Post-grouting strip-shaped partitioning barrier for super large area pressure bearing plate and partitioning method thereof

A super-large area, pressure-bearing plate technology, used in bridge parts, bridges, buildings, etc., can solve the problems of large application limitations, poor separation and airtightness, and poor quality stability of post-grouting technology, and achieve easy construction quality and low cost. , The effect of stable grouting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

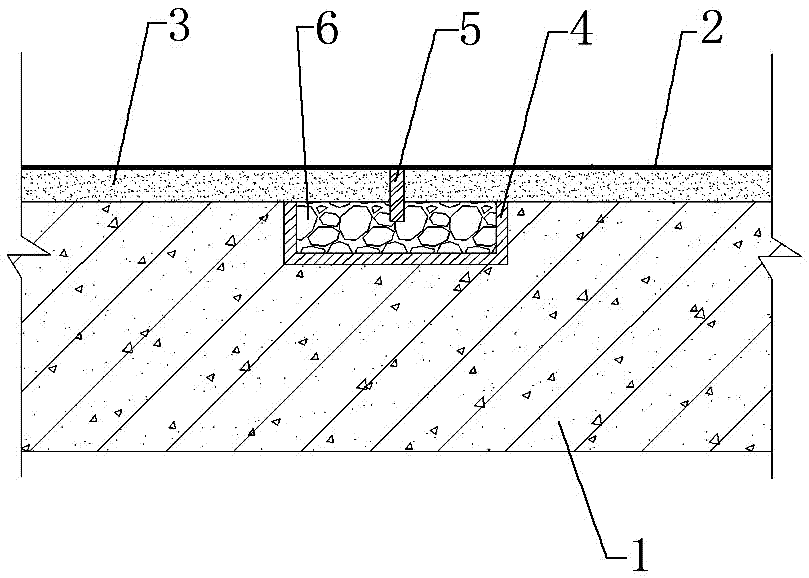

[0028] like figure 1 As shown, the post-grouting strip-shaped silo barrier barrier used for the super-large area bearing plate of the present invention is evenly spaced in the gap between the concrete foundation 1 and the bearing plate 2, and the gap is poured with a joint filler 3, which is divided into two parts. The silo barriers are arranged side by side and are arranged in a full length, including the base 4 embedded on the concrete foundation 1, the vertical partition 5 located in the middle of the base 4 and the grouting material 6 filled in the base 4. The base 4 is of different specifications. For channel steel less than 10#, the notch is vertically upward, and the edge of the leg plate is set flush with the upper surface of the concrete foundation 1; the spacer is evenly arranged between the concrete foundation 1 and the bearing plate 2, and the concrete foundation 1 and the bearing plate are evenly arranged. The width of the gap between 2 is 5-7cm; the vertical part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com