3D film attaching equipment and 3D film attaching method

A film sticking equipment, 3D technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of high product defect rate, inability to 3D glass lamination, easy to contaminate the film, etc., to improve the quality of the film Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following exemplary embodiments and descriptions are only used to explain the present invention, not as a limitation to the present invention, and, in the case of no conflict, the embodiments in the present invention and the features in the embodiments can be combined with each other .

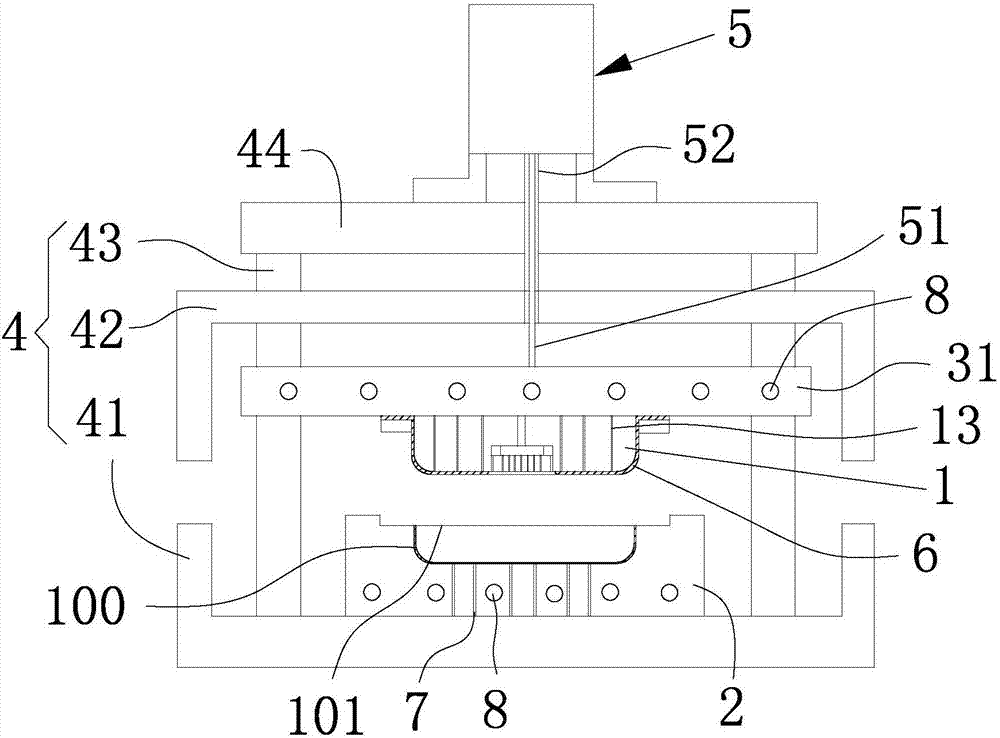

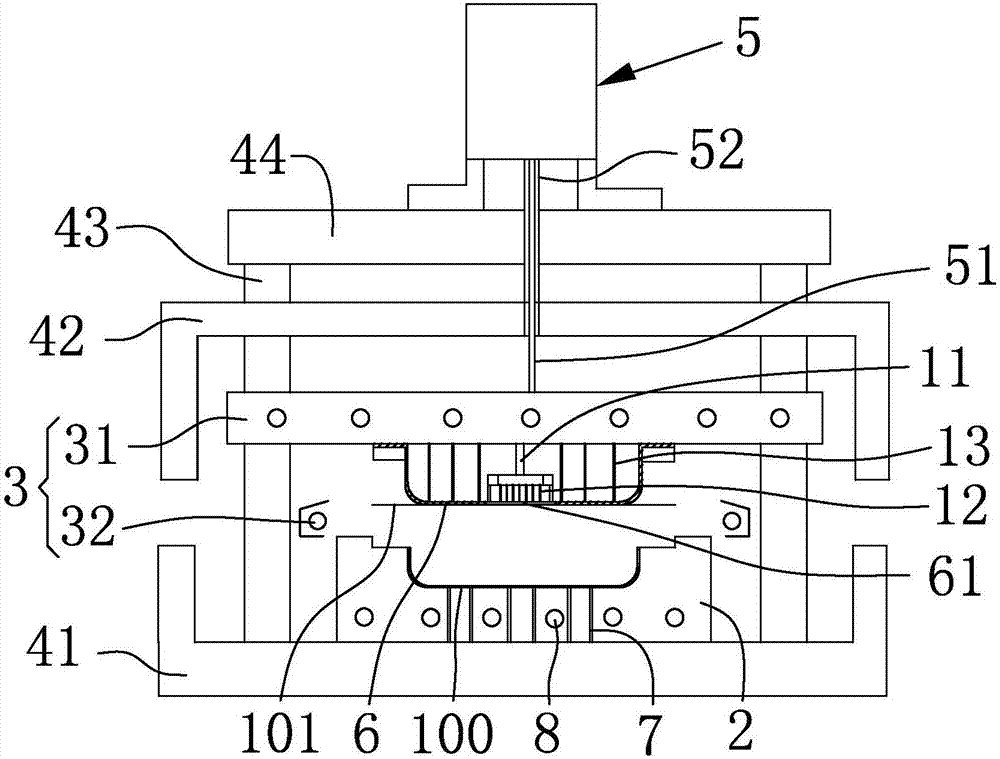

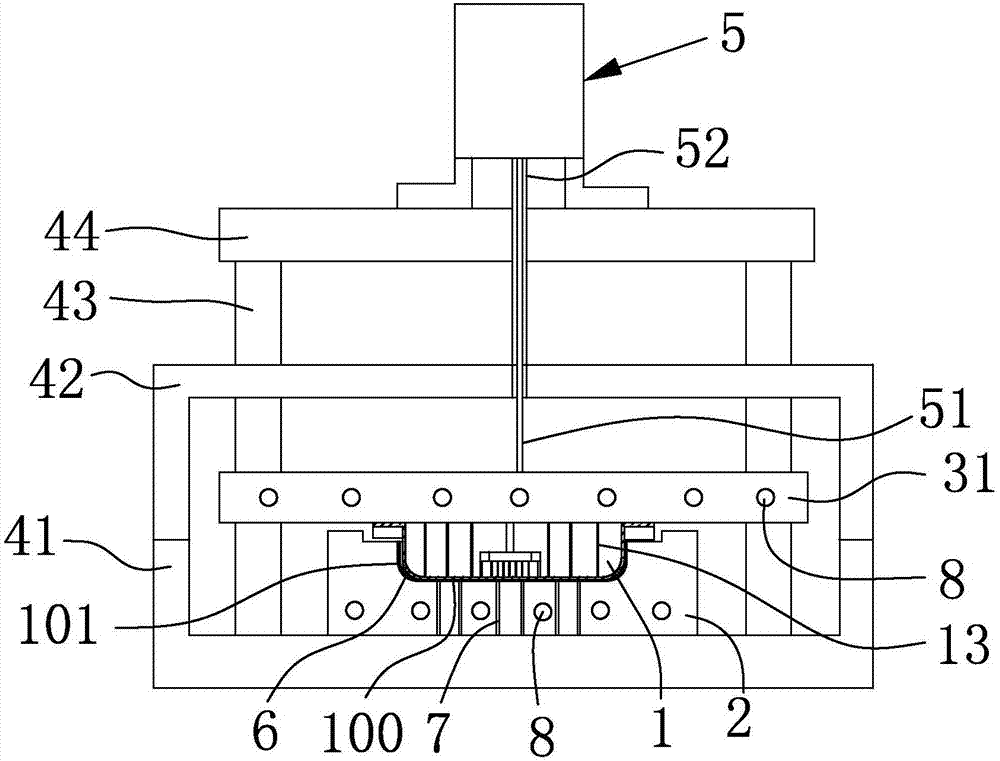

[0037] An embodiment of the present invention provides a 3D film sticking device, which can be used for sticking a film on the surface of a 3D workpiece, and the 3D workpiece can be a 3D glass panel or the like. Such as Figure 1 to Figure 3 As shown, the 3D film sticking equipment provided by the embodiment of the present invention includes a core 1, a cavity 2 for accommodating a workpiece 100 to be filmed, a heating device 3 for heating the core 1, the cavity 2 and the diaphragm 101, A sealed chamber 4 for accommoda...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap