A natural grading and balanced distribution method and device for wide particle size bulk materials

A bulk and balanced technology, applied in chemical instruments and methods, solid separation, grids, etc., can solve the problem of powder and block mixing, which is difficult to recover waste heat, and achieve easy operation, simple installation, and large bulk processing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0016] The invention aims at the problem that the mixture of powder and block in the high-temperature bulk material in the process industry is not easy to directly recover waste heat, etc., and provides a method and device for natural classification and balanced distribution of bulk materials with wide particle diameters.

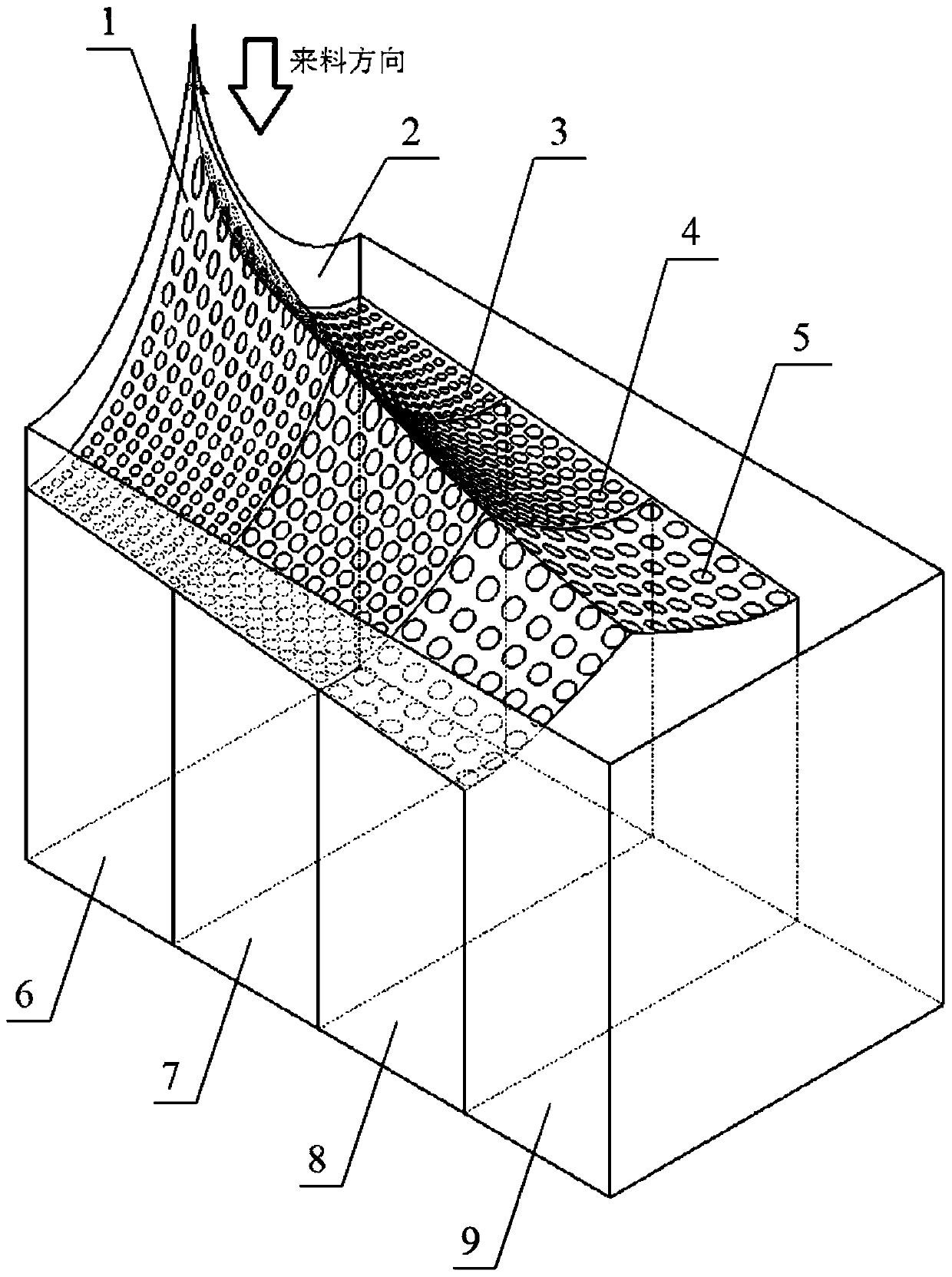

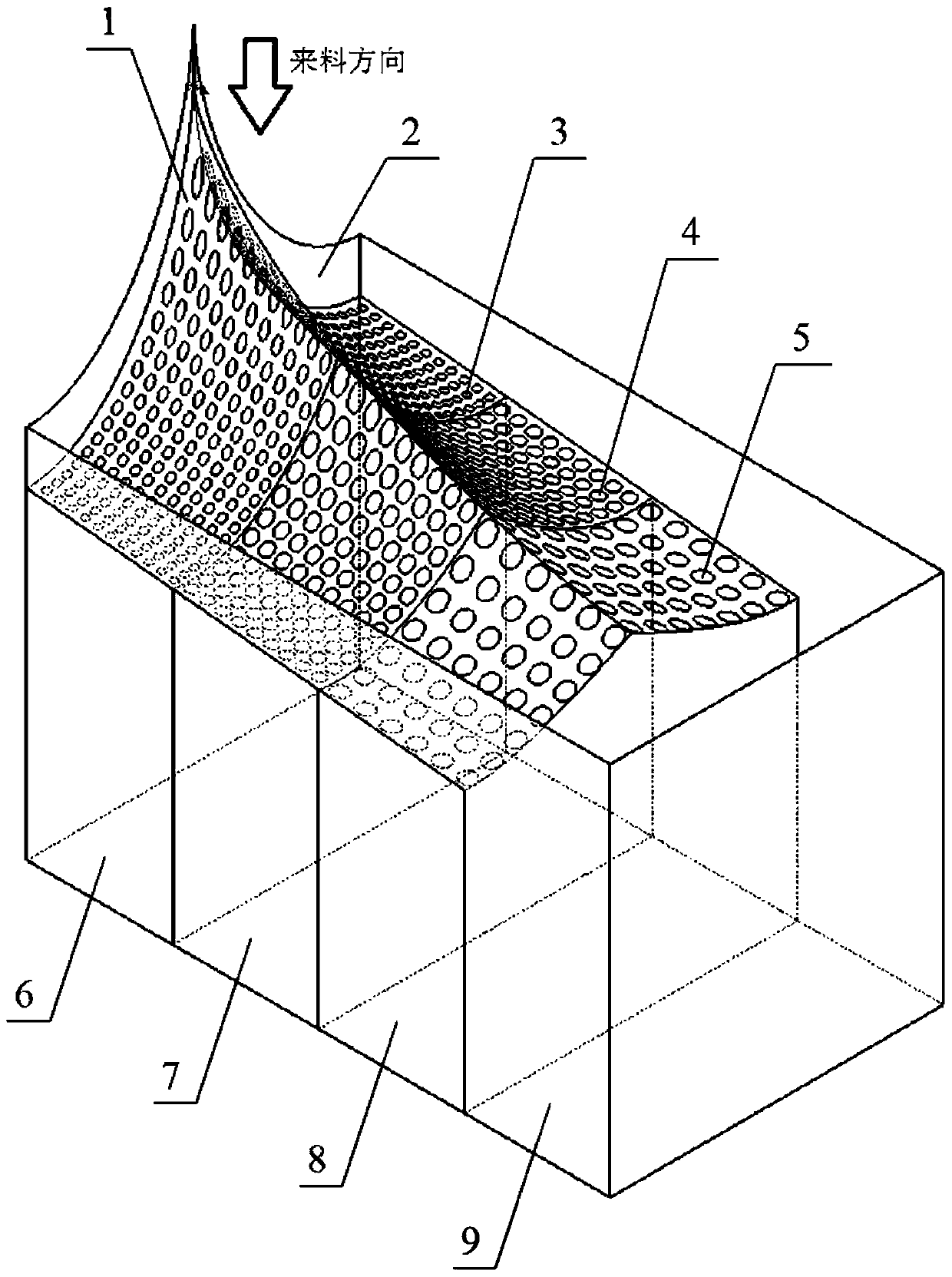

[0017] Such as figure 1 As shown, if the bulk material with particle size distribution between 0.1 and 20mm is to fall in a balanced manner and be divided into four grades of 0.1 to 1mm, 1mm to 3mm, 3mm to 8mm and 8mm to 20mm, a kind of Balanced cloth installation for natural grading. The device is equipped with a three-stage sieve hole and a four-stage material receiving bin, which realizes natural grading through the slope structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com