Suspension train clamping brake device

A brake device and clamping technology, which is applied in railway brake systems, brakes for special railway systems, transportation and packaging, etc., can solve problems such as failure of the brake system and failure to stop, and achieve increased Friction, simple structure, and the effect of increasing the friction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

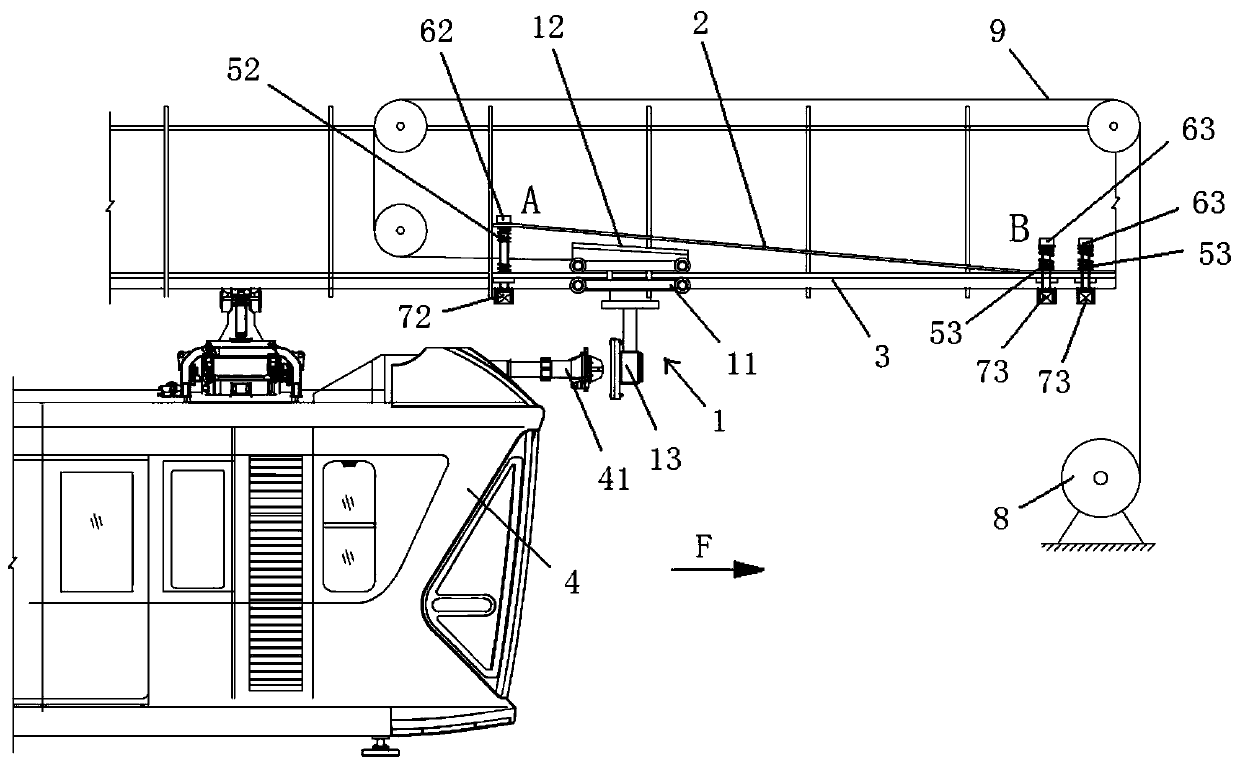

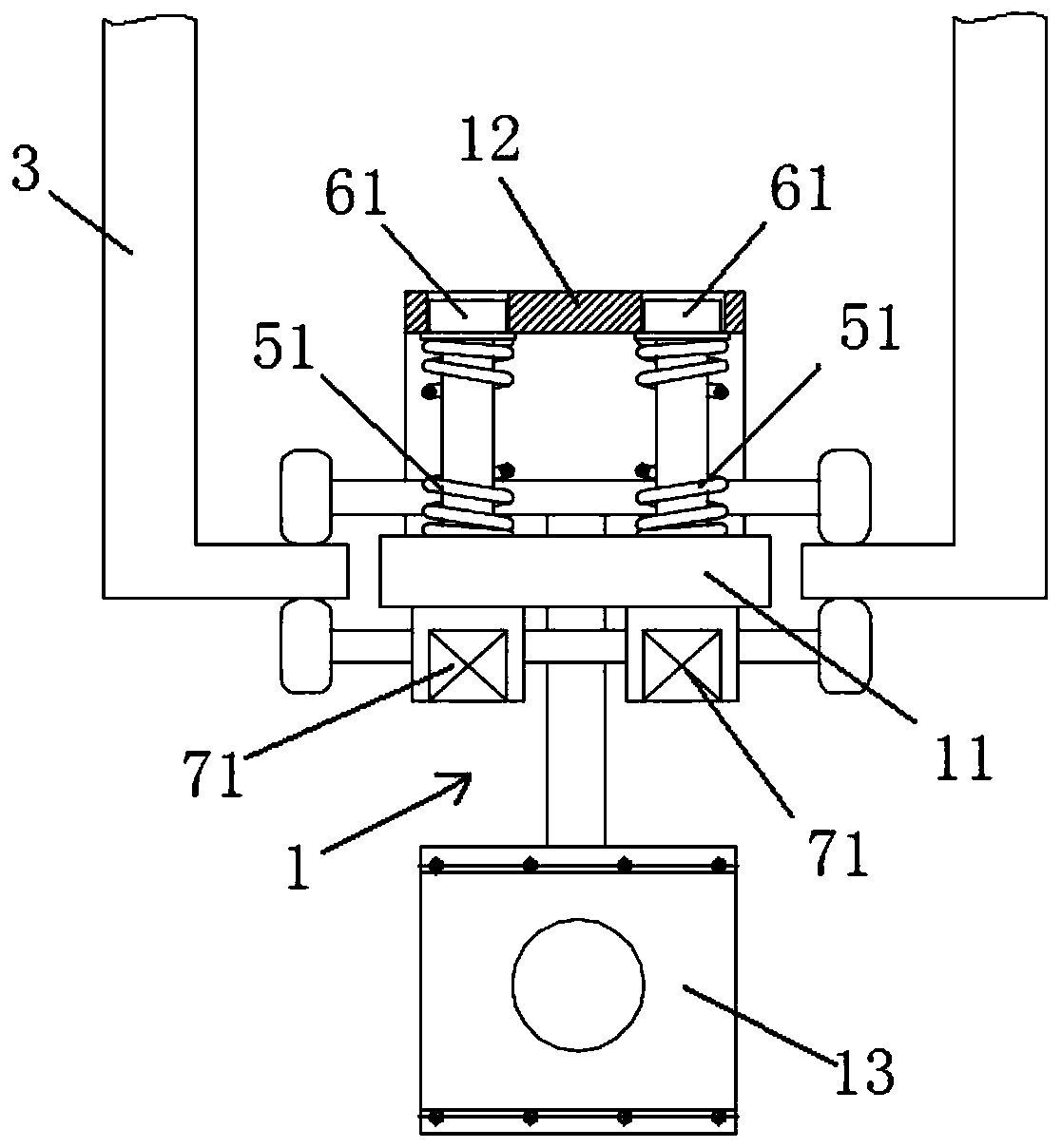

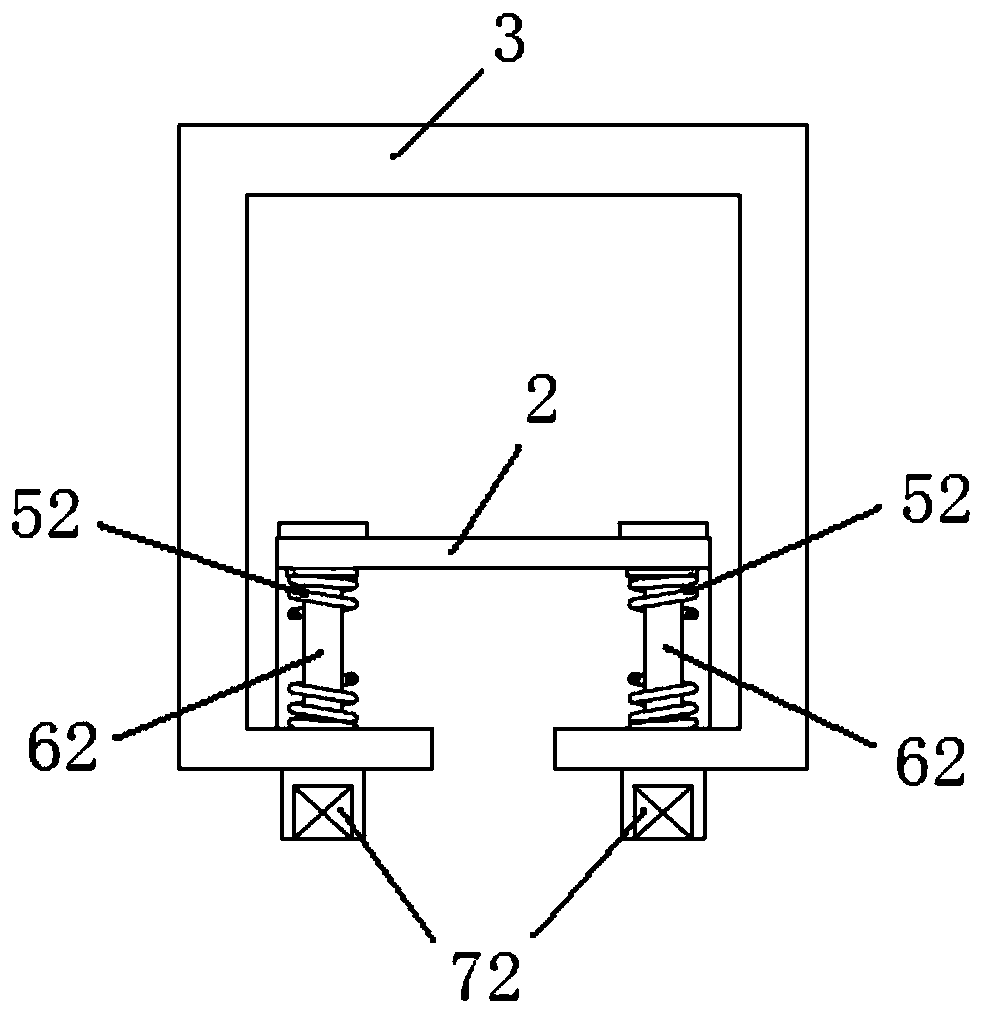

[0025] combine figure 1 As shown, the suspension train clamping brake device of the present invention includes a moving unit 1 and a clamping plate 2 .

[0026] The mobile unit 1 includes a brake trolley 11 and a friction plate 12 . The upper end of the brake trolley 11 is suspended on the track beam 3 and can move back and forth along the length direction of the track beam 3 . The lower end of the brake trolley 11 is provided with a buffer device 13 for contacting with the bumping pillar 41 at the front end of the train 4, thereby pushing the brake trolley 11 to move with the train 4.

[0027] Preferably, the center of the buffer device 13 is aligned with the center of the bumping top post 41 along the horizontal direction, so that the bumping top post 41 can accurately hit the center of the buffer device 13, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com