Movable center mechanism for formed grinding machine

A technology of gear grinding machine and top, applied in the direction of gear cutting machine, tailstock/top, gear teeth, etc. It can solve the problems that the top cannot be adjusted independently in the radial direction, and the top cannot be adjusted independently, so as to change the pressing force and reduce the resistance , the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

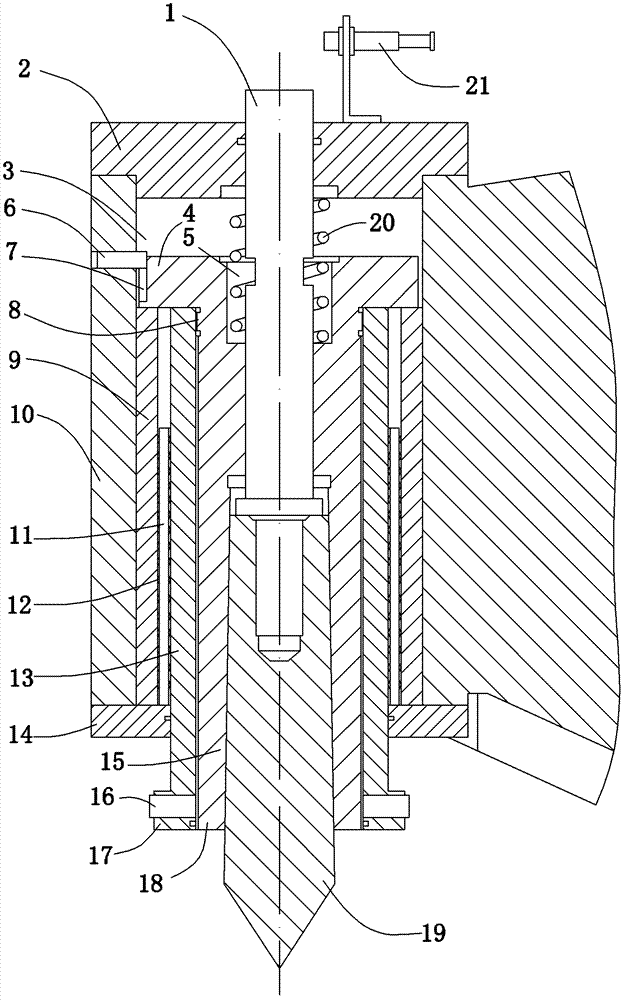

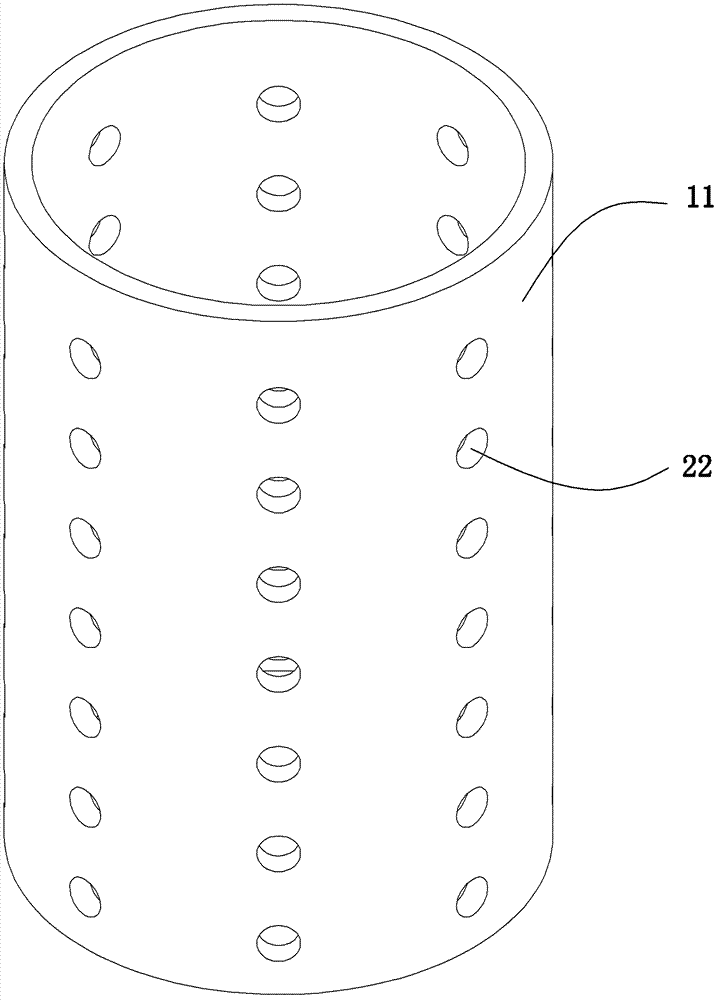

[0021] Example: a movable top mechanism of a forming gear grinding machine (see attached figure 1 ), including a bracket 10, the bracket is arranged on the machine tool of the gear grinding machine, the bracket is provided with an axial circular hole 3, and the two ends of the axial circular hole are respectively fixed with a top front connecting plate 14 and a top rear connecting plate 2. A middle circular hole is arranged in the middle, and a bolt hole is arranged in the middle of the rear end plate. A T-shaped center sleeve 15 is arranged in the axial circular hole. The center sleeve includes a disk portion 4 and a cylindrical portion 18, and the disk portion is perpendicular to the cylindrical portion. The outer diameter of the disc portion is matched with the inner diameter of the axial circular hole, the outer peripheral surface of the disc portion is provided with an axial chute 7, the corresponding part of the bracket is provided with a threaded hole, and the threaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com