Dripping molding machine of chocolate

A drip pouring machine, chocolate technology, applied in cocoa, food science, application and other directions, can solve the problems of less research on small-granule chocolate production equipment, and the amount of pulp is difficult to meet the needs of small-granule chocolate, and it is easy to promote, The use effect is good, the effect of improving the uniformity of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

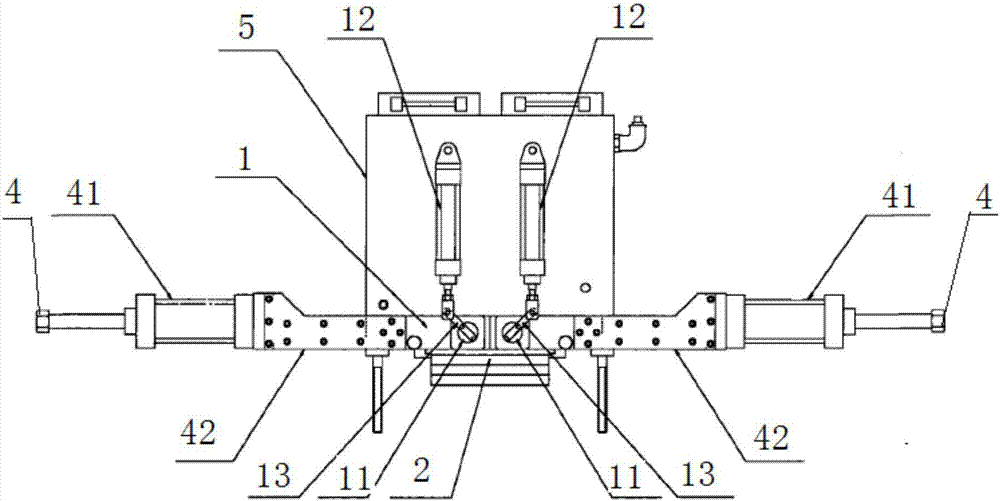

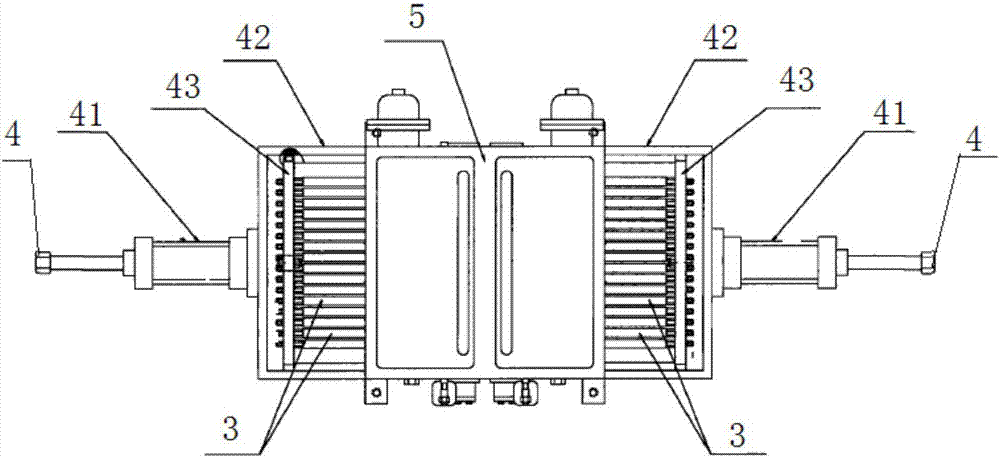

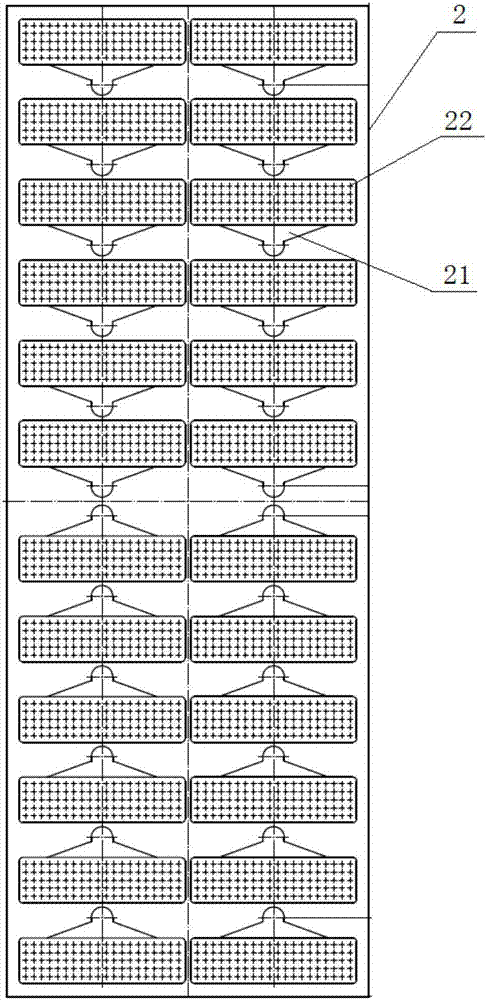

[0020] Embodiment 1: as Figure 1~3 The shown chocolate dripping machine is used for dripping small granular chocolate, and its structure includes a valve body 1, a distribution plate 2, several plungers 3, a plunger driving mechanism 4, a hopper 5, and the distribution plate 2 is located on the Below the valve body 1. The valve body 1 is provided with several valve cavities. The distribution plate 2 is provided with a blanking cavity 21 corresponding to each valve cavity. The blanking cavity 21 is conical, and its upper end communicates with the lower end of the valve cavity. Material hole 22. 60-150 discharge holes 22 may be provided on the lower end surface of the blanking cavity 21 . In this example, the distribution plate 2 is provided with 24 blanking chambers 21, and each blanking chamber 21 is provided with 100 discharge holes 22 on the lower end surface. The distribution plate 2 is detachably inserted under the valve body 1 .

[0021] The valve body 1 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com