Terminal compaction wire device

A terminal and crimping sleeve technology, applied in the field of online crimping, can solve the problems of unsightly appearance, uneven terminal crimping seam, time-consuming and labor-intensive etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

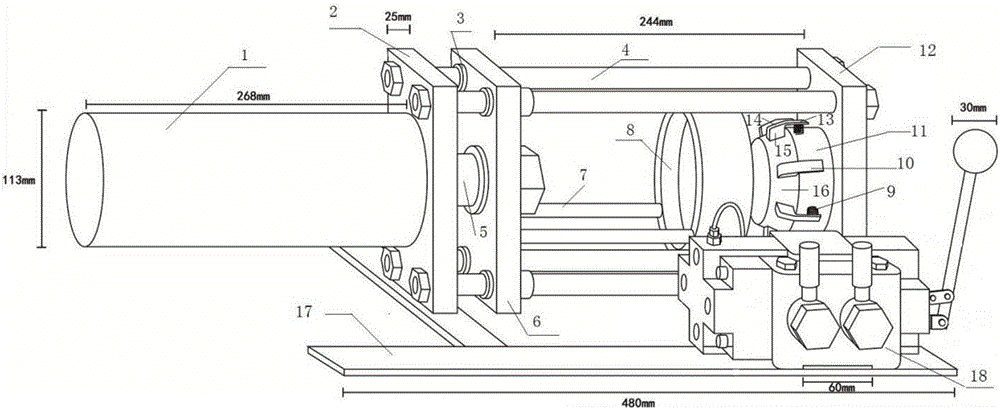

[0013] A terminal pressing line device, comprising a first oil cylinder seat, a second oil cylinder seat, an oil cylinder, and a mould, the first oil cylinder seat and the second oil cylinder seat are connected through oil cylinder slideways, and the first oil cylinder seat fixes the oil cylinder on On it, the cylinder core of the oil cylinder is connected with the slide block, and the slide block is slidably connected to the slideway. The slide block supports and forms a fixed connection to the mold press frame sleeve through the mold support, and the second oil cylinder base fixes the mold base on the On it, the mold seat includes a straight cylinder and a variable diameter cylinder in front of which tends to the direction of the straight cylinder and gradually increases in radius. The moving mold hole has a spring corresponding to the mold hole on the straight cylinder. The mold includes a straight plate and a rectangular column with an inclined bottom surface. The straight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com