Electric saw

A technology of electric saw and motor shaft, applied in the field of reciprocating saw, can solve the problems of wear, reduce the effectiveness of the knife-lifting mechanism, reduce the service life of the knife-lifting mechanism, etc., and achieve the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

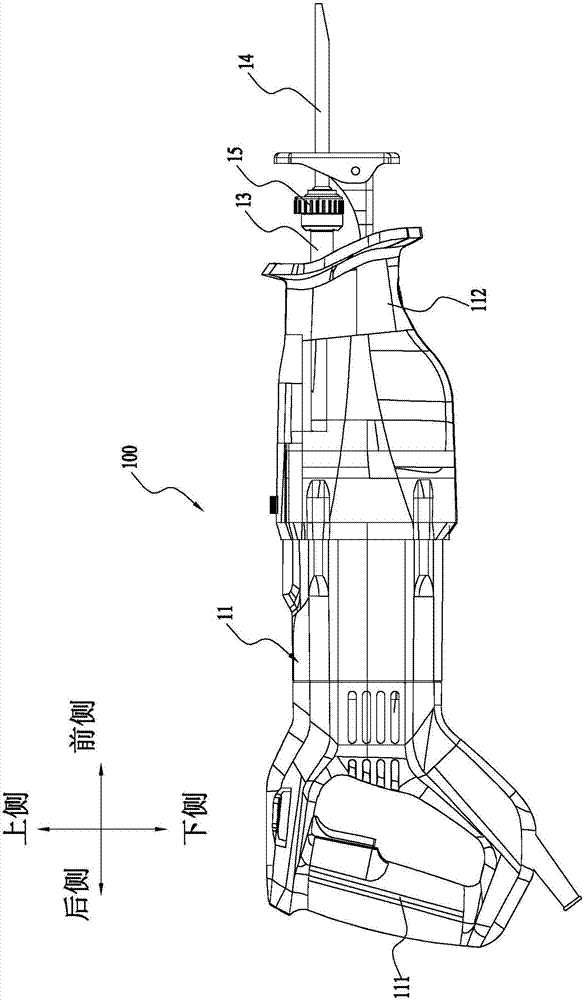

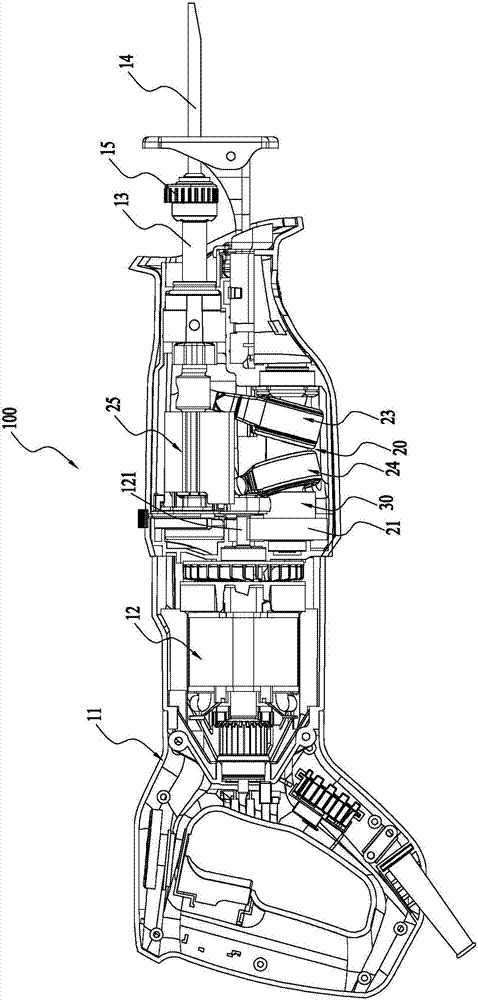

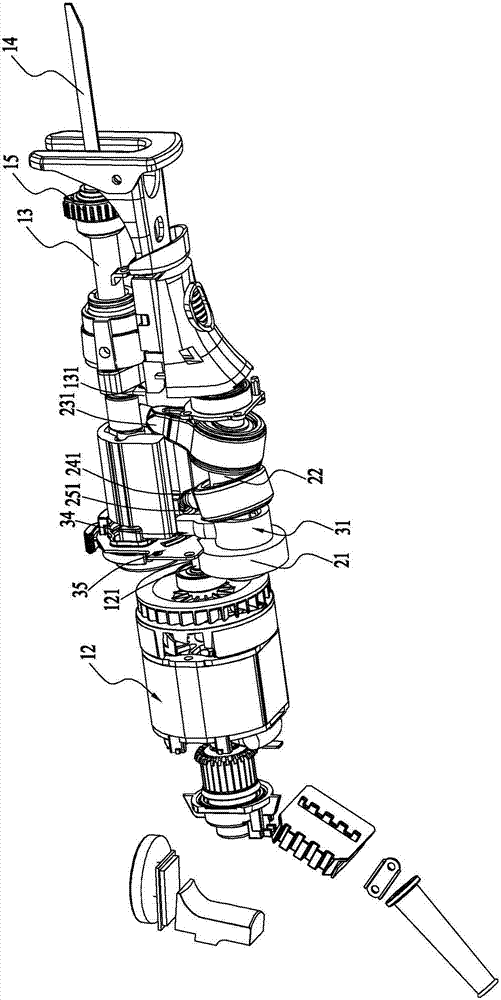

[0023] The present invention proposes an electric saw, which can be, for example, figure 1 The reciprocating saw 100 shown, figure 1 The reciprocating saw 100 of the illustrated embodiment can drive the saw blade 14 to reciprocate, so that the saw blade 14 can be used for sawing wood, metal and other objects. It can be understood that the chainsaw can also be other reciprocating saws, such as jigsaws, horse saws and the like.

[0024] Such as Figure 1 to Figure 3 As shown, the reciprocating saw 100 includes: a housing 11 , a motor 12 , a transmission mechanism 20 , a reciprocating rod 13 , a saw blade 14 and a knife lifting mechanism 30 . In order to facilitate and clearly explain the content of the technical solution, such as figure 1 As shown, the present invention also defines the upper side, lower side, front side, and rear side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com