A pipeline in-situ linear adjustment system and adjustment method

A linear adjustment and pipeline technology, used in tunnels, earth-moving drilling, tunnel lining, etc., can solve the problems of inapplicable pipe jacking, small sinking of pipes or tunnels, and failure to meet the height requirements of jacking pipes. Linear adjustment effect, good jacking effect, good water stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

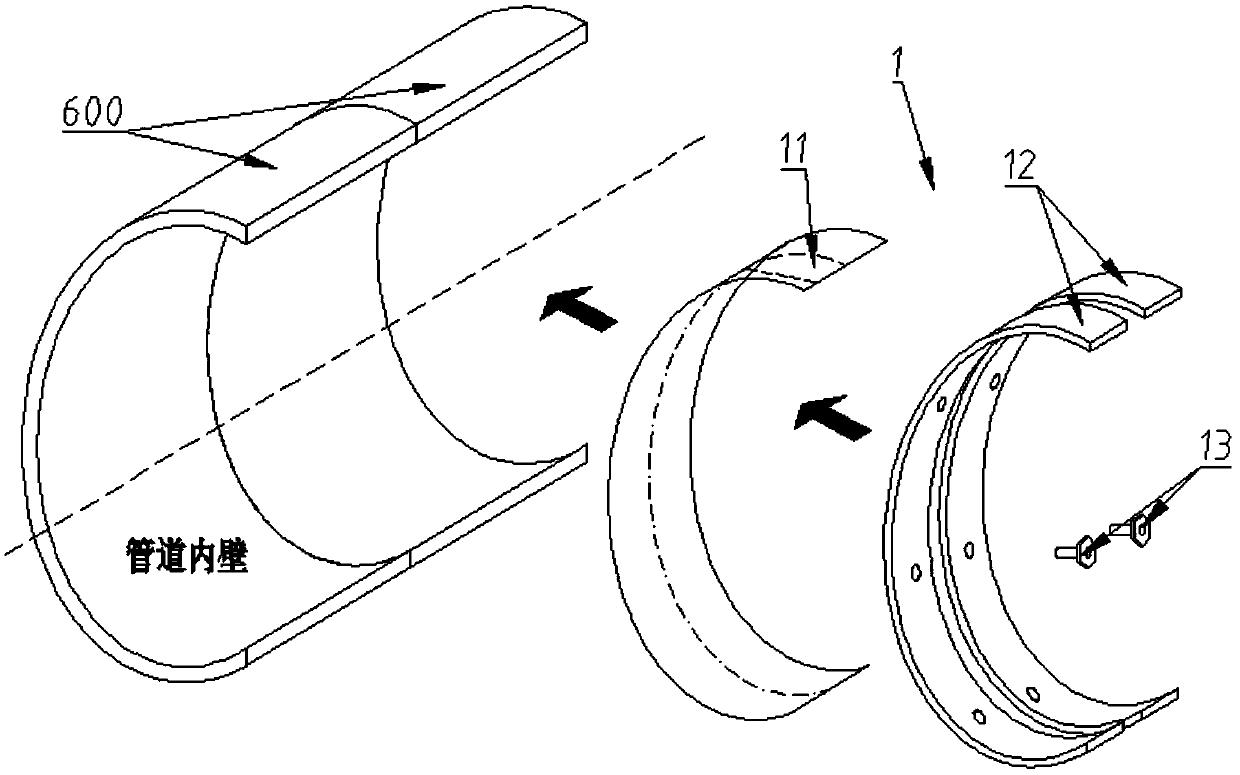

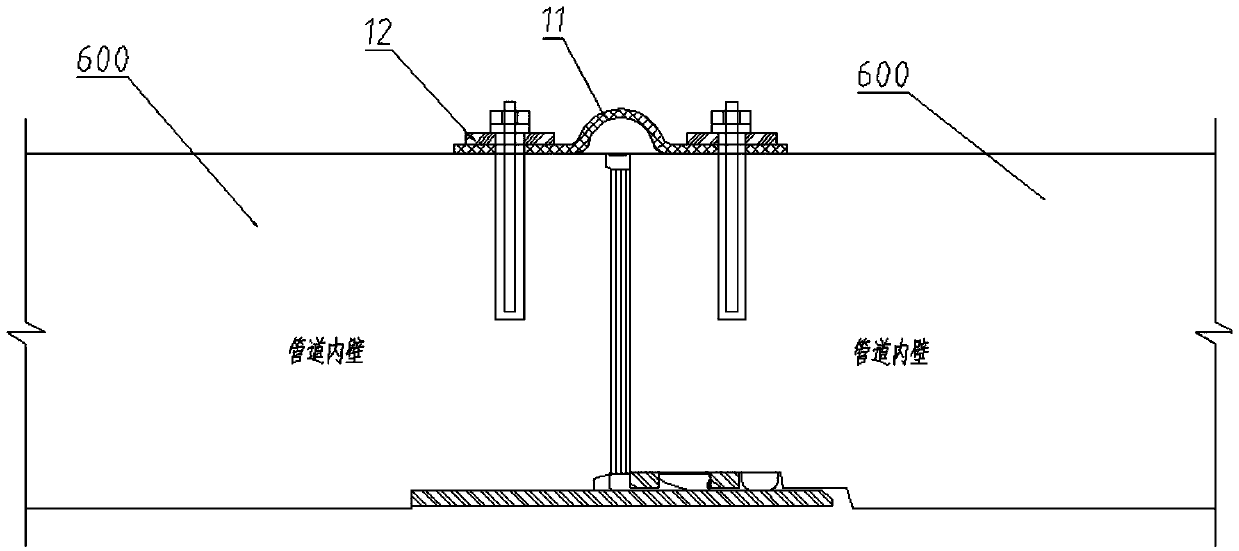

[0045] An in-situ linear adjustment system for pipelines includes a plurality of water stop devices 1 , jacking devices 2 and grouting devices 4 . The water stop device 1 is arranged at the junction of adjacent pipe joints in the sinking pipeline to fill the gap caused by the misalignment of the pipe joints 600, and can also play the role of water stop. The jacking device 2 is arranged in the pipeline for lifting the submerged pipe joint 600 to its original position, and the grouting device 4 is used for grouting the lower soil layer after the sunken pipe joint 600 is lifted.

[0046] Such as figure 1As shown, the water stop device 1 adopts an internal expansion ring water stop device, and each internal expansion ring water stop device includes a rubber pad water stop 11 and two curved steel pressure plates 12, and the rubber pad water stop 11 has a certain width, and it fits on the inner walls of two adjacent and misaligned pipe joints 600, so that the rubber pad waterstop 1...

Embodiment 2

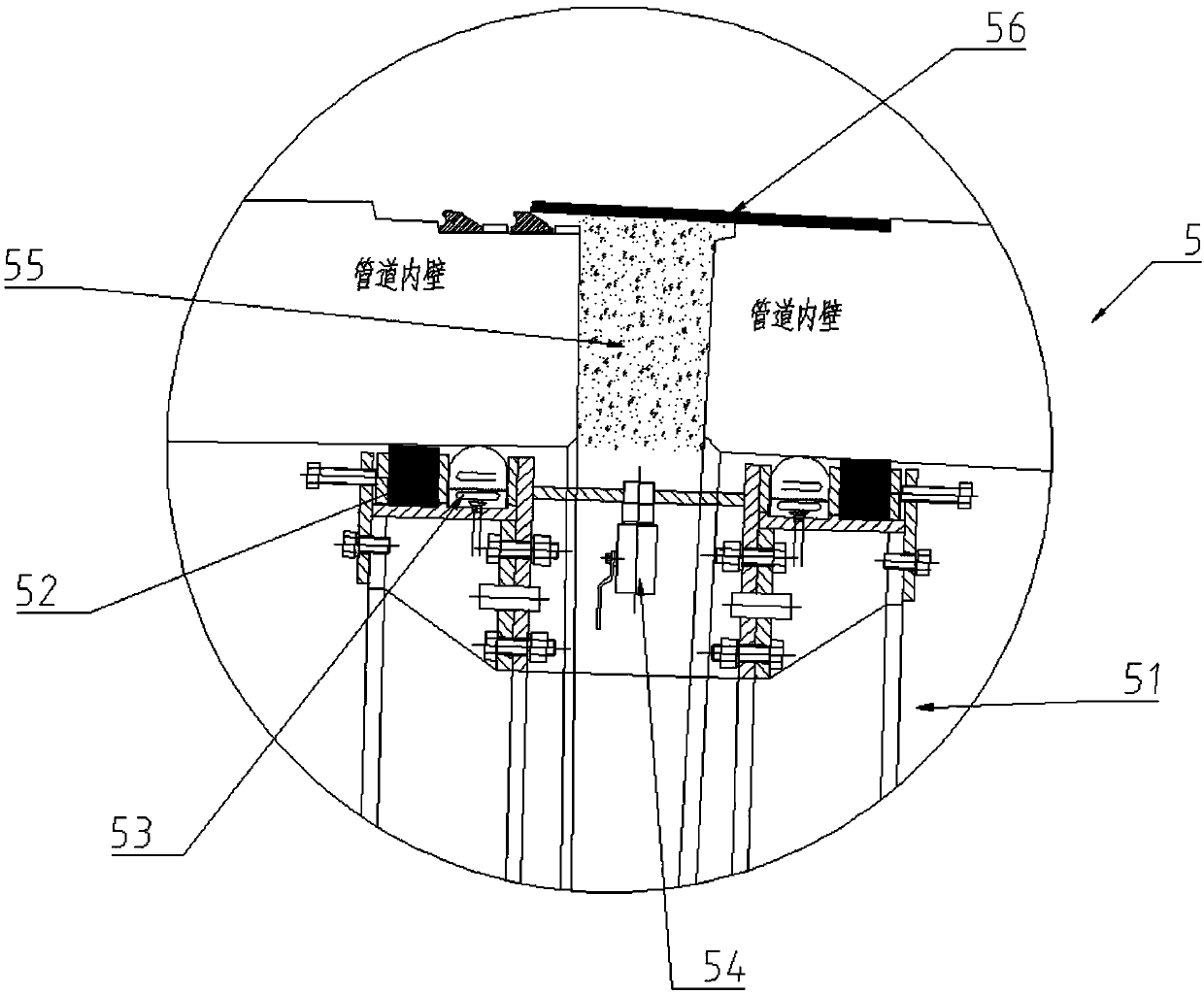

[0060] The difference between the second embodiment and the first embodiment is that the water stop device adopts the inflatable water stop device 5 instead of the internal expansion ring water stop device.

[0061] The inflatable water-stop device includes a steel collar 51 with a diameter slightly smaller than the inner diameter of the pipe, and an inflatable water-stop rubber belt 52 and a compressible water-stop packing 53 arranged on the peripheral surface of the steel collar 51. Both sides of the collar 51 in the axial direction are provided with an inflatable water-stop rubber belt 51 and a water-stop packing 53 to respectively cooperate with two adjacent pipe joints 600 so as to seal the gap at the joint of the pipe joints 600, and the The inflatable water-stop rubber belt 52 and the compressible water-stop packing 53 are squeezed between the steel collar 51 and the inner wall of the pipe to closely contact with the pipe wall so as to realize the water-stop effect.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com