Printer ink supply system provided with inflating piezoelectric pump

A piezoelectric pump and printer technology, applied in printing and other fields, can solve problems such as unstable ink output from the nozzle, high requirements on the position of the outer ink bottle, inconvenient installation and maintenance of the ink supply system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

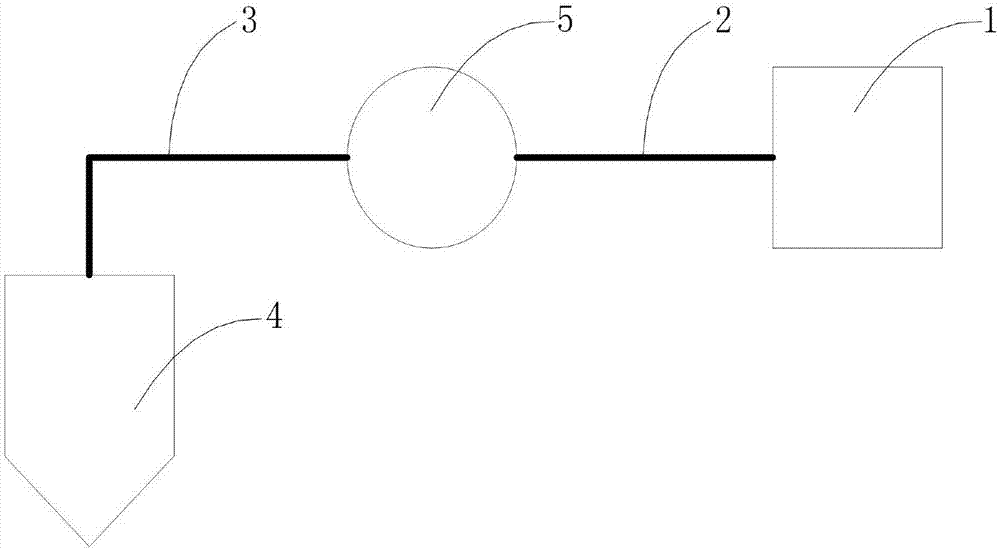

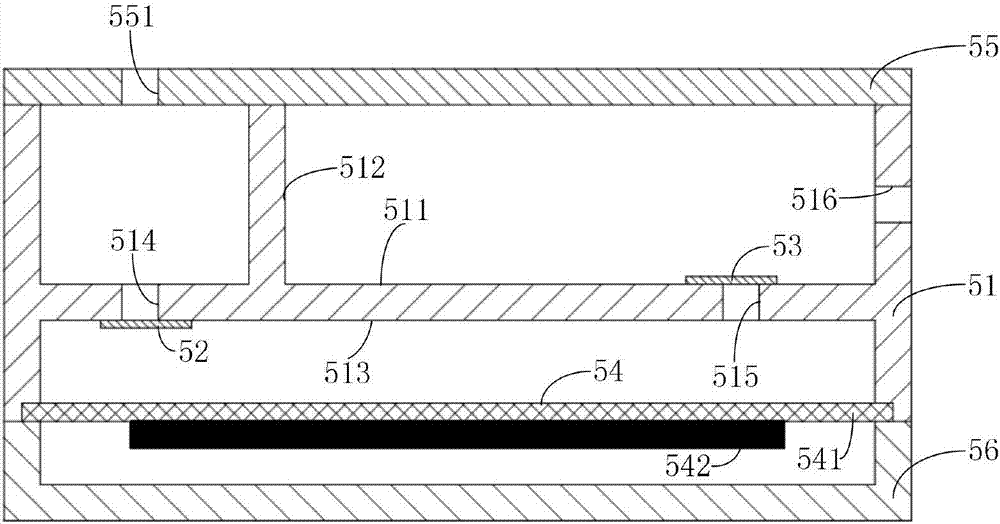

[0009] refer to figure 1 and figure 2 , a printer ink supply system with a pressurized piezoelectric pump of the present invention is composed of an ink cartridge 1, a first connecting pipe 2, a second connecting pipe 3, a nozzle 4 and a piezoelectric pump 5, wherein:

[0010] The piezoelectric pump 5 includes a pump body 51, an ink inlet valve plate 52, an ink outlet valve plate 53, a piezoelectric vibrator 54, a top cover 55 and a bottom cover 56; the pump body 51 is a cylindrical member, and its A circular sinker 511 is arranged in the center of the upper surface, and a longitudinal partition 512 is arranged in the circular sinker 511 to separate the circular sinker 511 into two unclosed cavities, the first cavity and the second cavity. A circular sinking groove 513 is arranged in the middle of the lower surface to form an unclosed third cavity; the bottom surface of the first cavity is arranged with an ink inlet hole 514 communicating with the first cavity and the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com