Processing platform relying on information technology and mathematical three-dimensional coordinate

A technology of three-dimensional coordinates and process processing, applied in the direction of electrical components, printed circuit manufacturing, printed circuits, etc., can solve problems such as ineffective effects, and achieve the effect of protecting health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

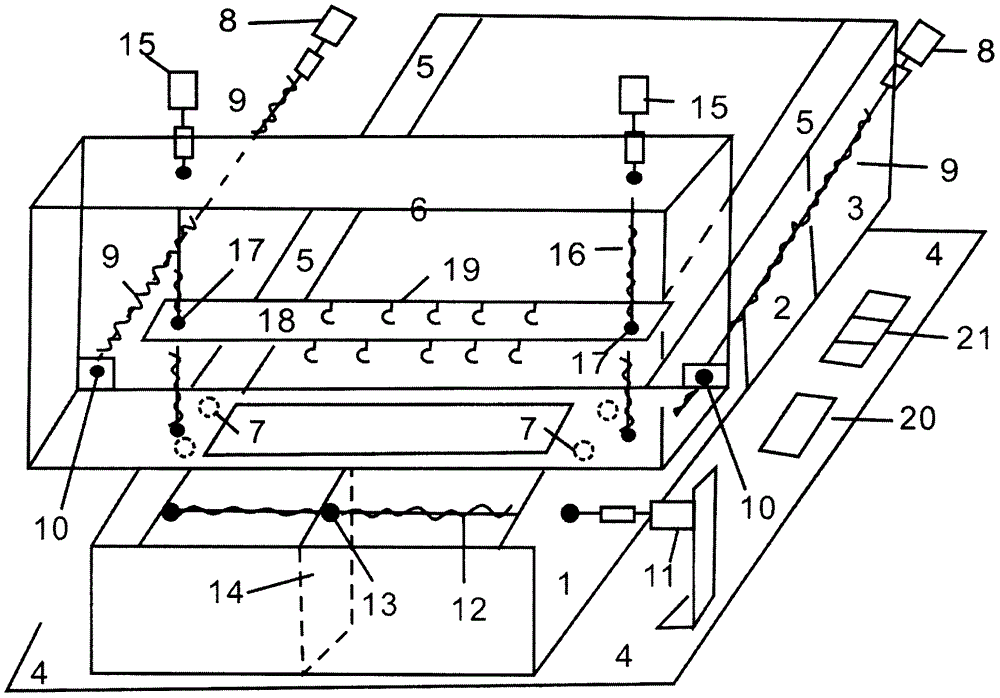

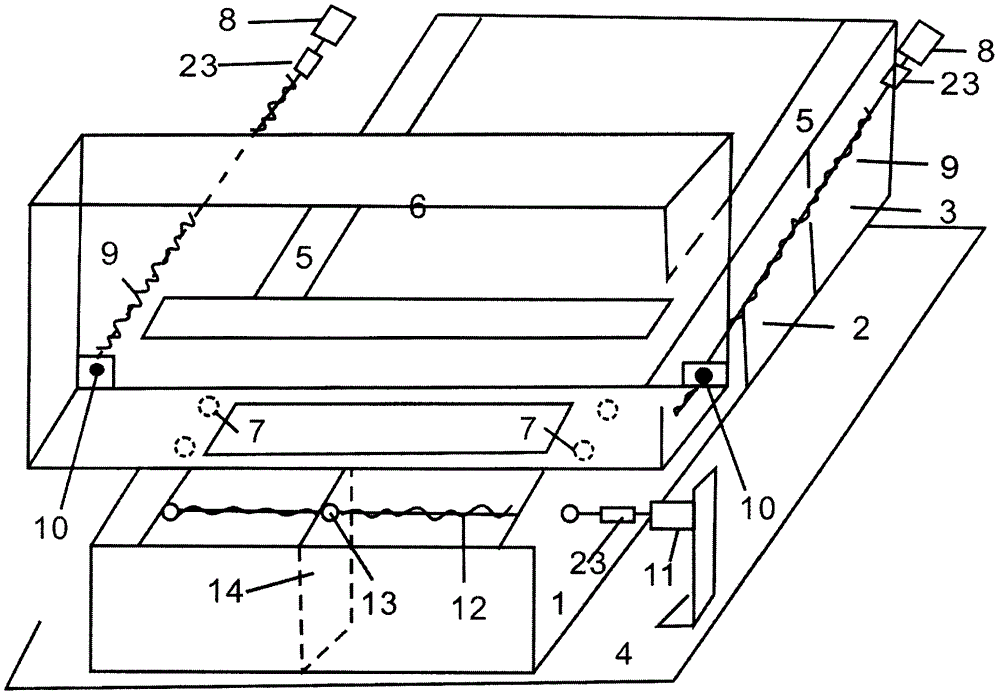

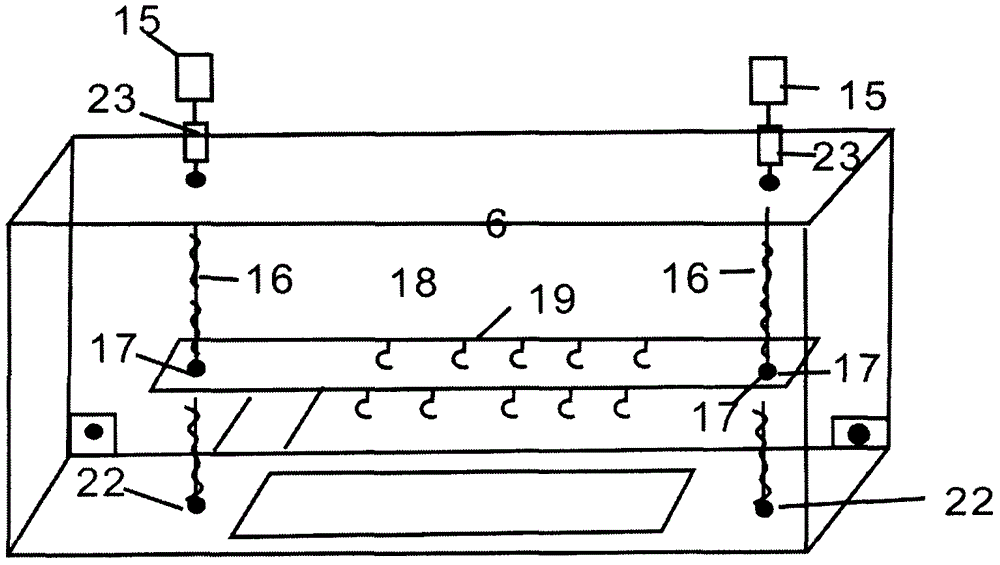

[0022] The three-dimensional movement of the present invention refers to: the liquid-dispelling plate (14) moves back and forth along the x-axis direction to drive the reaction liquid to flow; the small frame (18) rises or falls along the z-axis direction, so that the plate that needs to be etched is raised or lowered, so that The plate to be added is immersed in the liquid or lifted from the liquid; the large integrated frame (6) moves along the y-axis direction, so that the plate to be processed moves to the top of the reactor, the cleaner or the dryer. The three-dimensional movement is intelligently controlled by the single-chip microcomputer, and the finished product is sent out directly on the production line.

[0023] Make and install the following components:

[0024] A reactor (1), a washer (2), and a dryer (3) are connected together with intervals between them. The bottom of the above three containers is fixed to the base plate (4), and the top is fixed to the guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com