Novel wheel die

A grinding wheel mold, a new type of technology, applied in the direction of manufacturing tools, metal processing equipment, grinding devices, etc., can solve the problems affecting the quality of the grinding wheel and reducing the service life of the mold, so as to ensure the production quality, reduce the mold materials, and reduce the size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

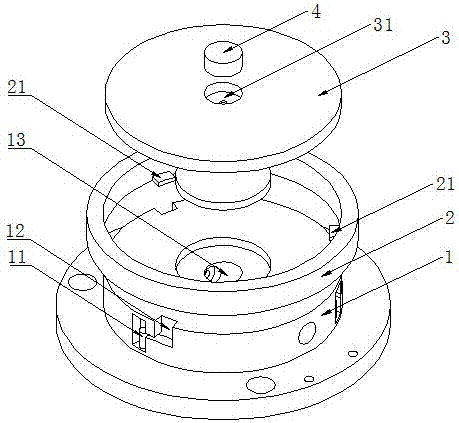

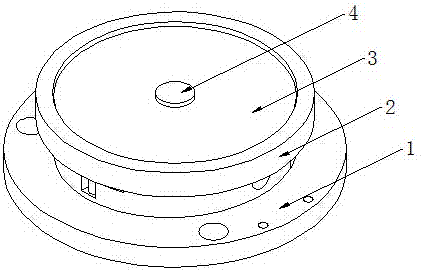

[0046] A kind of novel emery wheel mold of the present embodiment, as figure 1 , figure 2 , image 3 As shown, it is mainly realized through the following technical solutions: a new type of grinding wheel mould, including a bottom mold 1, an upper mold 2, an inner mold 3 and a core mold 4, and the core mold 4 is plugged into a core provided at the center of the top surface of the inner mold 3 In the hole 31; the bottom mold 1 includes a limit card groove 11, a limit elastic member 12 and a demoulding channel 13 arranged inside the bottom mold 1, and the side wall of the demoulding channel 13 is provided with auxiliary positioning holes; the limit card The slot 11 is in the shape of an inverted "h" and is arranged on the outer cylindrical surface of the bottom mold 1. The limit card slot 11 includes an installation slot 111 and a working slot 112 which communicate with each other. The limiting elastic member 12 is arranged in the working slot 112. One end of 111 is connected...

Embodiment 2

[0052] This embodiment is further optimized on the basis of the above embodiments, such as Figure 5 As shown, further, the first contact surface of the limit card is in contact with the second contact surface of the limit card groove, and a gap is provided between the inner ring surface of the upper mold and the outer cylindrical surface of the bottom mold. Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

Embodiment 3

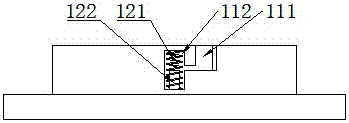

[0054] This embodiment is further optimized on the basis of the above embodiments, such as Figure 4 , Figure 5 As shown, further, the bottom mold 1 includes a plurality of limit elastic members 12, and the plurality of limit elastic members 12 are evenly distributed on the outer cylindrical surface of the bottom mold 1; the limit elastic members 12 include limit columns and elastic The connecting piece 122, the limiting column is a rigid cylinder, the elastic connecting piece 122 is sleeved on the limiting column and the upper end surface of the elastic connecting piece 122 is higher than the upper end surface of the limiting column; the upper end surface of the elastic connecting piece 122 is in contact with the limiting column The bottom surface of the bit card 21 is in contact with the bottom surface of the elastic connecting member 122 and the bottom surface of the working slot 112 . Other parts of this embodiment are the same as those of the foregoing embodiments, so d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com