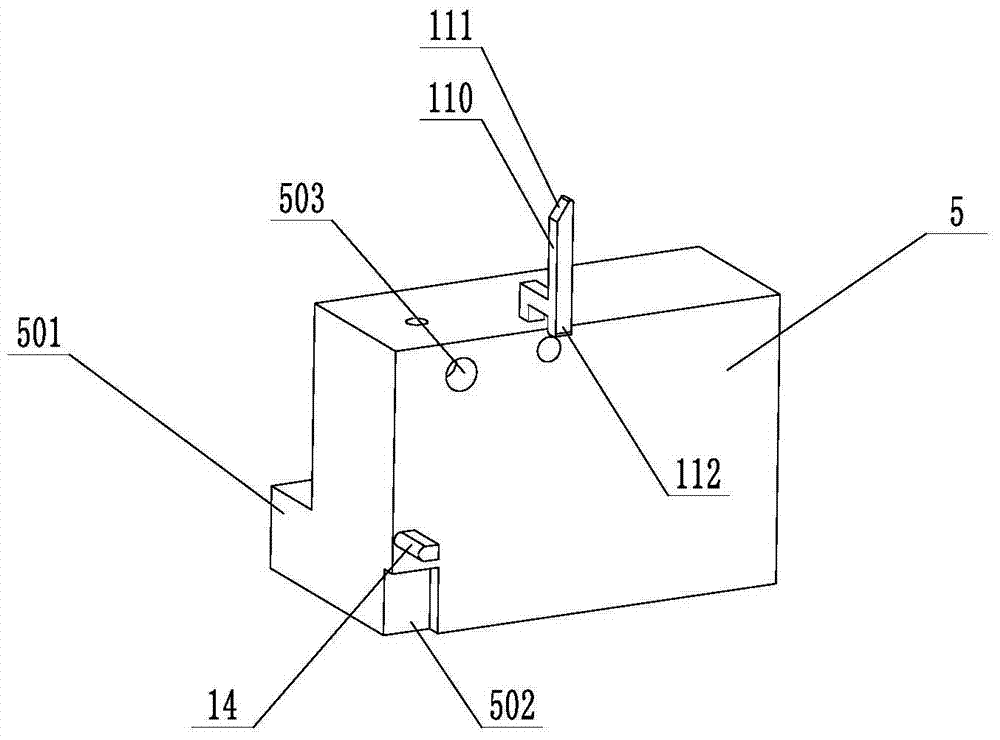

[0022] like Figure 5 As shown, the dual-chip safety welding fixture with induction detection in this embodiment is used for welding between the double-chip 2, the copper wire 1 and the support plate 3, the copper wire 1 is curved, and its welding end is a square tube end 101, the support plate 3 is a multi-bending structure, which has an upper horizontal plate welding end 301, a middle middle bending part 302 and a lower lower bending part 303, the middle bending part 302 and the lower bending part 303 The direction of deflection is opposite.

[0023] like figure 1 , figure 2 As shown, the welding jig includes a welding seat 4, the center of the welding seat 4 is equipped with a lower fixed electrode 10, and an upper movable electrode 9 is arranged above the lower fixed electrode 10, and is installed on the welding seat 4 on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com