Mechanical elevator stopping device

A mechanical blocking and elevator technology, applied in elevators, transportation and packaging, etc., can solve problems such as low efficiency and poor blocking effect, and achieve high efficiency and good blocking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

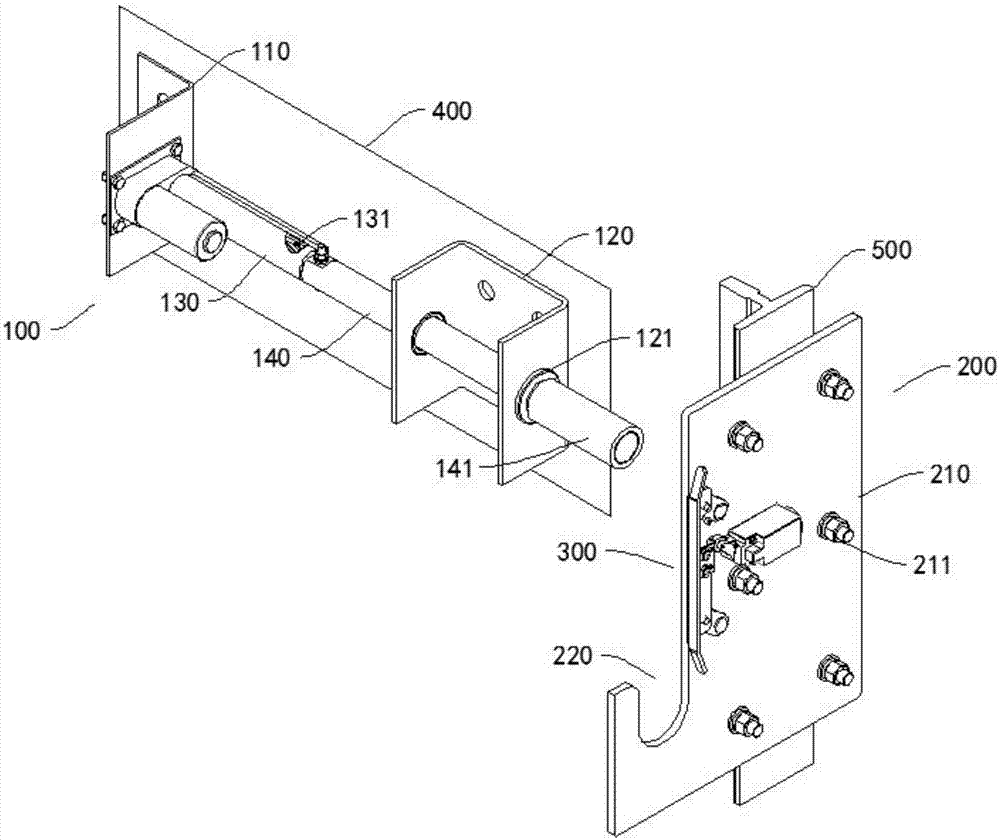

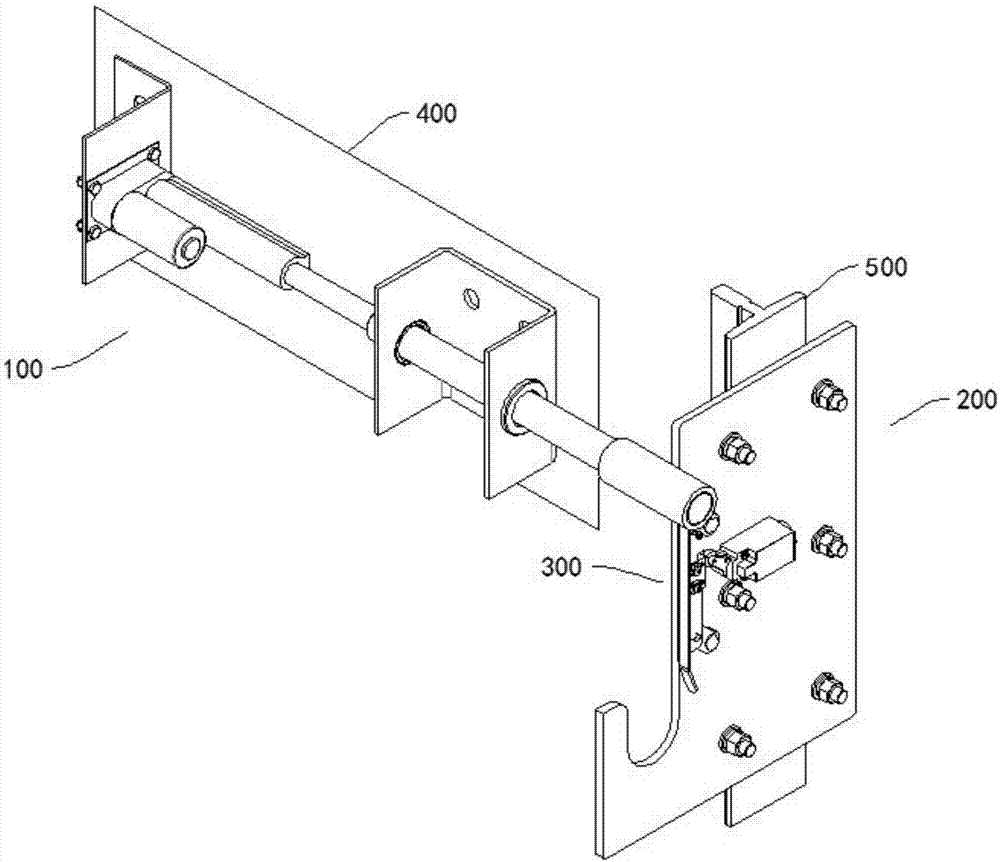

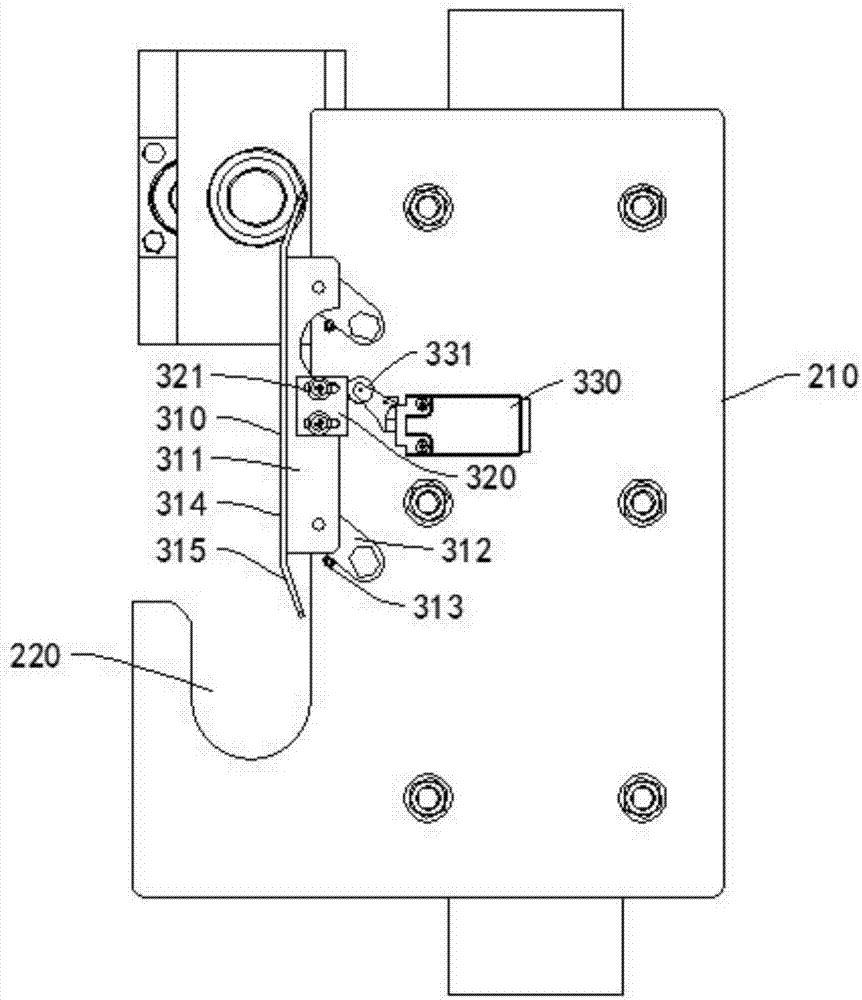

[0022] Embodiment: elevator mechanical stopping device, constitutes as Figure 1 to Figure 3 As shown, it includes a trigger device 100 fixed on the car frame 400 and a load-bearing device 200 fixed on the car guide rail 500; the trigger device 100 includes an electric push rod bracket 110, and the electric push rod bracket 110 is provided with an electric Push rod 130, the side of electric push rod support 110 is provided with load-bearing rod support 120, is provided with load-bearing rod 140 on load-bearing rod support 120, and described electric push rod 130 is connected with load-bearing rod 140; Described electric push rod The support 110 and the load-bearing rod support 120 are fixed on the car frame 400; the trigger device 100 also includes a position switch 131; the load-bearing device 200 includes a stop plate 210 opposite to the load-bearing bar 140, and the stop plate 210 The fixing device 211 is fixed on the car guide rail 500 , the stop plate 210 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com